Recovery-type harmonic suppression system at DC side of multi-pulse rectification system and method

A multi-pulse rectification and harmonic suppression technology, which is applied to output power conversion devices, electrical components, etc., can solve the problems of increased volume and capacity, and achieve the effects of increased volume, large system capacity and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

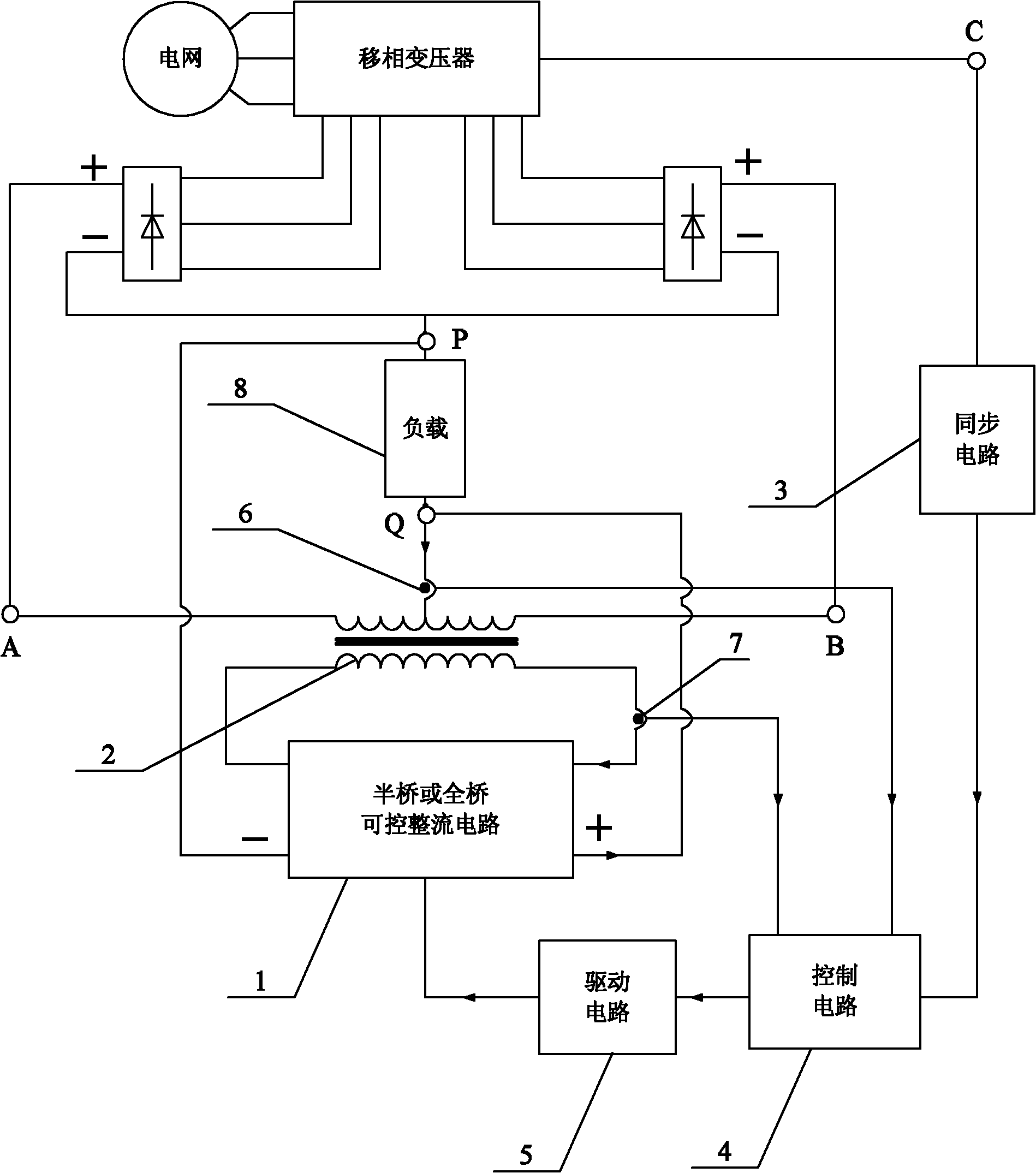

[0024] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the DC side recovery type harmonic suppression system of the multi-pulse rectification system described in this embodiment, it includes a half-bridge or full-bridge controllable rectification circuit 1, a balance reactor with a secondary side 2, a synchronous circuit 3. Control circuit 4, drive circuit 5, load loop current sensor 6 and reactor secondary current sensor 7,

[0025] The primary side of the balanced reactor 2 with the secondary side is connected between the power input terminal A and the power input terminal B of the harmonic suppression system, and the middle tap of the primary side of the balanced reactor 2 with the secondary side is connected to the harmonic The positive output terminal Q of the load power supply of the suppression system, the secondary side of the balance reactor 2 with the secondary side is connected to the AC input terminal of the half-bridg...

