Tissue paper for domestic use

A technology for household and thin paper, which can be applied to household utensils, thin paper/absorbent paper, paper, etc. It can solve the problems of hard touch, thinner thickness, and stiffness, etc., and achieve the effect of excellent strength and soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

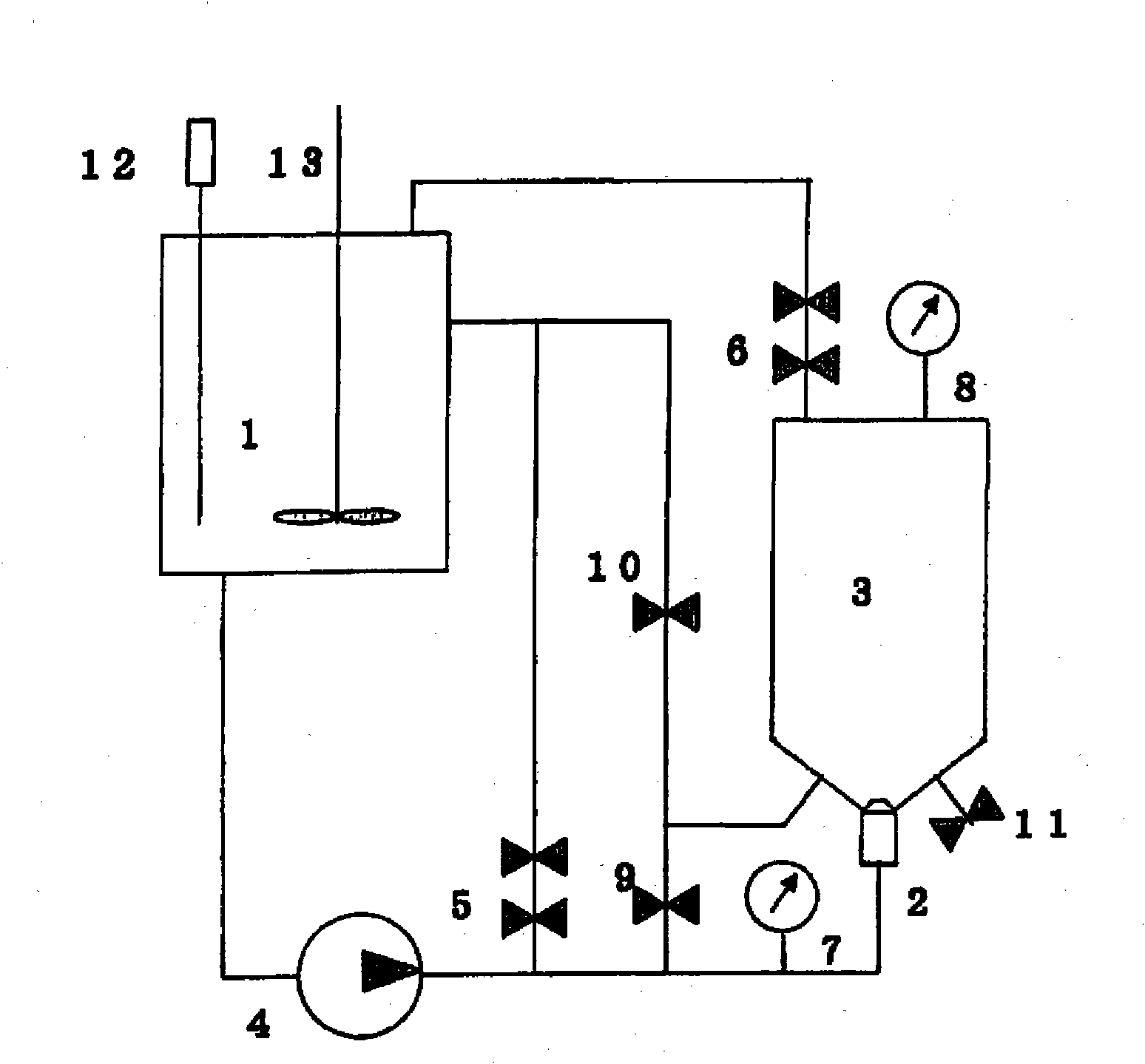

[0102] The raw materials of the upper layer and the lower layer among the three layers were prepared as follows. Pulp sheets of hardwood bleached kraft pulp are dissociated in a low-consistency pulper and adjusted to an arbitrary consistency before use figure 1 In the cavitation jet treatment device shown (nozzle diameter 1.5 mm), the pressure of the spray liquid (pressure on the upstream side of the nozzle) is set to 8 MPa (gauge pressure, jet flow velocity 80 m / s), and the water in the container to be sprayed The pressure (pressure on the downstream side of the nozzle) was set to 0.4 MPa (gauge pressure), and a one-shot process was performed. Among them, a pulp suspension with a concentration of 3% by weight was used as the spray liquid, and the pulp suspension (with a concentration of 3% by weight) in the container was cavitated to a Canadian standard freeness of 435 mL to obtain a raw material A. Tissue papers were produced from stock A and middle stock B (pulp sheets of ...

Embodiment 2

[0109] The raw materials in the upper and lower layers were treated in the same manner as in Example 1, and the Canadian standard freeness was set to 420 mL to obtain the raw material D. Tissue paper was produced by adding 0.1% of wet paper strength enhancer (relative to pulp absolute dry weight) to raw material D and middle layer raw material B. The grammage of thin paper after papermaking is 13.0g / m 2 way to adjust.

Embodiment 3

[0116] The raw materials of the upper and lower layers are treated with a cavitation jet flow processing device (nozzle diameter 1.5mm), and the pressure of the spray liquid (pressure on the upstream side of the nozzle) is set to 8MPa (gauge pressure, jet flow velocity 80m / s), and the The pressure in the sprayed container (pressure on the downstream side of the nozzle) was set to 0.4MPa (gauge pressure), and except that two passes were performed, the same process was carried out as in Example 1, and the Canadian standard freeness was set to 390mL , obtained raw material F. Tissue paper was produced by adding 0.1% of wet paper strength enhancer (relative to pulp absolute dry weight) to raw material F and middle layer raw material B. The grammage of thin paper after papermaking is 15.1g / m 2 way to adjust.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| base weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com