Anti-mist high-efficient evaporative mixed-flow condensing method and condenser

An evaporative and condenser technology, which is applied in the field of exhaust steam condensation, can solve the problems of general condensation effect, poor heat transfer effect, and low power generation efficiency, and achieve the effects of eliminating white fog, small water consumption, and large latent heat of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

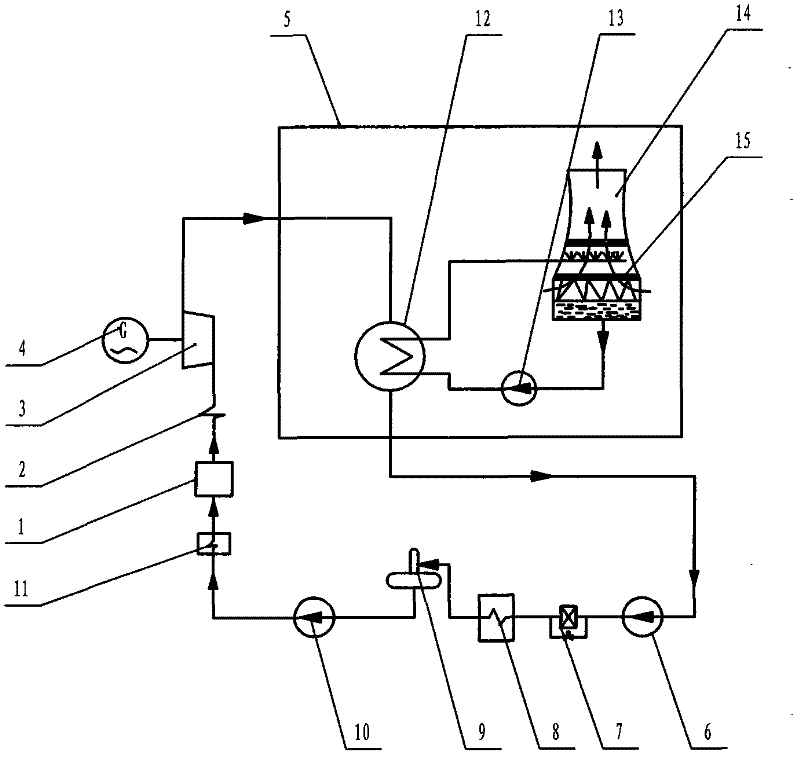

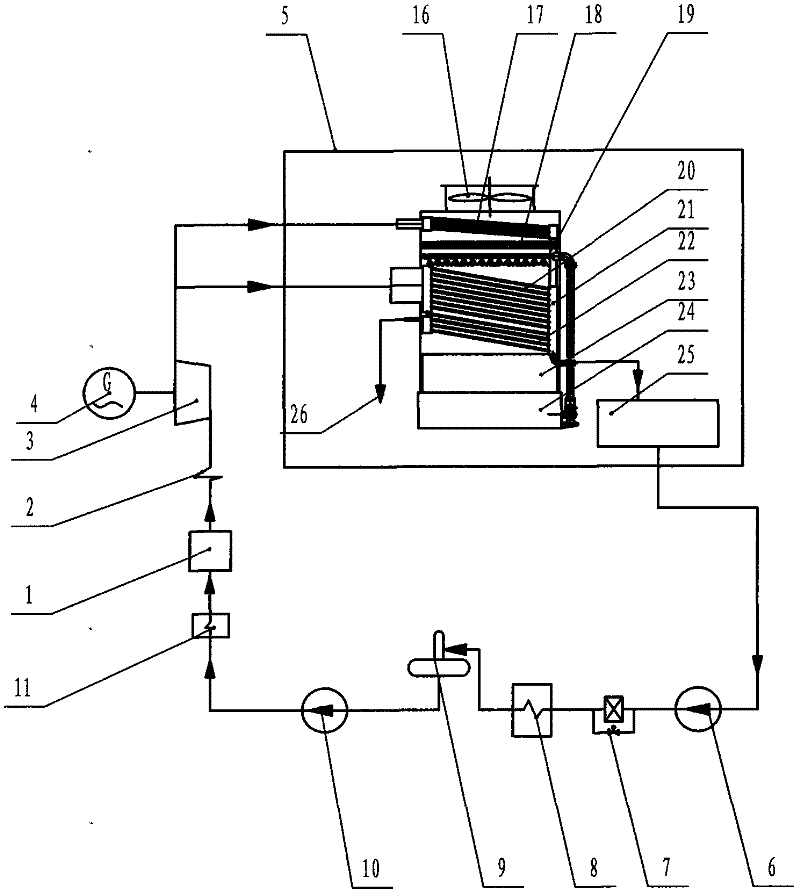

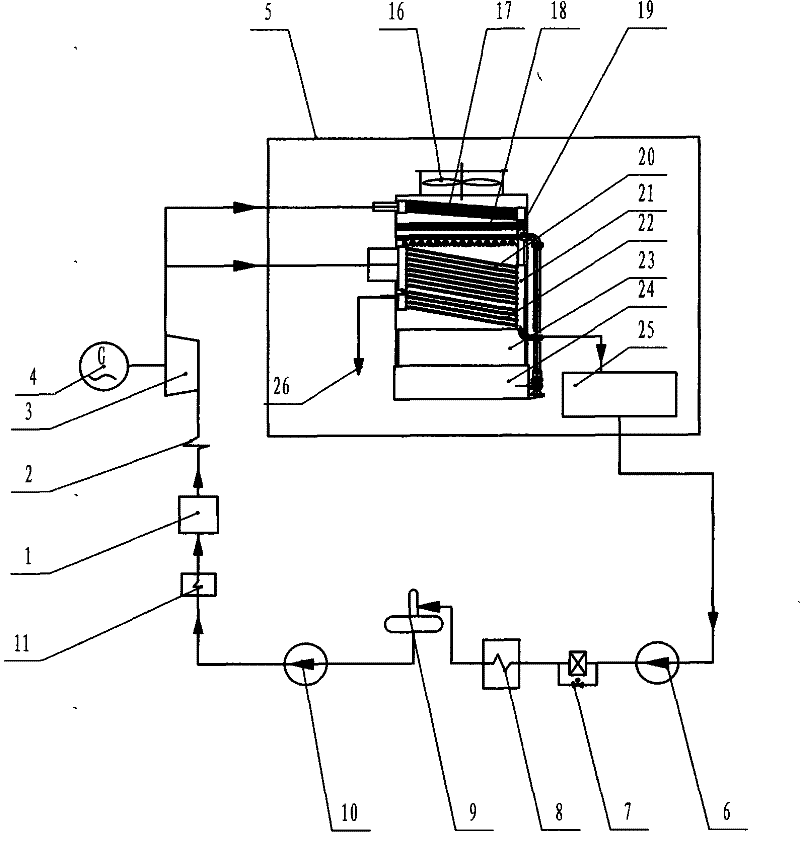

[0024] Such as figure 2 Shown: an anti-white fog evaporative mixed-flow condensation method,

[0025] 1. Adopt the method of mixed flow condensing steam with the anti-white fog area as the upper part, the main condensing area as the middle, and the auxiliary condensing area as the lower part. The exhaust steam of the steam turbine is sent to the downstream tube bundle of the main condensing area by two steam distribution pipes respectively. The downstream tube bundle 17 in the anti-white mist area operates in a downstream mode; the countercurrent tube bundle 22 in the auxiliary condensation area operates in a countercurrent mode;

[0026] 2. Through the spray system 19 above the main condensing area, water is evenly sprayed onto the tube bundles in the main condensing area and the auxiliary condensing area, and a water film is formed on the outer surface of the tubes. After the water film absorbs heat, it partially evaporates and condenses the saturated steam in the tube. fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com