Single-component chlorosulfonated polyethylene anticorrosive paint and preparation method thereof

A technology of chlorosulfonated polyethylene and anti-corrosion coatings, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of affecting the storage stability of coatings, potential safety hazards, and high energy consumption, and achieve improved anti-corrosion performance and Other performance, less energy consumption, and the effect of increasing profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of chlorosulfonated polyethylene resin solution:

[0039] CSM-30 Chlorosulfonated Polyethylene Resin 30.0kg

[0040] Toluene 70.0kg

[0041] The preparation process of the chlorosulfonated polyethylene resin solution is as follows:

[0042] (1) The reactor is a reactor equipped with a stirrer, a thermometer, a condensation device, and a temperature control device.

[0043] (2) Add toluene into the reaction kettle, add CSM-30 chlorosulfonated polyethylene resin with stirring, stir and heat to dissolve, and control the temperature at 60-70°C.

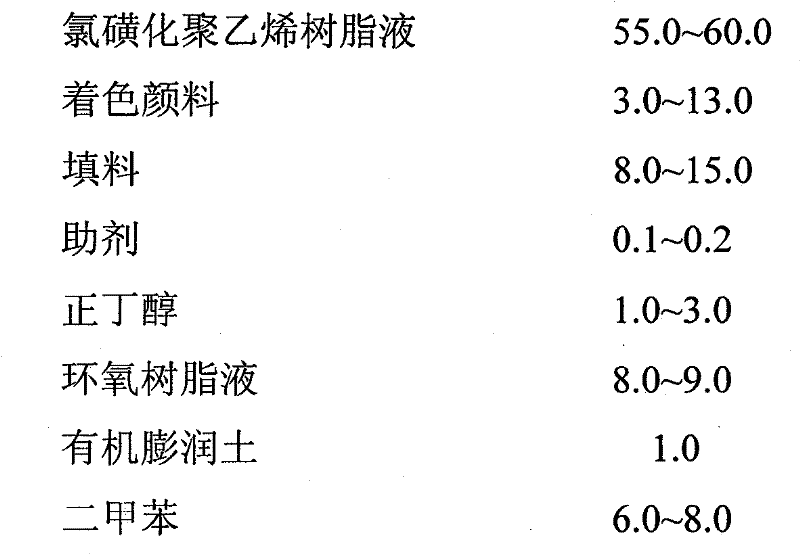

[0044] (3) Heat and dissolve until the resin liquid has a fineness of ≤25μm, cool down, filter, discharge, and set aside. Preparation of white one-component chlorosulfonated polyethylene topcoat:

[0045] 30% chlorosulfonated polyethylene resin liquid 60.0kg

[0046] Titanium dioxide 13.0kg

[0047] Packing 8.0kg

[0048] Epoxy resin liquid 8.0kg

[0049] Organic bentonite 1.0kg

[0050] N-butanol 2.0kg

[0051] 1% D201 silicone oil 0.1...

Embodiment 2

[0058] Preparation of chlorosulfonated polyethylene resin solution:

[0059] CSM-30 Chlorosulfonated Polyethylene Resin 30.0kg

[0060] Toluene 70.0kg

[0061] Operate according to the preparation steps of the resin solution in Example 1.

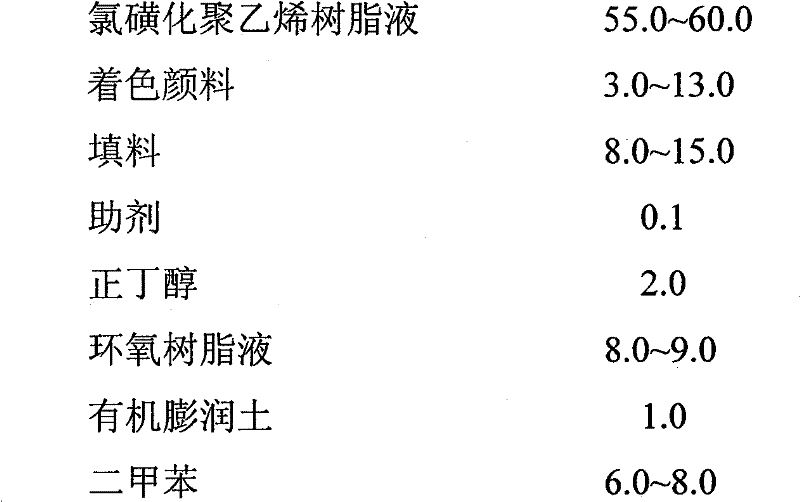

[0062] Preparation of iron red single-component chlorosulfonated polyethylene primer:

[0063] 30% chlorosulfonated polyethylene resin liquid 55.0kg

[0064] Iron oxide red 12.0kg

[0065] Packing 15.0kg

[0066] Epoxy resin liquid 9.0kg

[0067] Organic bentonite 1.0kg

[0068] N-butanol 2.0kg

[0069] 1% D201 silicone oil 0.1kg

[0070] Xylene 6.0kg

[0071] Follow the steps in Example 1 to prepare the paint.

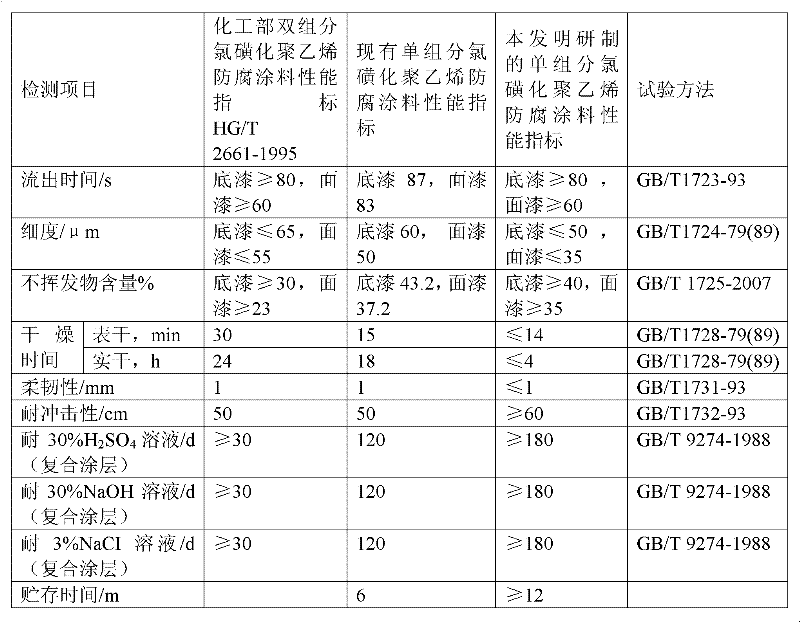

[0072] The performance index of the one-component chlorosulfonated polyethylene anticorrosive coating of the present invention and the performance comparison with similar products:

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com