Device and method for accurately sampling plating solution in plating pot in hot plating production line

A sampling device and production line technology, applied in the direction of sampling devices, etc., can solve the problems of poor operating safety, low sampling efficiency, insufficient research, etc., and achieve the effects of avoiding manual sampling errors, enhancing product applicability, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

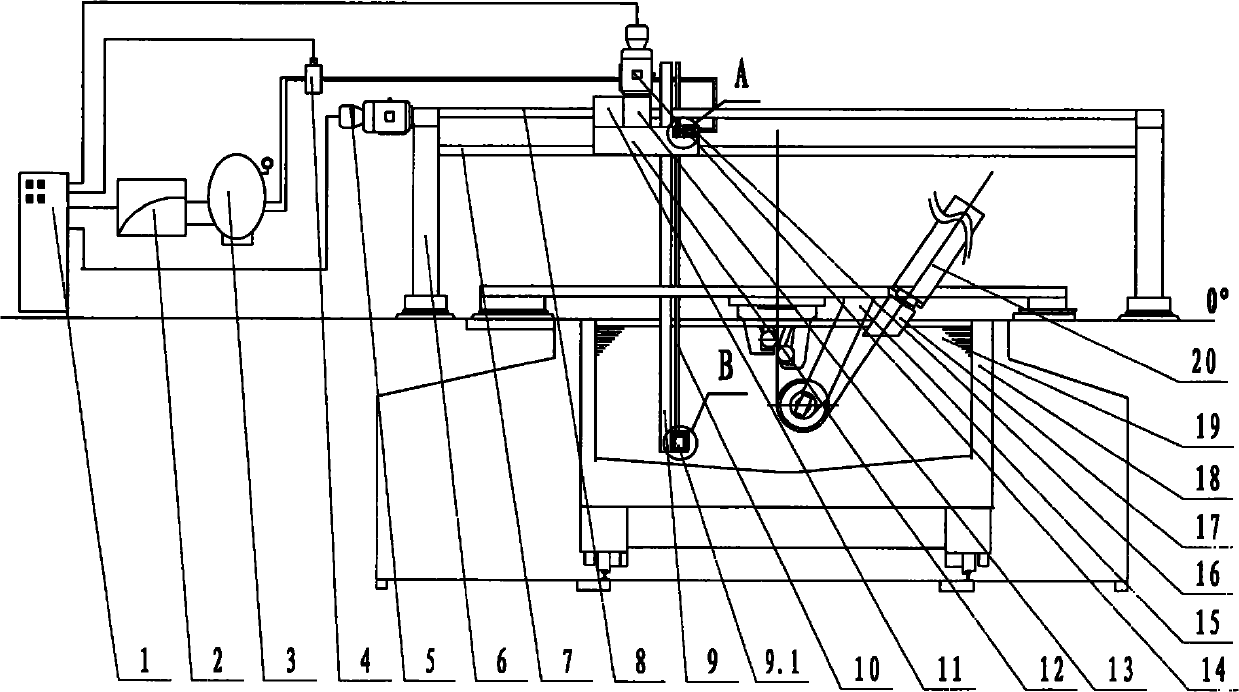

[0028] An embodiment of the present invention will be described below with reference to the accompanying drawings.

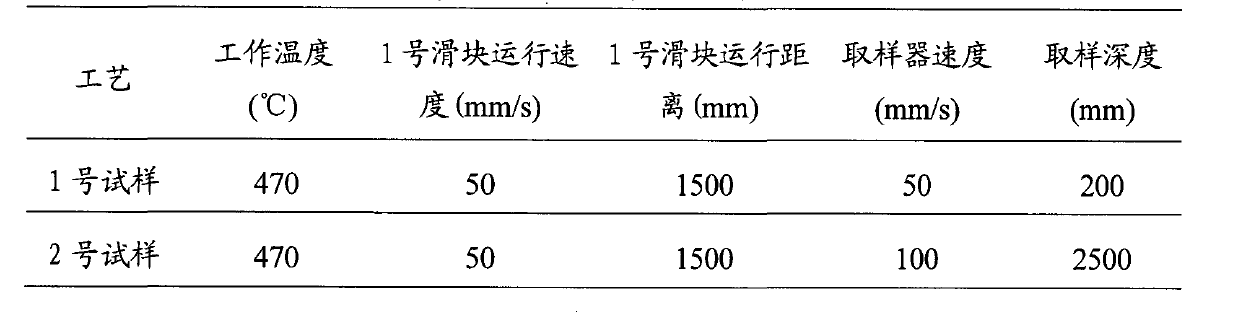

[0029] The embodiment of the present invention adopts the device and the method of the present invention to sample and study the plating solution of the hot-dip production line. The production line selected for the experiment is a hot-dip galvanizing production line of a large domestic iron and steel enterprise. The composition of zinc liquid is 0.2% aluminum, trace Fe, and the rest is pure zinc. The steel strip is a high-strength IF steel for automobile plates produced by a domestic steel mill. Its chemical composition is shown in Table 1. The thickness of the test steel strip is 0.4 mm.

