Automatic line-grasping control method of deicing robot in high-voltage transmission line

A high-voltage transmission line and control method technology, applied in the direction of manipulators, electrical components, manufacturing tools, etc., can solve problems such as difficulty in ensuring control accuracy, complex algorithms, and inability to meet the real-time requirements of engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The technical scheme and working process of the present invention will be further described below with specific embodiments in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

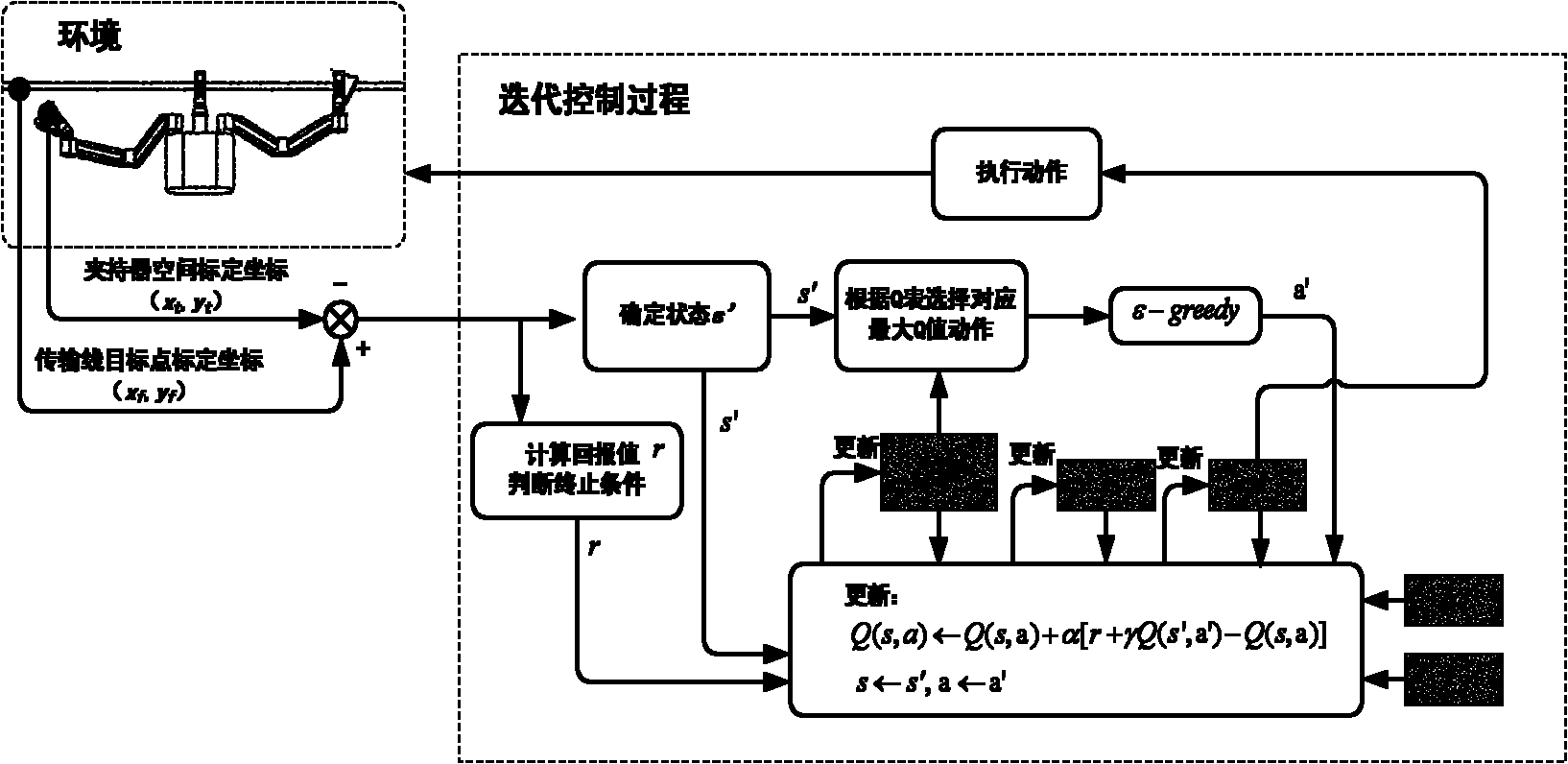

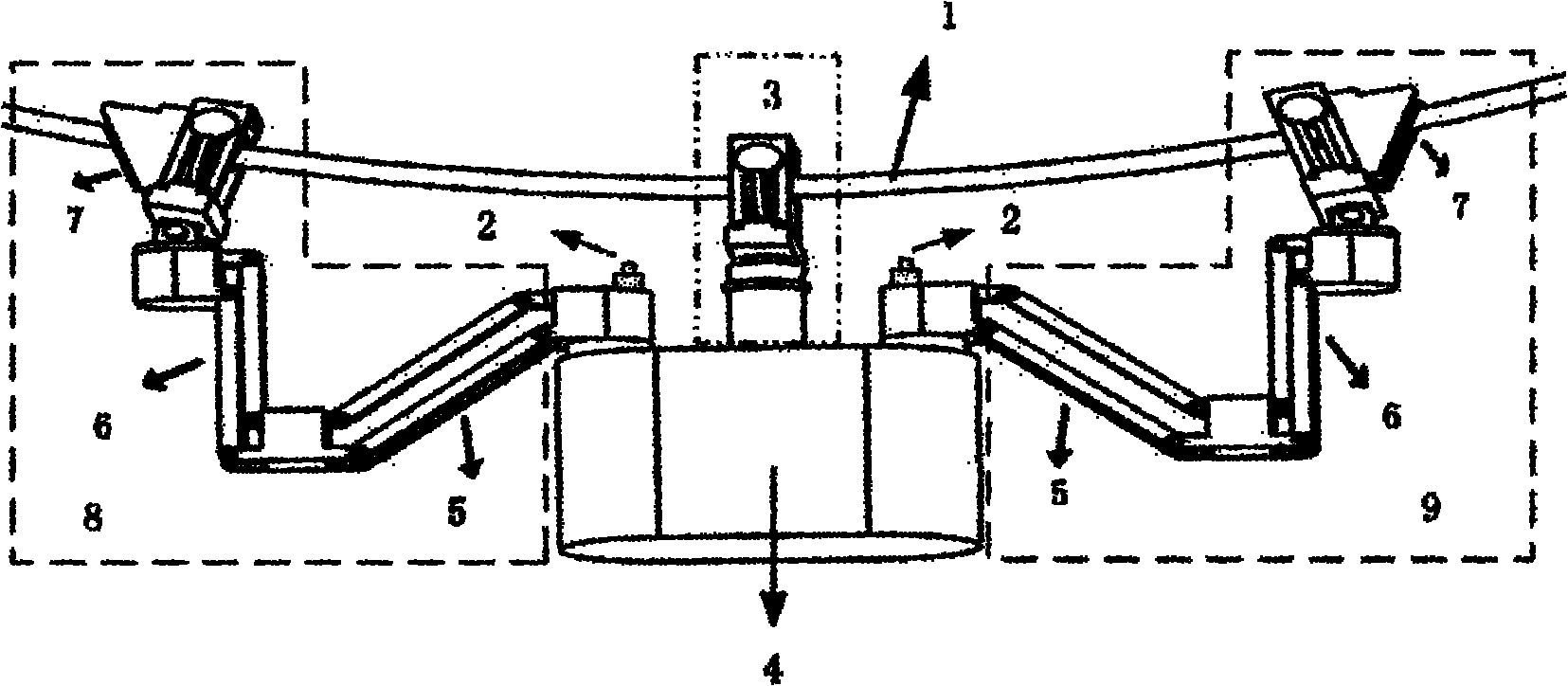

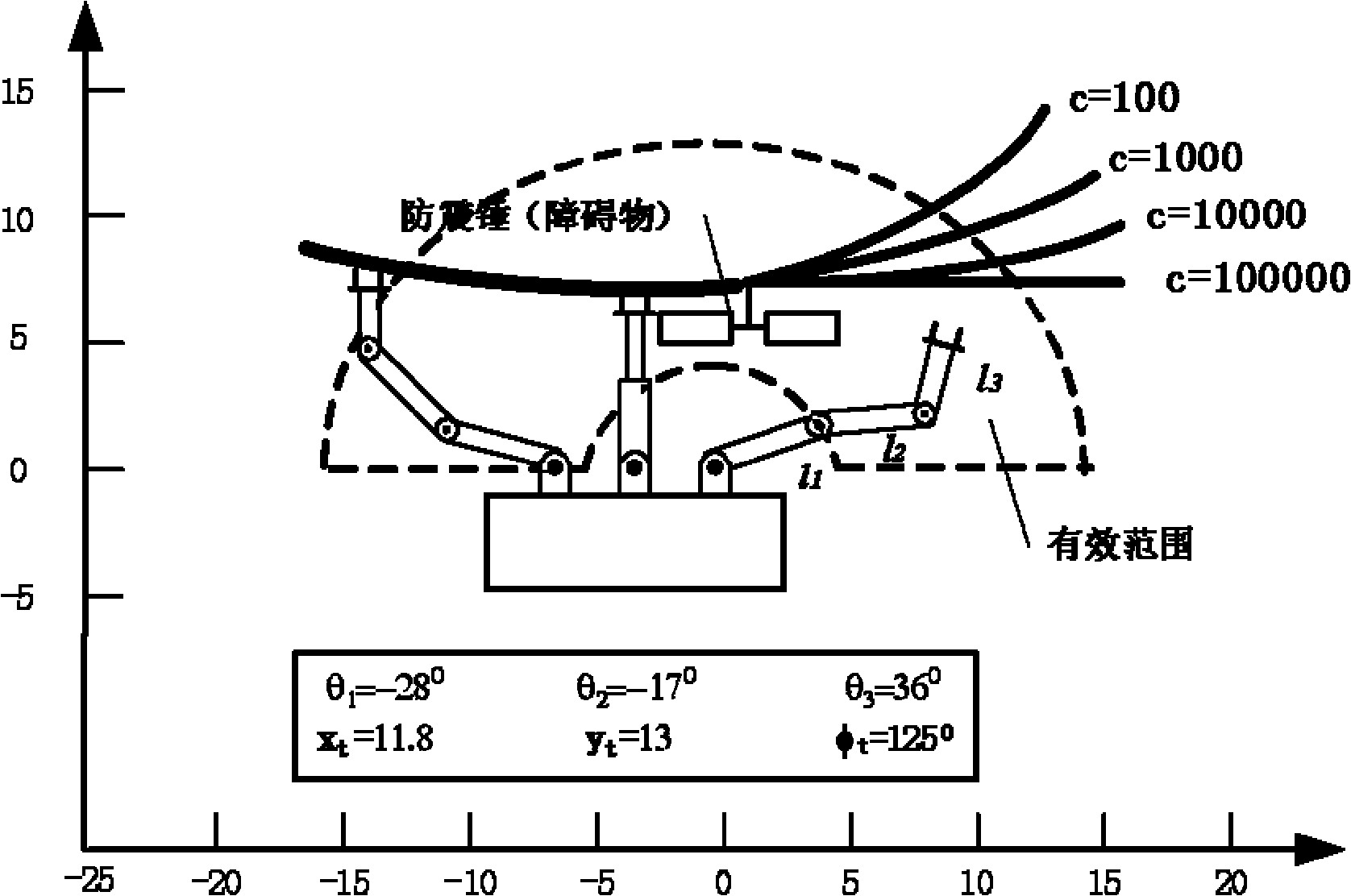

[0090] Taking a deicing robot with three mechanical arms as the control object, combined with the kinematics theory of the three-joint arm, to enhance the learning of the SARSA algorithm (the five-tuple (s, a, r, s′ used in each iteration of the algorithm) , a'), so the algorithm is named as the SARSA algorithm) to control the arm to catch the line. According to the characteristic that the transmission line is a flexible arc, the corresponding reward function is designed and its validity is verified. control process such as figure 1 , characterized in that the steps are:

[0091] 1. Establish an enhanced learning system.

[0092] The environment in which the deicing robot grasps the line can be described as a finite-state d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com