Combined down-the-hole hammer and construction method thereof

A combined down-the-hole hammer and construction method technology, which is applied to drilling equipment and methods, earthwork drilling, percussion drilling, etc., can solve the problems of inconvenient maintenance and repair, lack of adjustment function, and difficult manufacturing, etc., to achieve Improve drilling efficiency, effectively use energy, and simplify the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

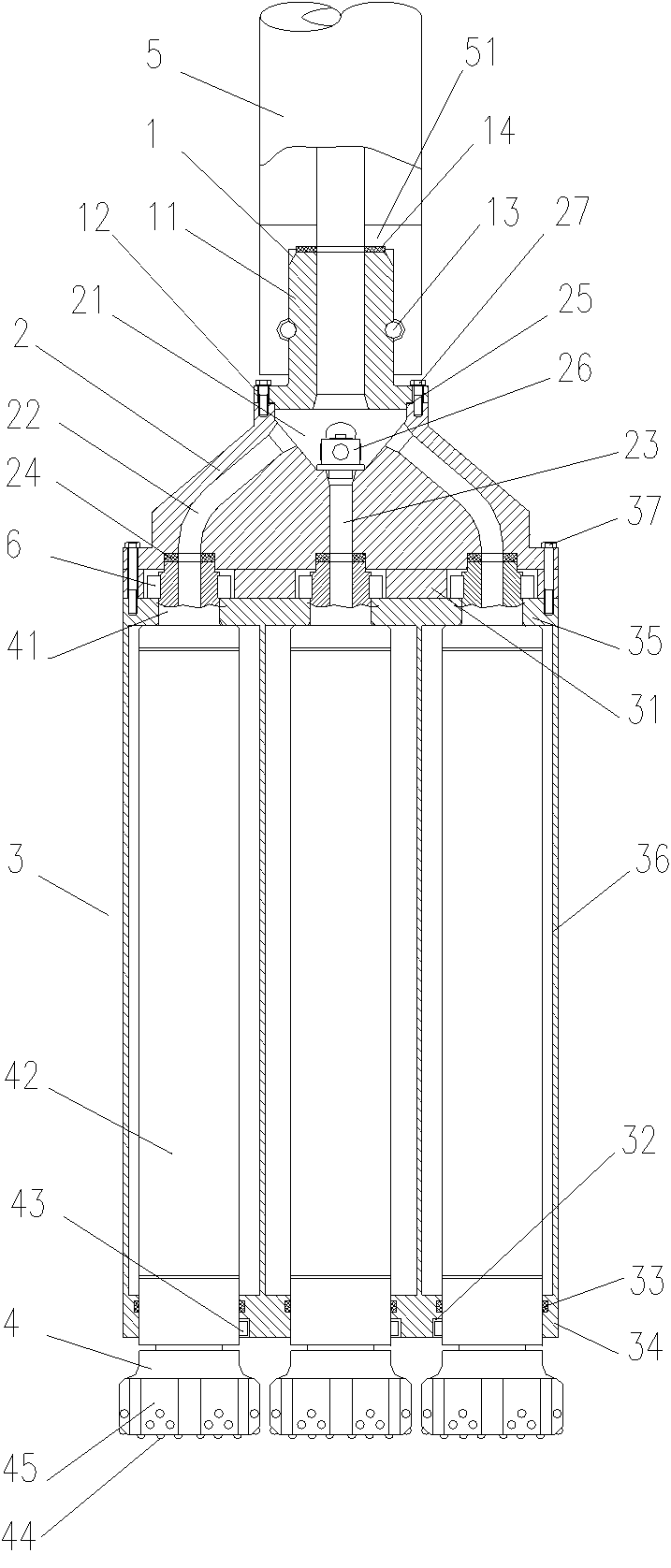

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

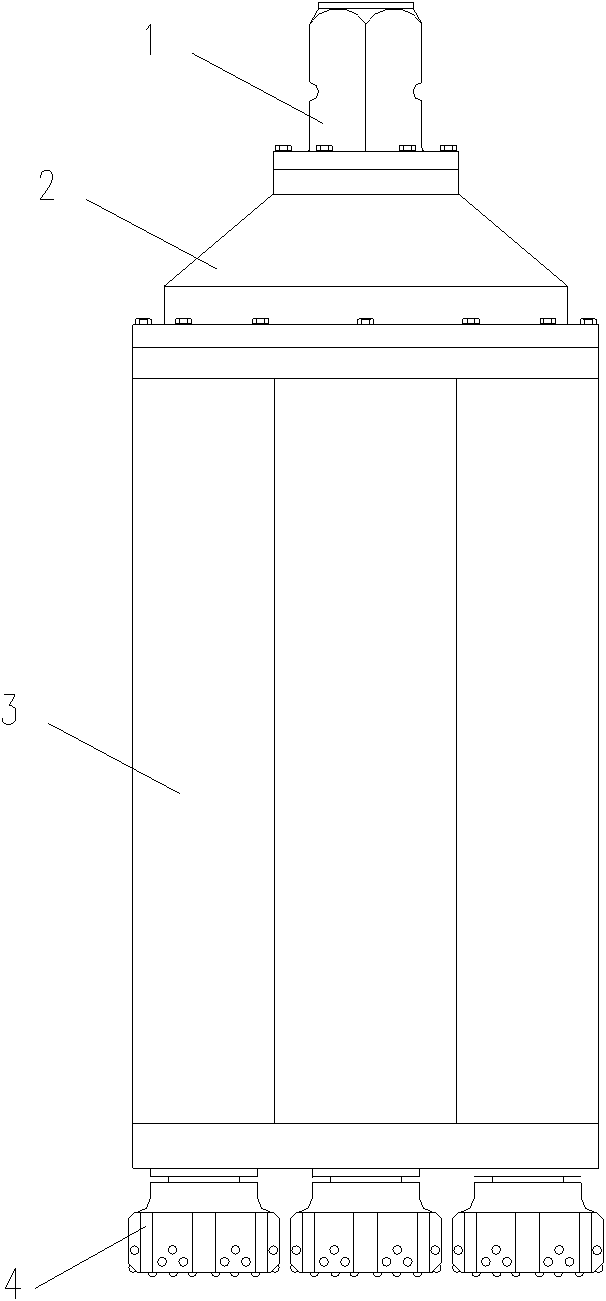

[0043] refer to figure 1 , figure 2 , image 3 and Figure 4 One end of the gas distribution device 2 is connected to the bracket body 3, and the other end is connected to the coupler 1, and a plurality of small-diameter impactors 4 are installed on the bracket body 3.

