Steel bridge deck protecting device and production method thereof

A protection device and production method technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of delamination and slippage between bridge deck and asphalt concrete surface layer, poor durability of interlayer bonding, poor high temperature stability, etc. Achieve the effect of enhanced interlayer adhesion durability, reduced damage, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

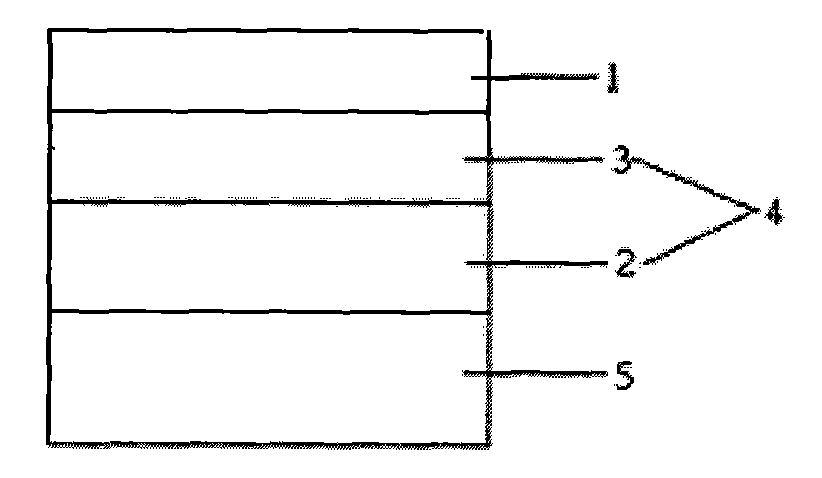

[0033] Such as figure 1 As shown, it is a longitudinal section schematic diagram of the structure of the steel bridge deck protection device of the present invention. The steel bridge deck protection device of the present invention includes the bottom layer arranged on the steel bridge deck, that is, the asphalt concrete surface layer 1 on the bridge deck 5, and also includes A layer of bonding transition layer 4 arranged between the bridge deck 5 and the asphalt concrete surface layer 1, the bonding transition layer 4 includes a graded crushed stone layer 3 mixed with epoxy resin and polyurethane A binder layer 2, the graded crushed stone layer 3 is arranged on the binder layer 2 and under the asphalt concrete surface layer 1 .

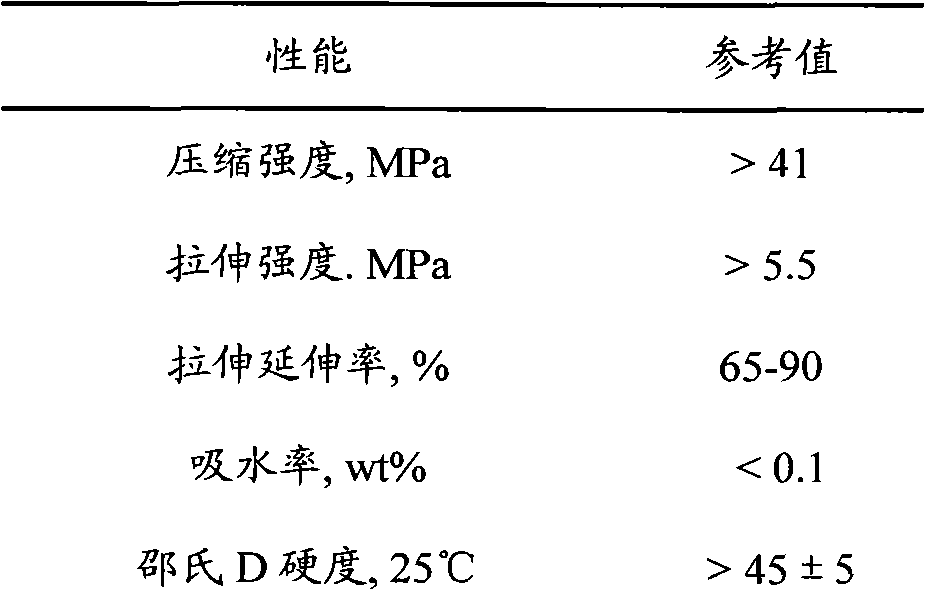

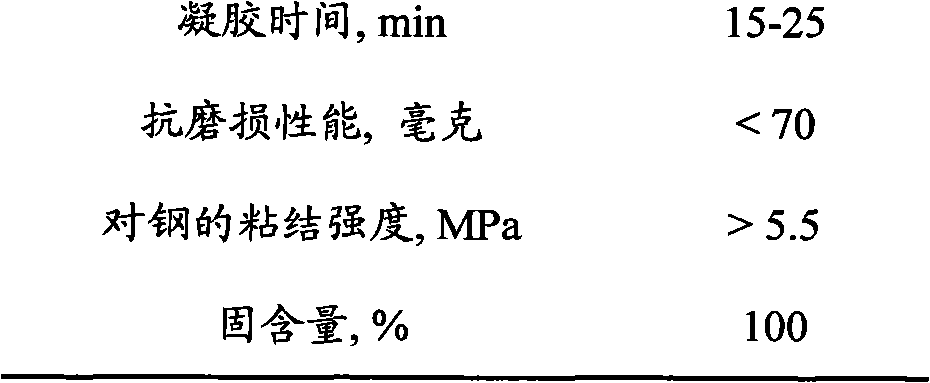

[0034] In this embodiment, the adhesive formed by compounding epoxy resin and polyurethane is purchased from U.S. dow chemical company, and its trade name is FLEXOGRID system, which can be Mark-166.2 (A component: B component=1: 1, dosage : 1.35 lit...

Embodiment 2

[0058] Other structures of the steel bridge deck protection device in this embodiment are the same as those in Embodiment 1, except that two bonding transition layers are arranged between the bridge deck and the asphalt concrete surface.

[0059] Its production method is all identical with embodiment 1 except repeating step (3) and step (4) after step (4).

[0060] The steel bridge deck protection structure of this embodiment also has extremely high guarantees for high temperature stability, fatigue crack resistance, followability to steel plate deformation, deformation characteristics, interlayer bonding, and a complete waterproof and drainage system. It is easy to maintain, and has the advantages of wear resistance, anti-skid, waterproof, good anti-aging performance, large deformation, small weight, long service life, and simple and convenient maintenance. The specific experimental results are omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com