Clamping welding machine head

A machine head and welding machine technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as uncontrollable gaps, poor welding, bending deformation, etc., to improve stability and authenticity, improve Improvement of welding quality and overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

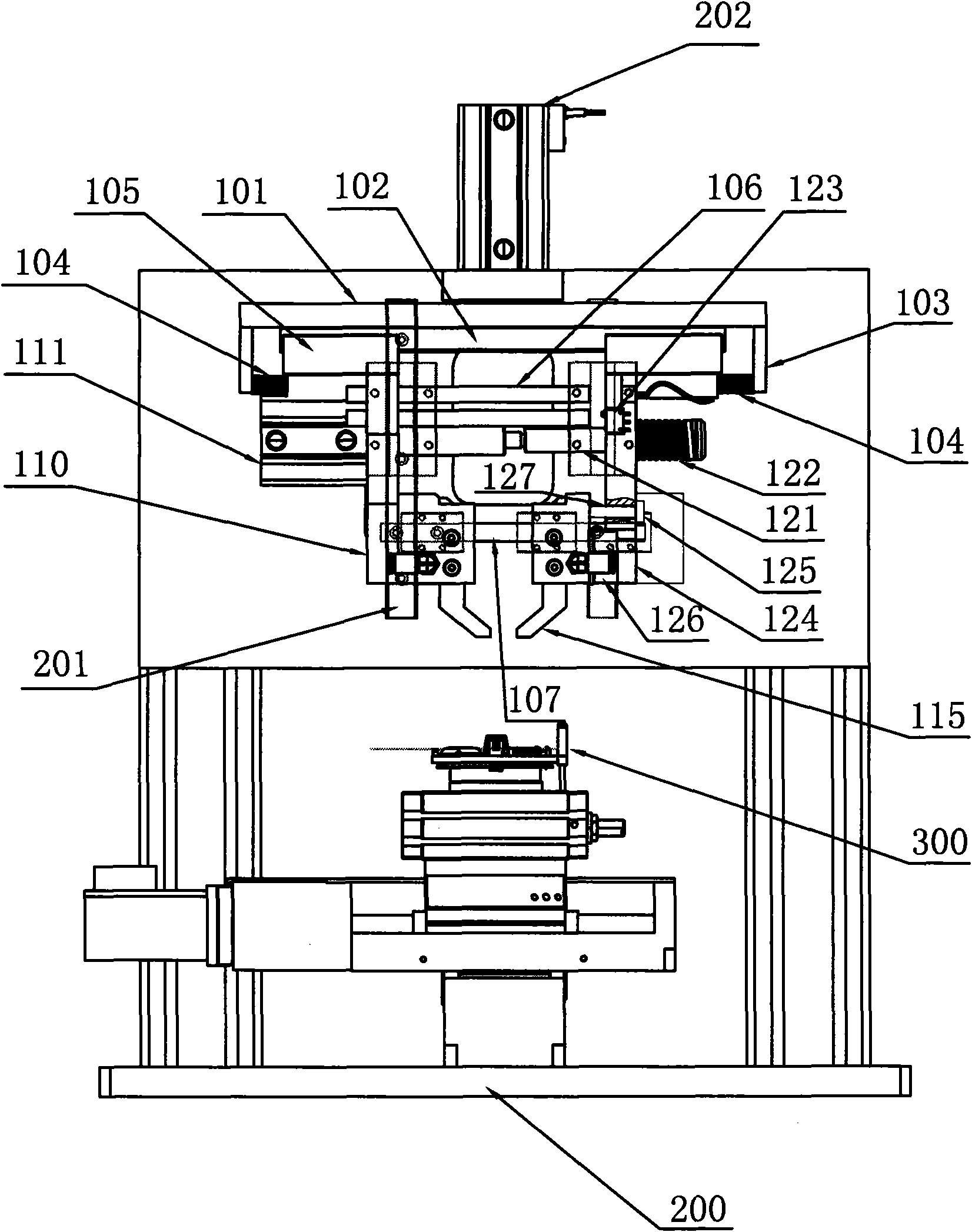

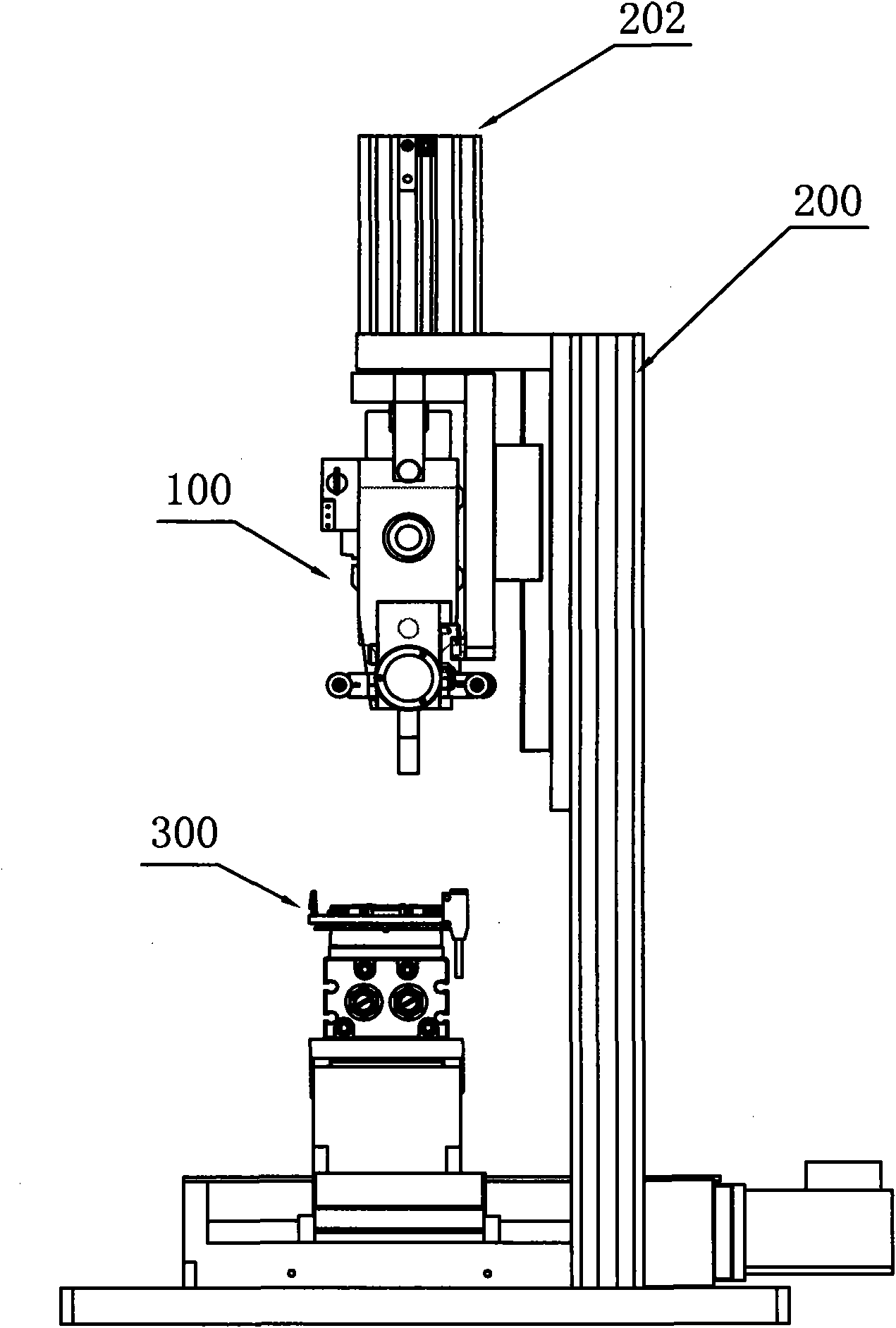

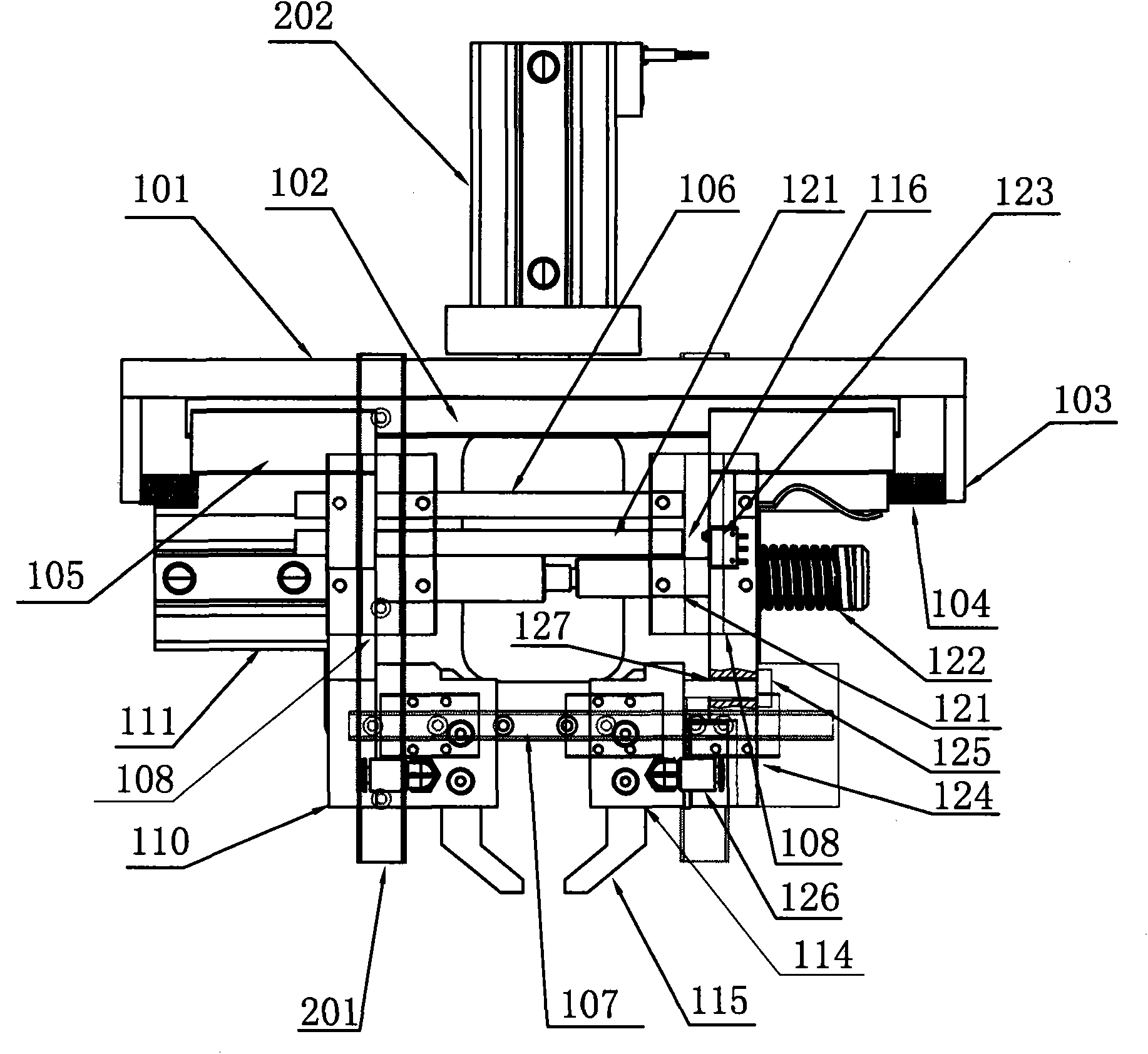

[0021] control figure 1 , welding machine head 100 of the present invention is mainly made of clamping frame 101, guide rail 102, two supports 110, two balance springs 103, two electrodes 115, cylinder 111 (or servo motor), pull rod 121, feedback board 116, displacement sensor 123, compression spring 122 and pressure sensor 124 form. The machine head 100 is slidably connected with the vertical guide rail 201 on the resistance welding machine frame 200 through two vertically distributed and spaced sliders 108 on the rear side of the clamping frame 101, so that the clamping frame 101 is placed horizontally. The piston rod of the cylinder 202 fixed on the welding machine frame 200 is connected with the upper end of the clamping frame 101, and pushes the welding machine head 100 to move up and down along the vertical guide rail 201 through telescopic movement.

[0022] The lower side of the upper end plate of the clamping frame 101 is provided with a guide rail 102, and two slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com