Methane locking alarm

A technology of alarm, sound and light alarm, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of gas explosion, hidden danger, detonator does not have methane gas detection function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

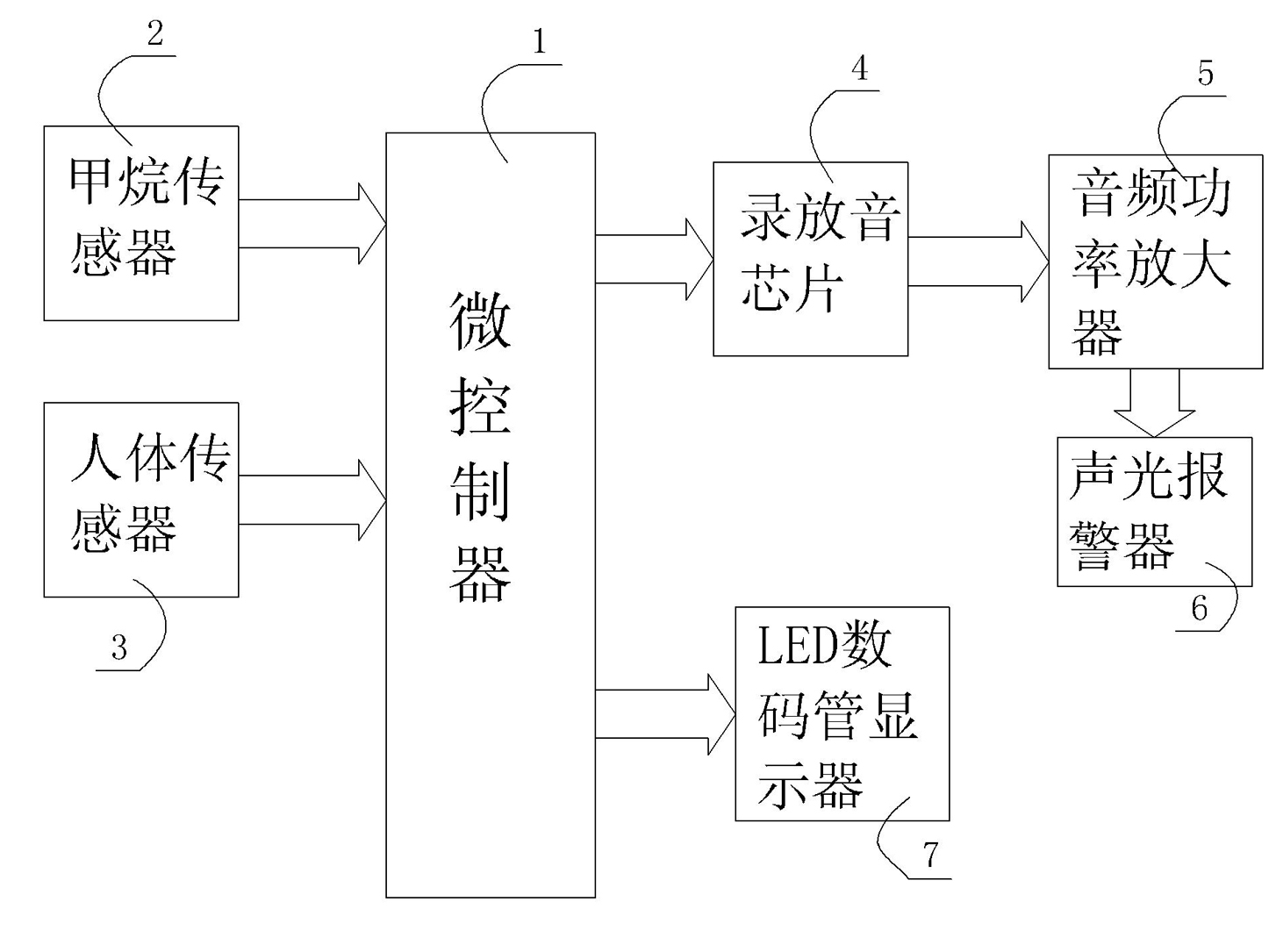

[0012] Such as figure 1 As shown, the principle diagram of the methane blocking alarm of the present invention is provided, including a microcontroller 1, a methane sensor 2, a human body sensor 3, a recording and playback chip 4, an audio power amplifier 5, an acousto-optic alarm 6, and an LED digital tube monitor. The microcontroller 1 is used to detect and calculate the input signals of the methane sensor 2 and the human body sensor 3, the methane sensor 2 can detect the methane gas concentration in the mine area, and the human body sensor 3 is used to detect the personnel in the mine area, record and play The sound chip 4 can realize the recording and playing of the alarm prompt sound. The audio power amplifier 5 can amplify the alarm signal so as to attract the attention of the staff.