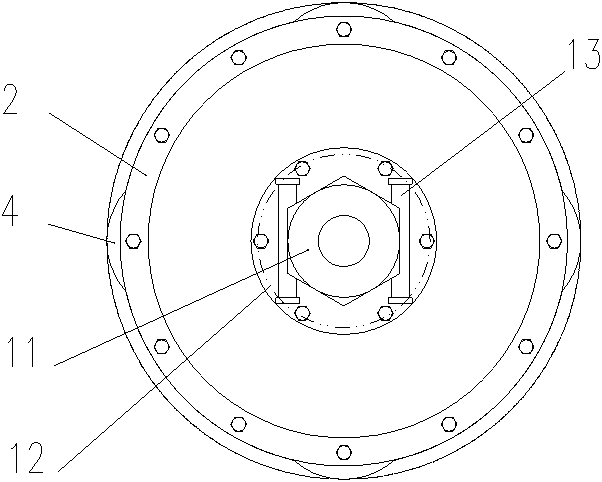

[0044] The coupling 1 is mainly composed of a hexagonal cylindrical structure 11, a flange 12, a pin shaft 13, and a gasket 14; the hexagonal cylindrical structure 11 is connected to the inner hexagonal joint of the drill pipe 5 by means of two pin shafts 13 and gaskets 14 51 are plugged and fixed.

[0045] The gas distribution device 2 is mainly composed of a gas collection chamber 21, a large curvature gas path structure 22, a straight-through structure 23, a first sealing ring 24, and a second sealing ring 25; the bracket body 3 is composed of a transition plate 31 with holes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com