Cone crusher

A cone crusher and moving cone technology, applied in the field of mining machinery and equipment, can solve problems such as difficulty in increasing the rotational speed of the eccentric bushing, accelerated partial wear of the eccentric bushing, locking of the main shaft and the eccentric bushing, etc., so as to improve operating efficiency and output, reduction of frictional resistance, and enhancement of lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

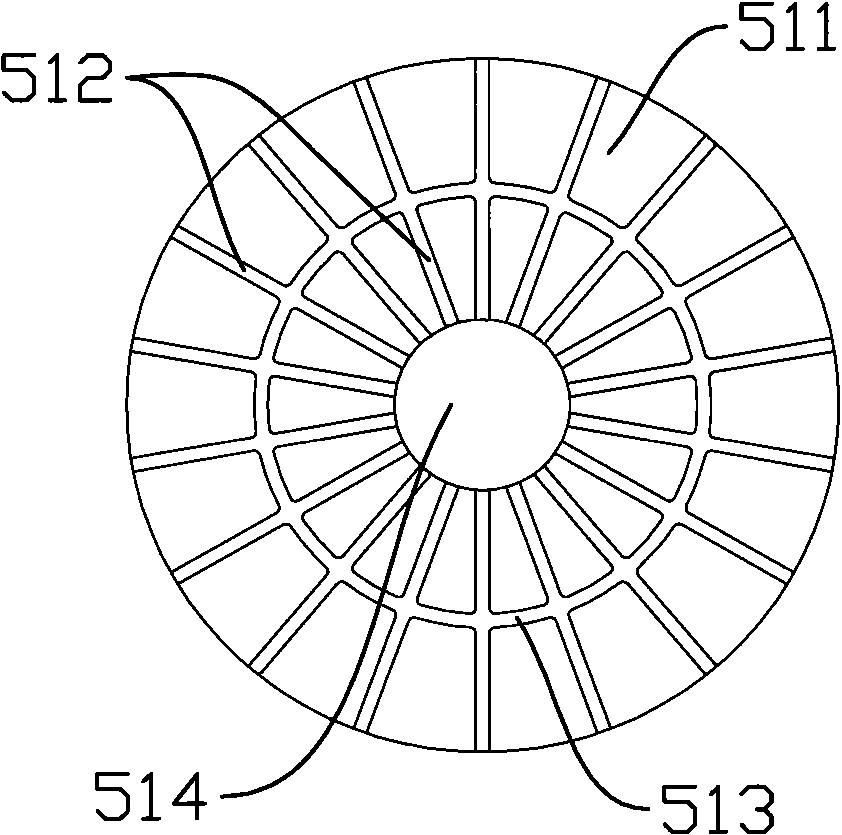

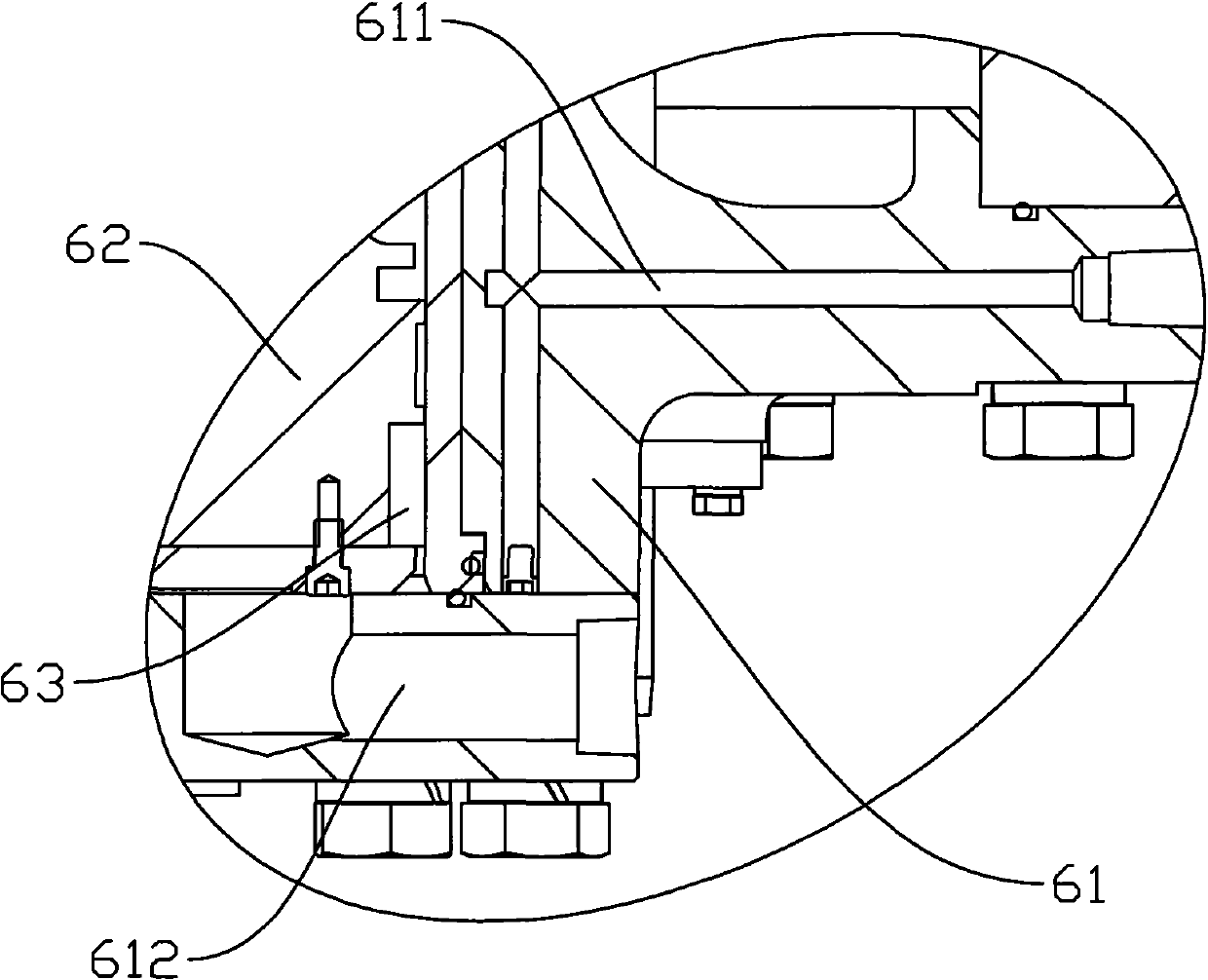

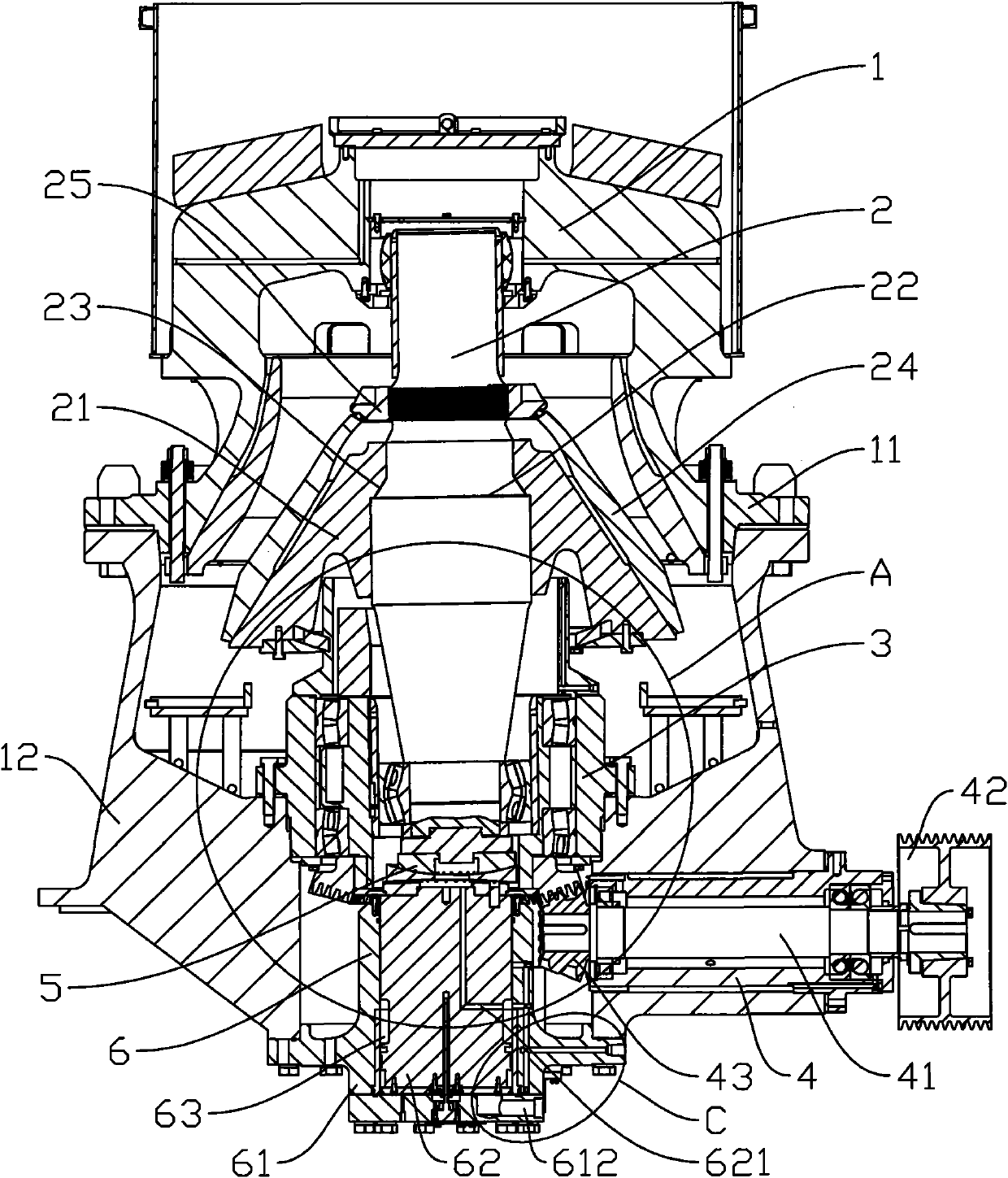

[0021] like Figures 1 to 6 Shown is a schematic structural diagram of an embodiment of the present invention, a cone crusher, including a frame 1 and a movable cone main shaft 2 arranged in the frame, the frame includes an upper frame 11 and a lower frame 12, and the movable cone main shaft. The lower end is provided with an eccentric mechanism 3, and the eccentric mechanism is connected with the transmission assembly 4. The transmission assembly includes a transmission main shaft 41 arranged on the lower frame. The inner end of the transmission main shaft is provided with a bevel gear 43 to be linked with the eccentric mechanism. It extends out of the lower frame and is provided with a pulley 42 for interlocking with the motor. Below the eccentric mechanism is a support assembly 5 for supporting the main shaft of the moving cone. The lower end of the moving cone passes through the eccentric mechanism and is pressed on the support assembly, the moving cone main shaft is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com