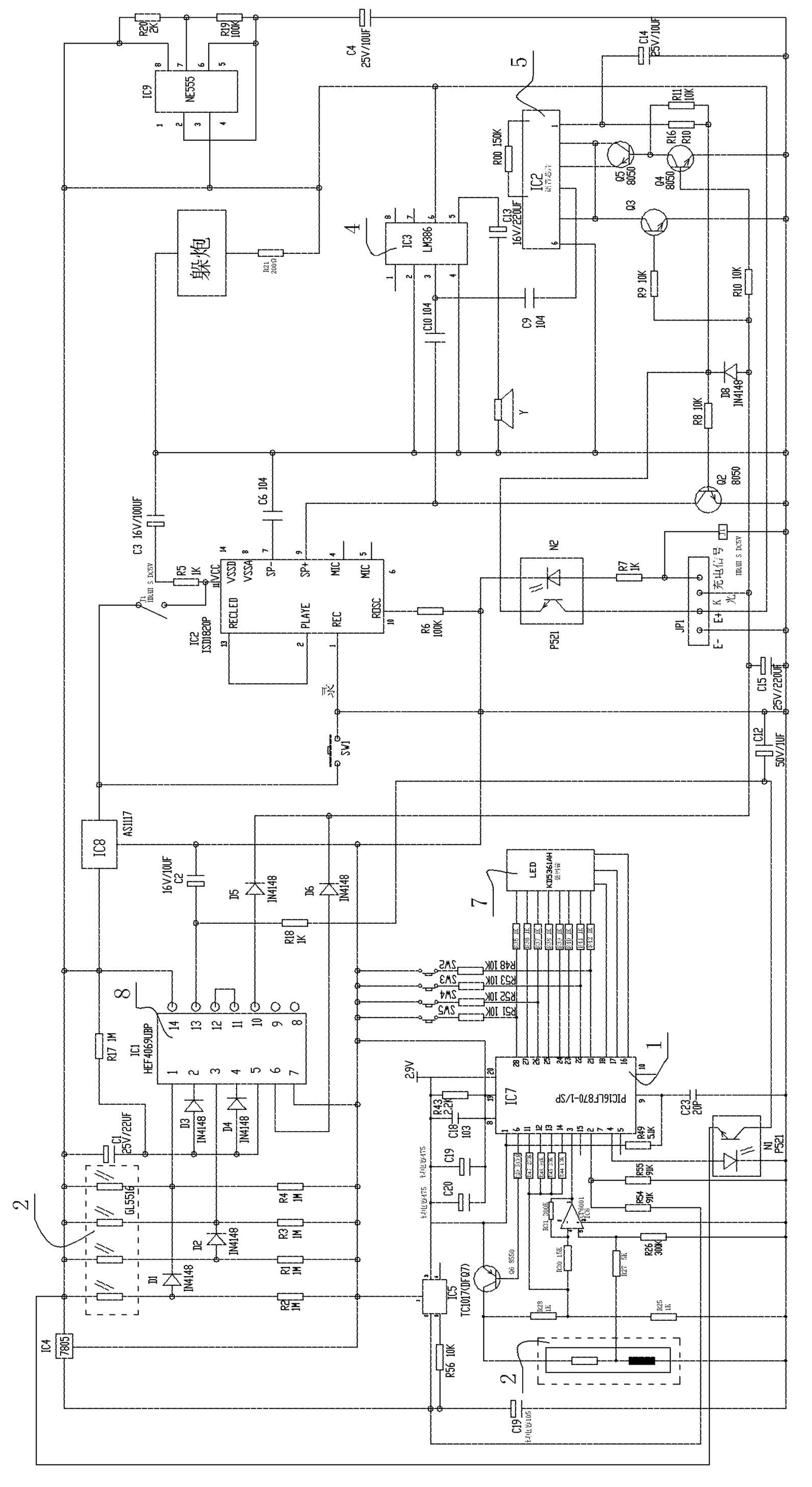

[0013] figure 2 The circuit diagram of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com