specific Embodiment approach 2

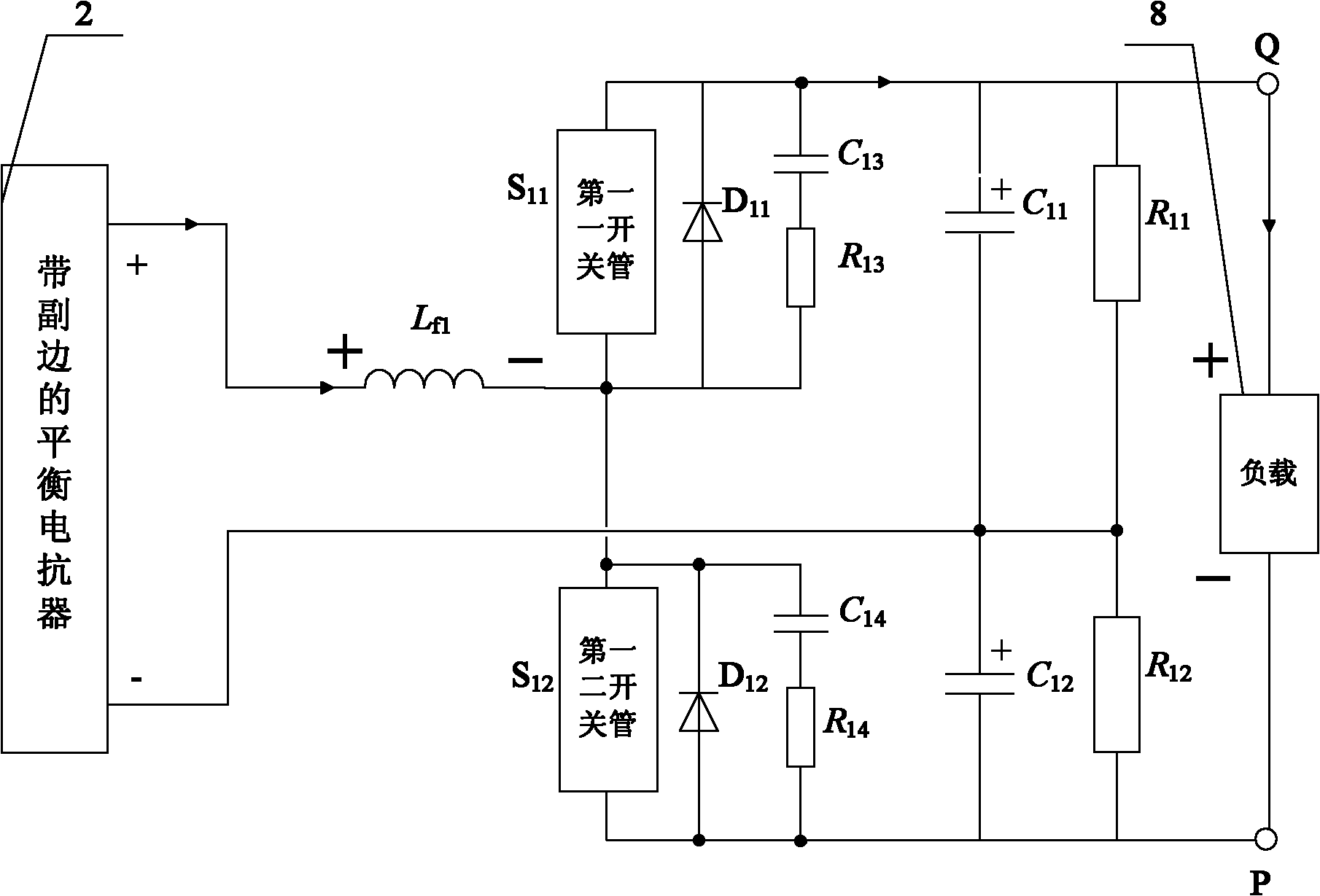

[0032] Specific implementation mode two: the following combination figure 1 and figure 2This embodiment is described. This embodiment is a further limitation of Embodiment 1. The half-bridge or full-bridge controllable rectification circuit 1 is a half-bridge controllable rectification circuit, and the half-bridge controllable rectification circuit is composed of a first inductor L f1 , the first switch tube S 11 , the first diode D 11 , the first and third capacitors C 13 , the first and third resistors R 13 , the first capacitor C 11 , the first resistor R 11 , the first and second switching tube S 12 , the first and second diode D 12 , the first four capacitance C 14 , the first and fourth resistors R 14 , the first and second capacitance C 12 and the first two resistors R 12 composition,

[0033] The positive pole of the secondary side of the balance reactor 2 with the secondary side is connected to the first inductance L f1 At one end, the first inductor L ...

