Backscatter-based distributed fiber-optic vibration system

A distributed optical fiber and backscattering technology, applied in the direction of using wave/particle radiation, measuring devices, instruments, etc., can solve the problems of long production cycle, high price, difficult maintenance, etc., and achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

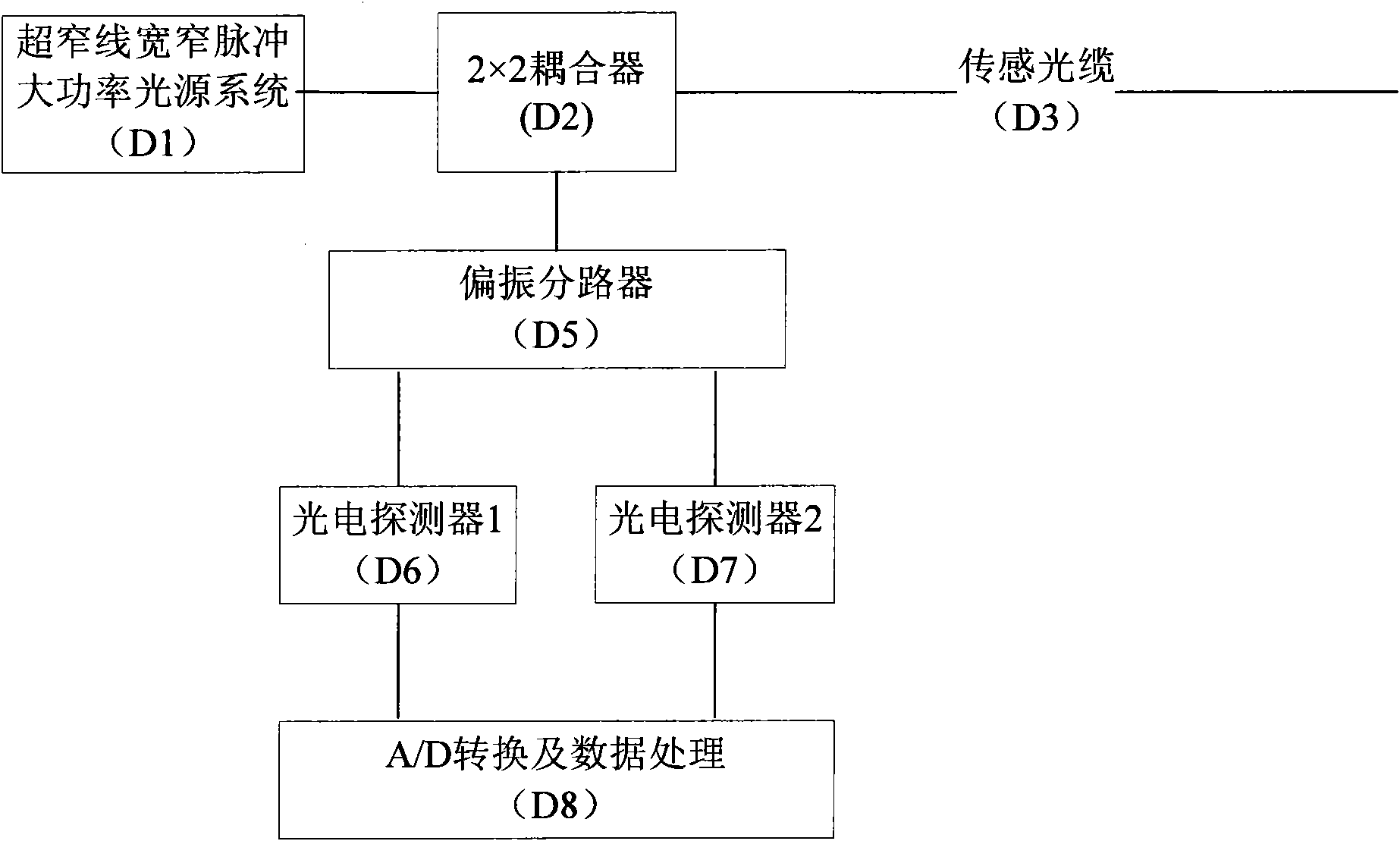

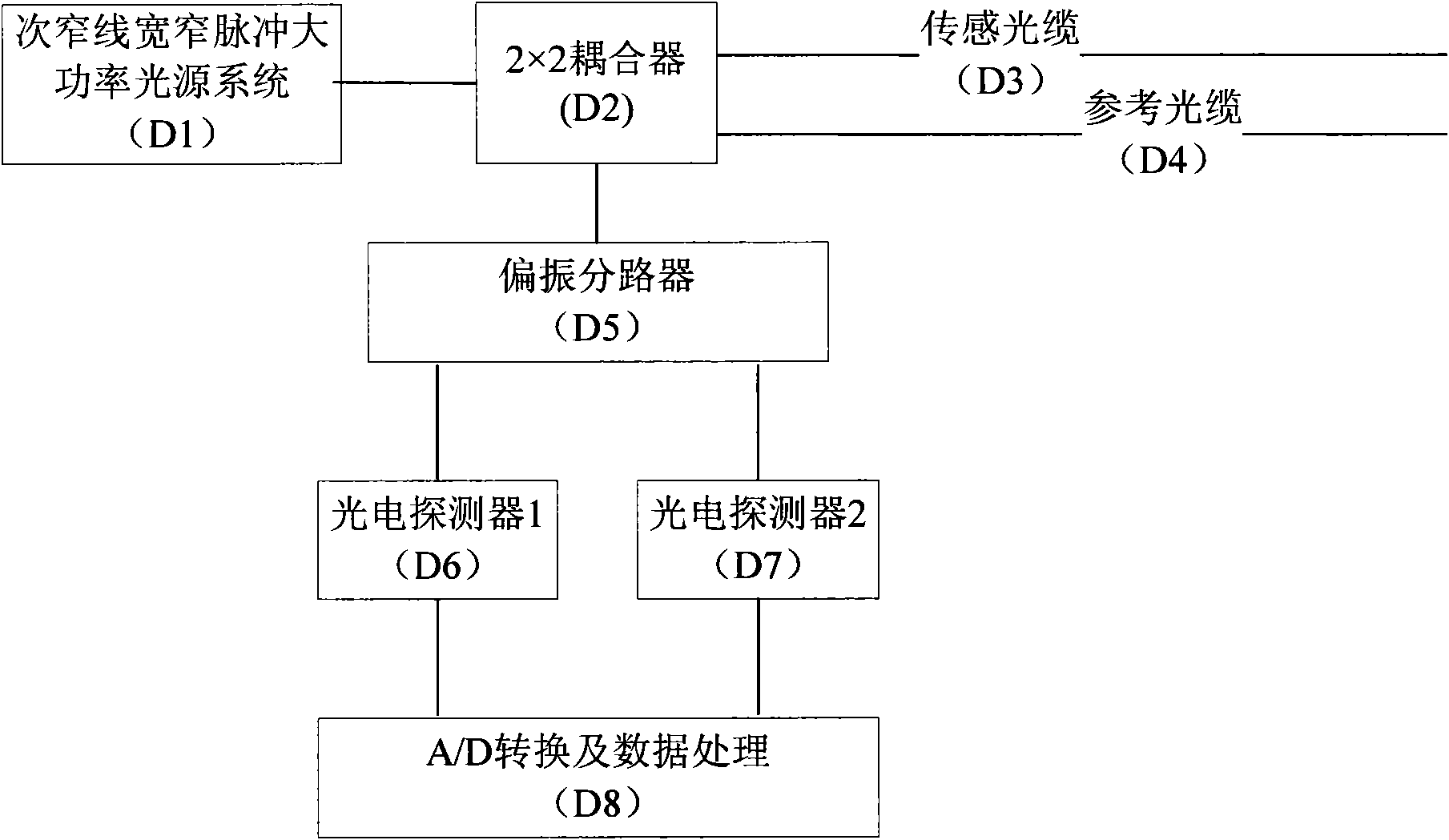

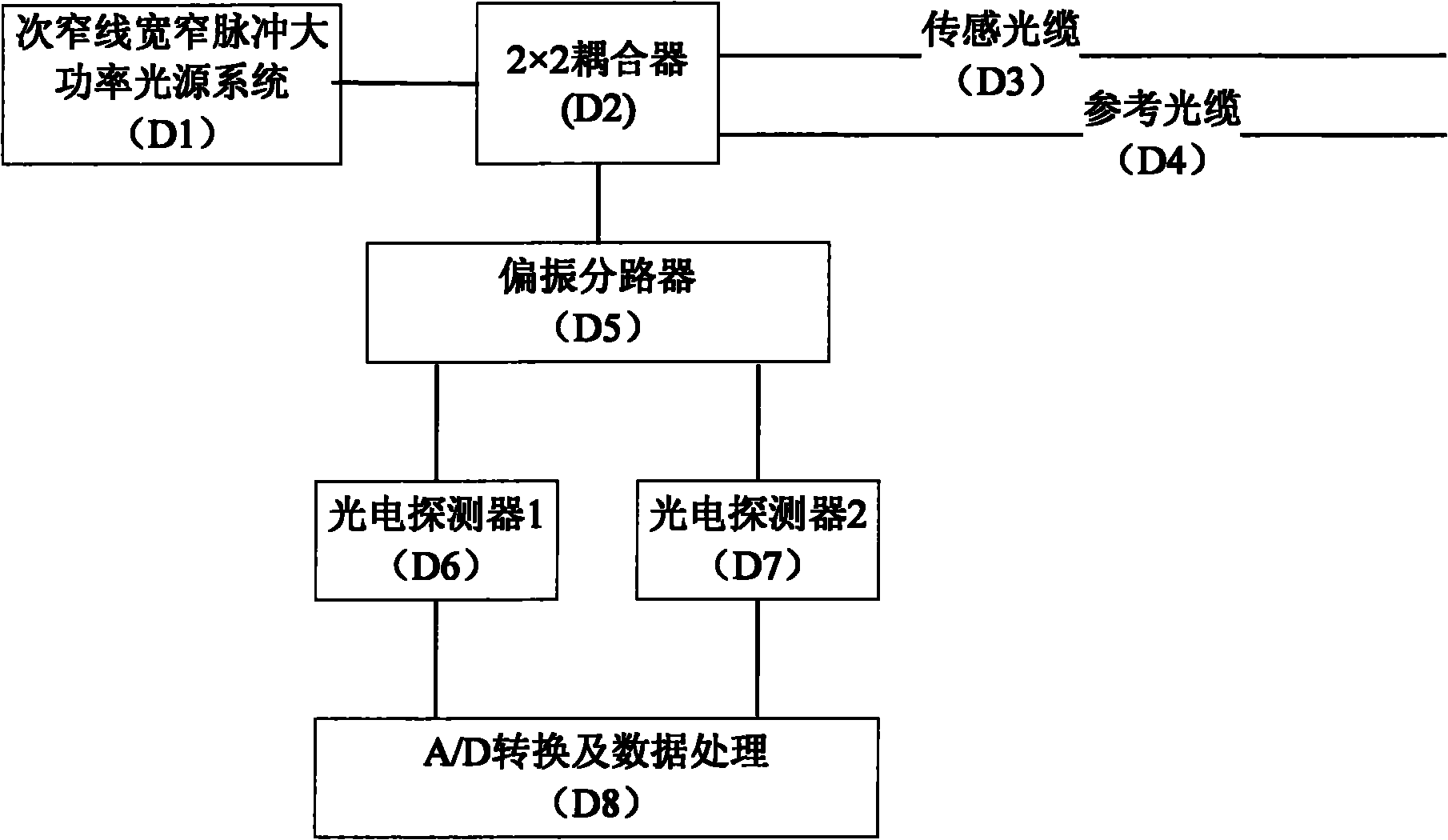

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Please refer to Fig. 2, the present invention relates to a kind of distributed optical fiber vibration system based on backscattering, it comprises sub-narrow line width high-power pulse light source (D1), 2 * 2 coupler (D2), sensing optical cable (D3) and Reference optical cable (D4), polarization splitter (D5), photodetector 1 (D6) and photodetector 2 (D7), A / D converter and data processor (D8).

[0016] The output end of the sub-narrow linewidth high-power pulse light source (D1) is connected to the first port of the primary stage of the 2×2 coupler (D2), and the secondary stage of the 2×2 coupler (D2) is respectively connected to the sensing optical cable (D3) and the reference optical cable ( D4); the other port of the main stage of the coupler is connected to the polarization splitter (D5), and the output end of the polarization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com