Navel orange surface drying monitoring method and device based on infrared thermal imaging technology

A technology of infrared thermal imaging and surface drying, which is used in measuring devices, radiation pyrometry, preparation of samples for testing, etc. The effect of uniformity and prevention of overheating damage and moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

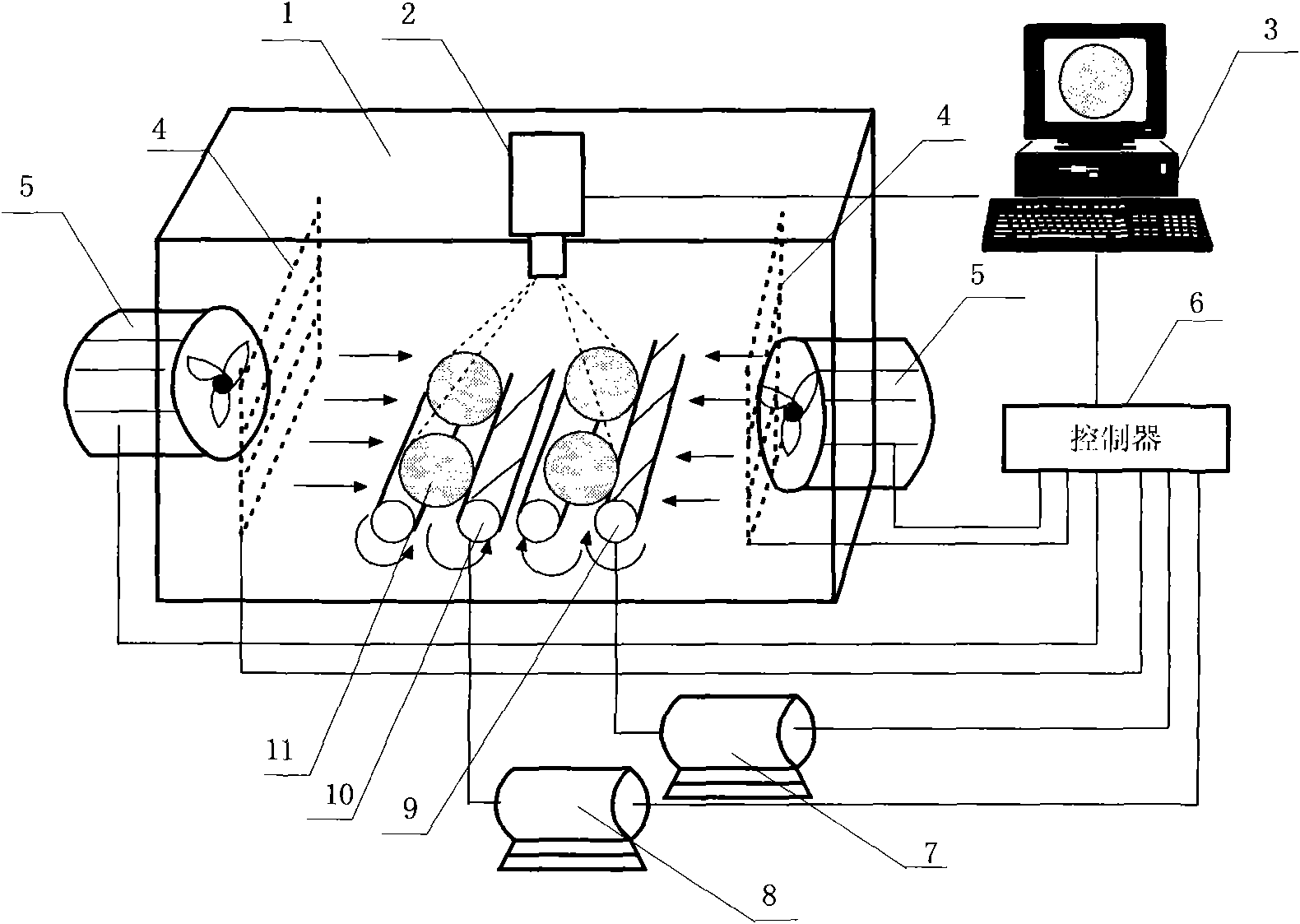

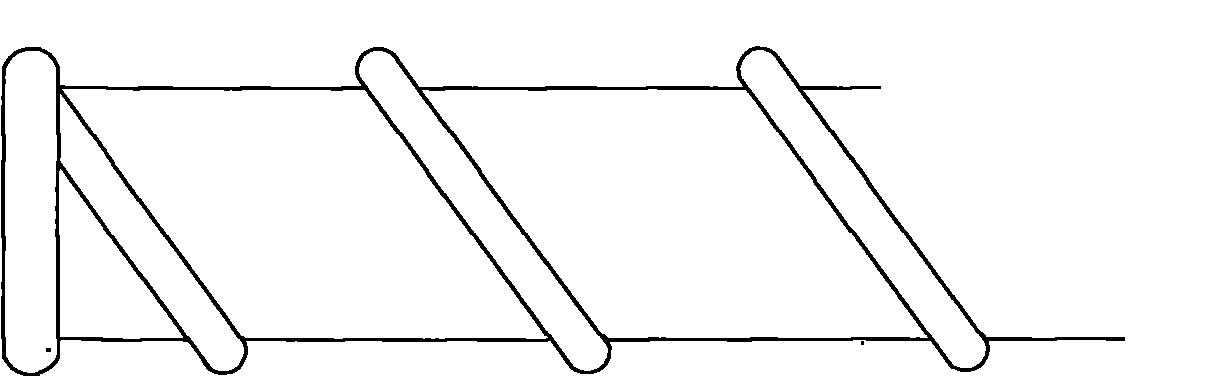

[0029] The specific embodiment of the present invention is as figure 1 As shown, the embodiment of the present invention is based on the infrared thermal imaging technology, and the on-line detection device for near-surface defects of fruits includes a drying box 1, rollers (9, 10), speed-regulating motors (7, 8), resistance wire 4, blower 5, and control Device 6, infrared camera 2, computer 3 and image processing software. Black heat-absorbing cotton is attached to the inner wall of the drying box 1 to reduce the infrared rays entering the optical lens of the infrared thermal imager and scattering mid- and long-wave bands. The steering and direction of rotation of the two pairs of rollers (9, 10) with spiral grooves are opposite, facing the left and right sides respectively. The navel orange 11 rotates around the roller axis at a certain speed by the friction force of the roller skin and the spiral groove, and at the same time The direction of rotation of the spiral groove r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com