specific Embodiment approach 3

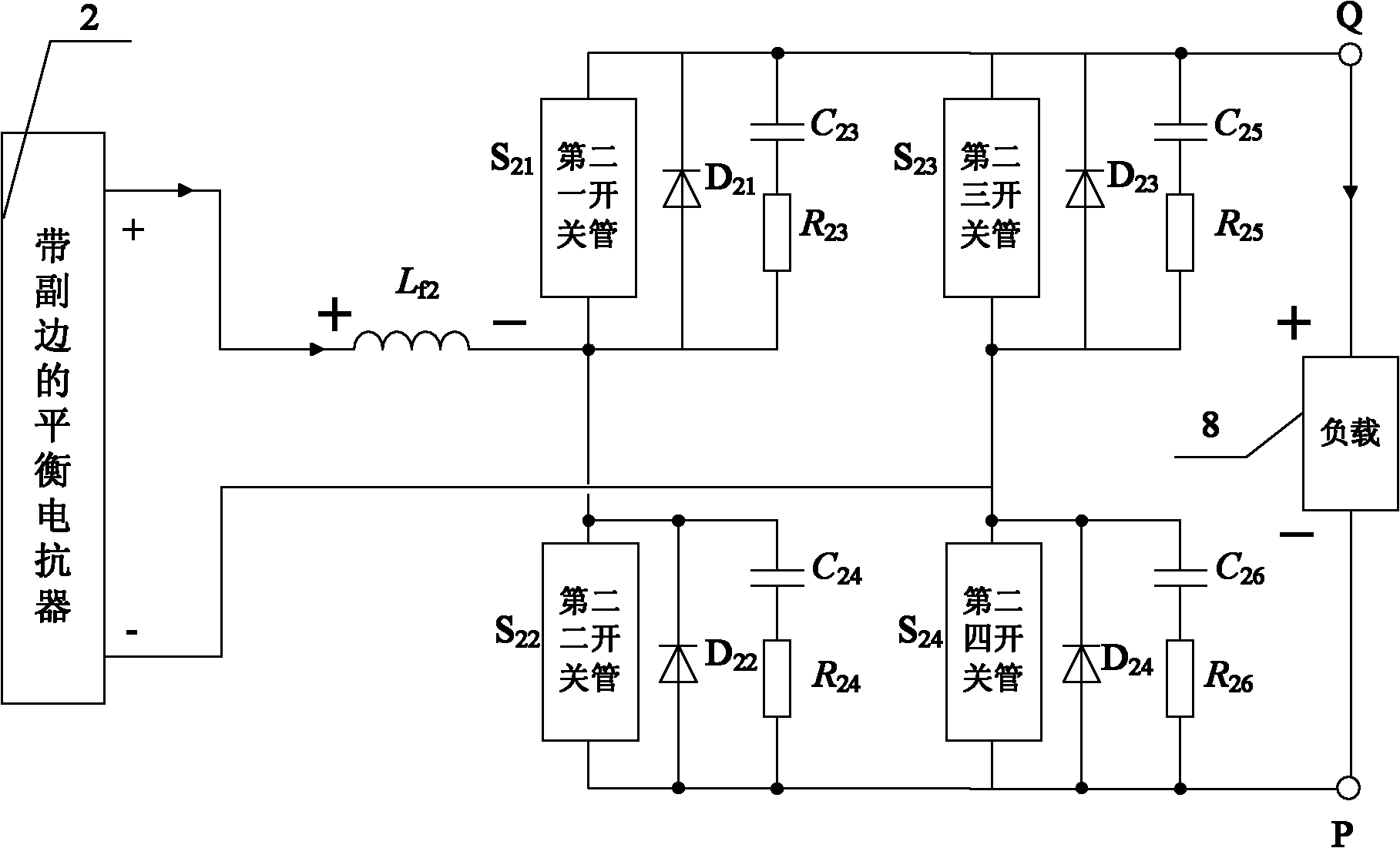

[0039] Specific implementation mode three: the following combination figure 1 with image 3 Describe this embodiment, this embodiment is a further limitation of Embodiment 1, the half-bridge or full-bridge controllable rectification circuit 1 is a full-bridge controllable rectification circuit, and the full-bridge controllable rectification circuit is composed of a second inductor L f2 , the second switch tube S 21 , the second one diode D 21 , the second and third capacitance C 23 , the second and third resistors R 23 , the second and third switching tubes S 23 , the second and third diodes D 23 , the second five capacitance C 25 , the second fifth resistance R 25 , the second switch tube S 22 , the second two diode D 22 , the second and fourth capacitance C 24 , the second and fourth resistance R 24 , the second and fourth switching tubes S 24 , the second and fourth diode D 24 , the second six capacitance C 26 and the second six resistors R 26 composition,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com