High-efficiency mixed flow compressor impeller

A compressor and mixed flow technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as affecting the efficiency of compressors, and achieve the effects of simple structure, high structural reliability, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

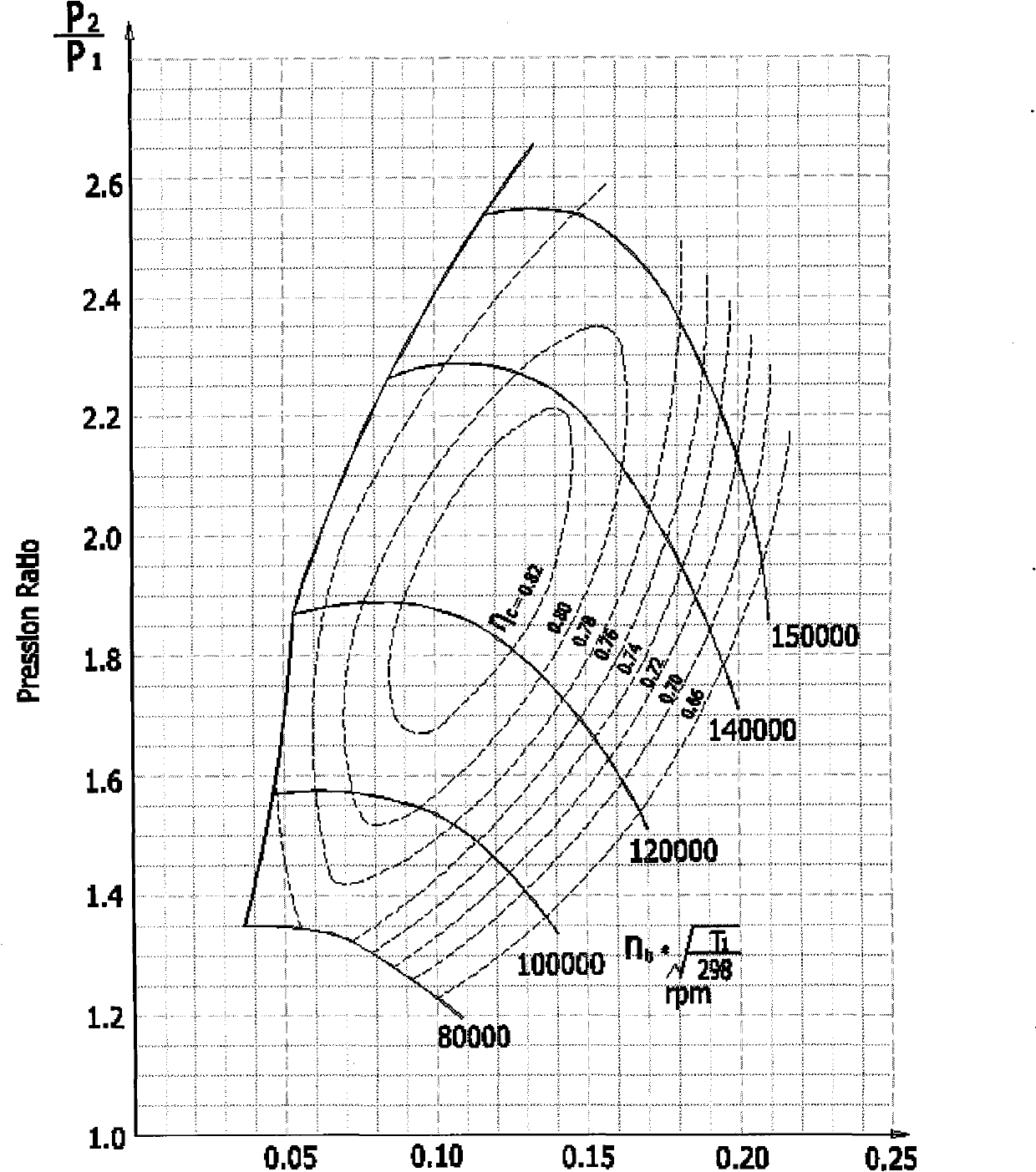

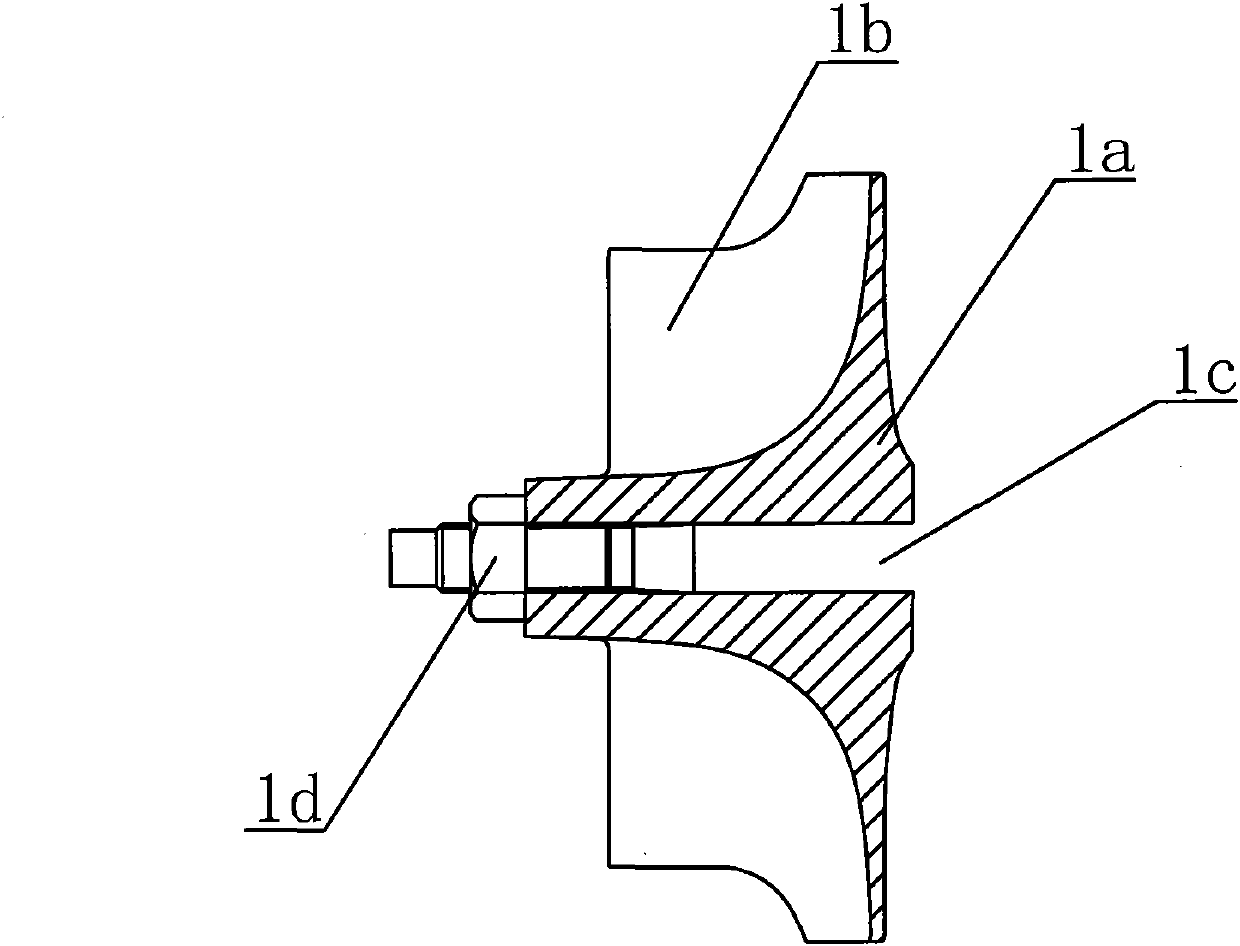

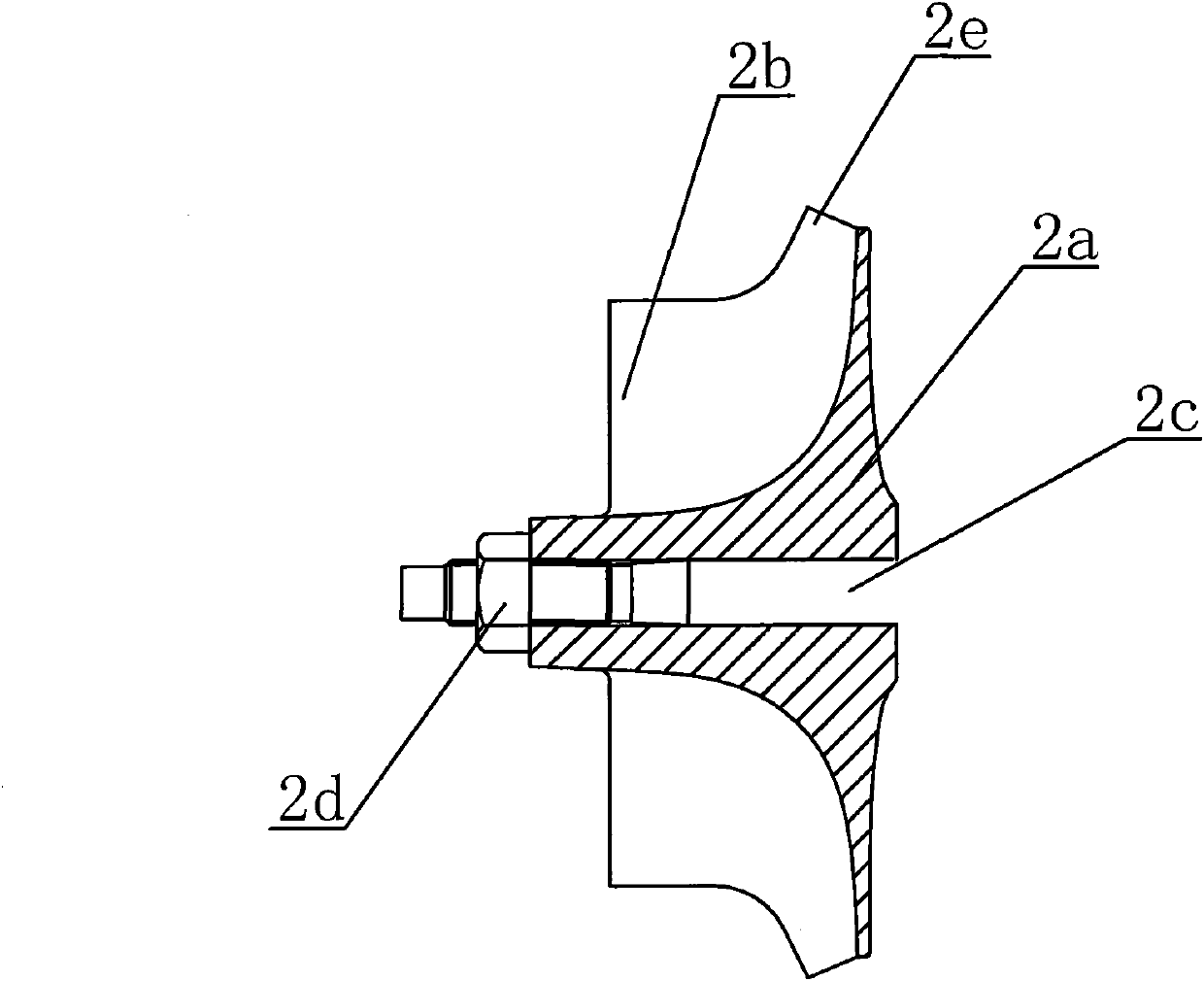

[0013] Please refer to figure 2 and image 3 as shown, figure 2 It is a sectional view of the high-efficiency mixed-flow compressor impeller of the present invention, image 3 For assembling the compressor test characteristic chart of the present invention.

[0014] In this embodiment, a high-efficiency mixed-flow compressor impeller includes a hub body 2a and a plurality of blades 2b combined with the hub body 2a. The blades 2b are mixed-flow blades, and a flow is formed between two adjacent blades 2b. and the distance from the outer edge of the blade 2b to the center of the hub body 2a is greater than the radius of the hub body 2a, so that the outer edge of the blade 2b forms an auxiliary mixing part 2e, and the hub body 2a is provided with a central hole through which The entire mixed-flow impeller is fixed on the rotor shaft 2c with a lock nut 2d, the mixed-flow blade 2b of the high-efficiency mixed-flow compressor impeller adopts a mixed-flow blade, and the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com