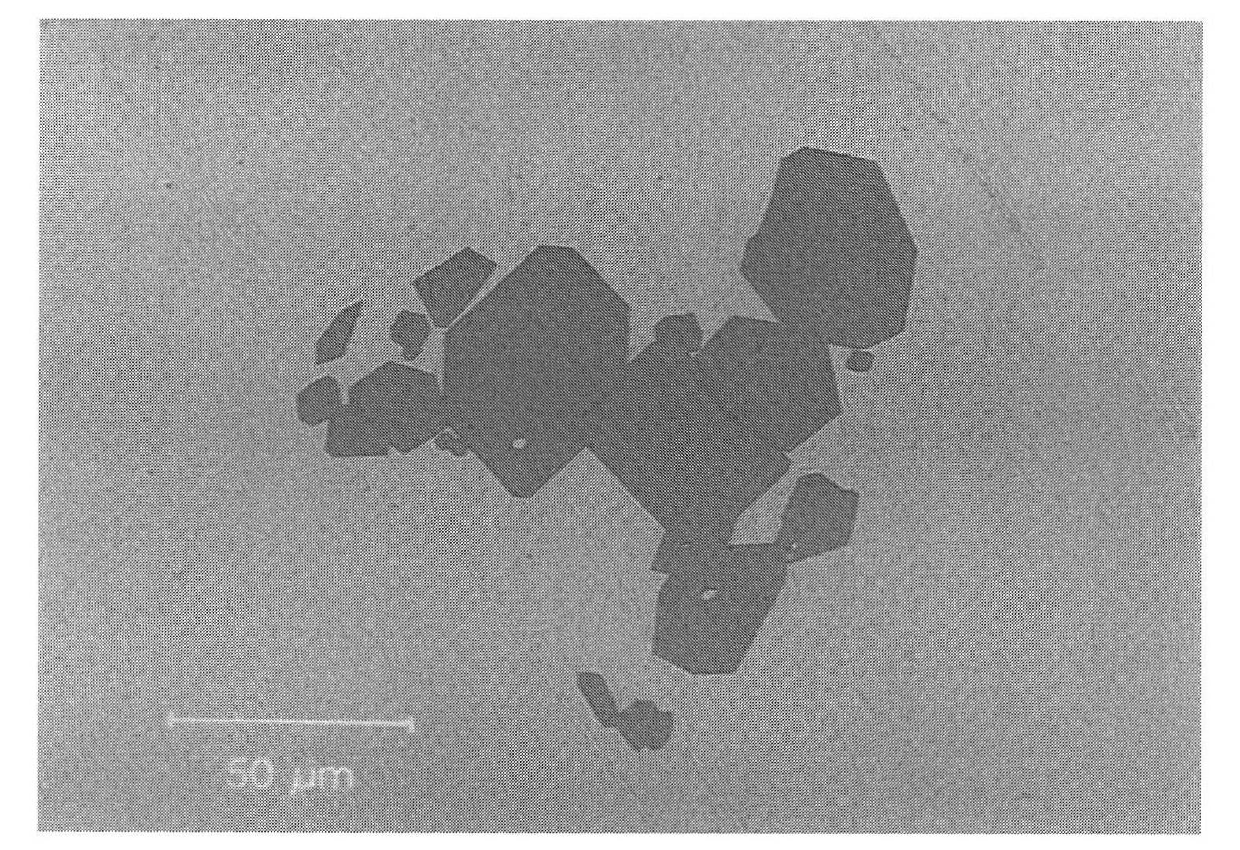

[0030] Bath sampling study. The sample was corroded with 0.75% nitric acid alcohol, and the interface of the sample was scanned with a scanning electron microscope with a JSM-6480 target voltage of 20KV from Hitachi, Japan. image 3 and Figure 4 shown.

[0031] Depend o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com