Filament sizing machine condensed water recycling device

A technology of sizing machine and condensed water, which is applied in textile processing machine accessories, textile and papermaking, textile material processing and other directions, can solve problems such as waste, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

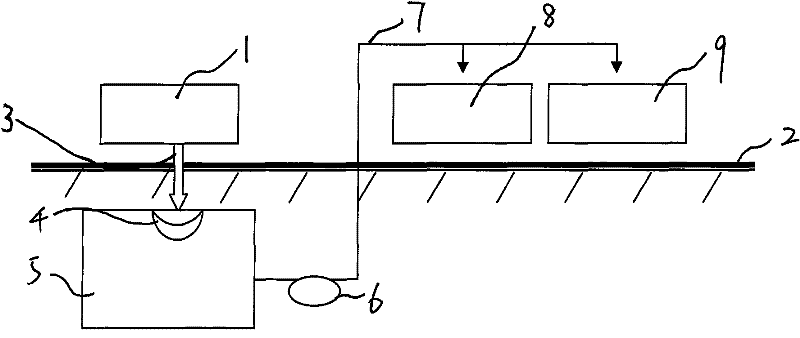

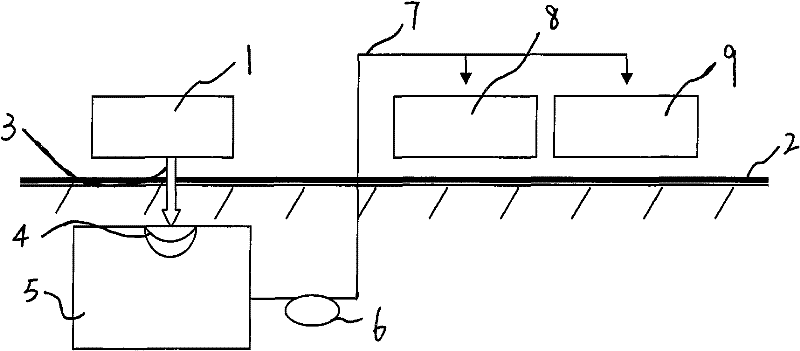

[0010] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] See attached figure 1 As shown, the condensed water recycling device of the pulping machine includes an underground water storage tank 5 connected with the outlet of the pulping machine 1 through a drain pipe 3, a water supply pipeline 7 connected with the underground water storage tank 5 by a water pump 6, and a The user end of the water supply pipe 7, the user end can be the pulping tank 8 of the pulping machine or the boiler water treatment storage tank 9. The condensed water discharged from the pulping machine automatically flows into the underground storage tank 5 through the drainage pipe 3, and then is sent to the water use place through the water pump 6 and the water supply pipe 7, so as to achieve energy saving effects such as water saving, coal saving, and electricity saving, and reduce production costs.

[0012] The underground stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com