Internal heating die sleeve

A technology of internal heating and mold sleeves, which is applied in the direction of ceramic forming machines and manufacturing tools, can solve the problems of damage to the outer surface quality of carbon blocks, the inability to replace thermal insulation materials, and the reduction of thermal insulation performance, so as to improve the quality of the outer surface and simplify the structure , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

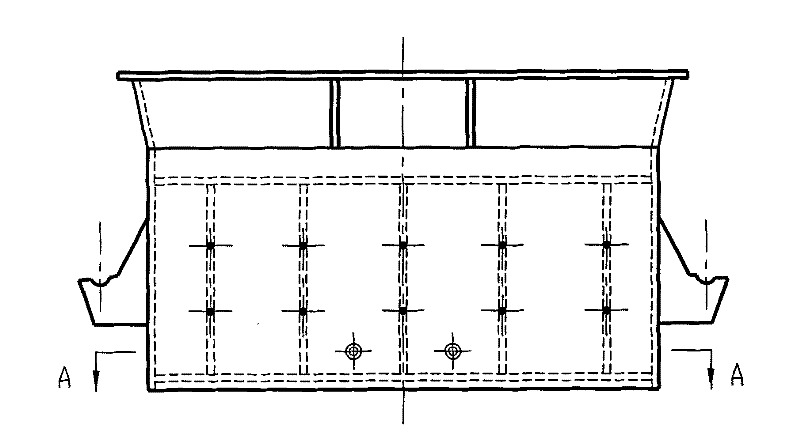

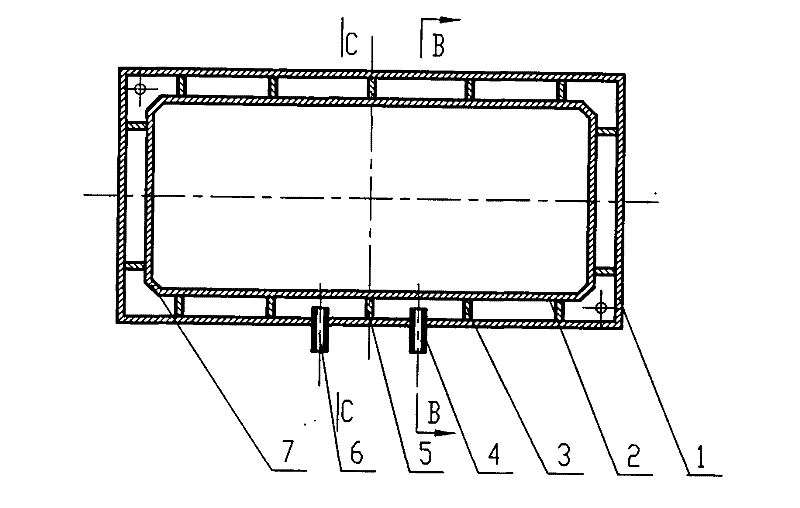

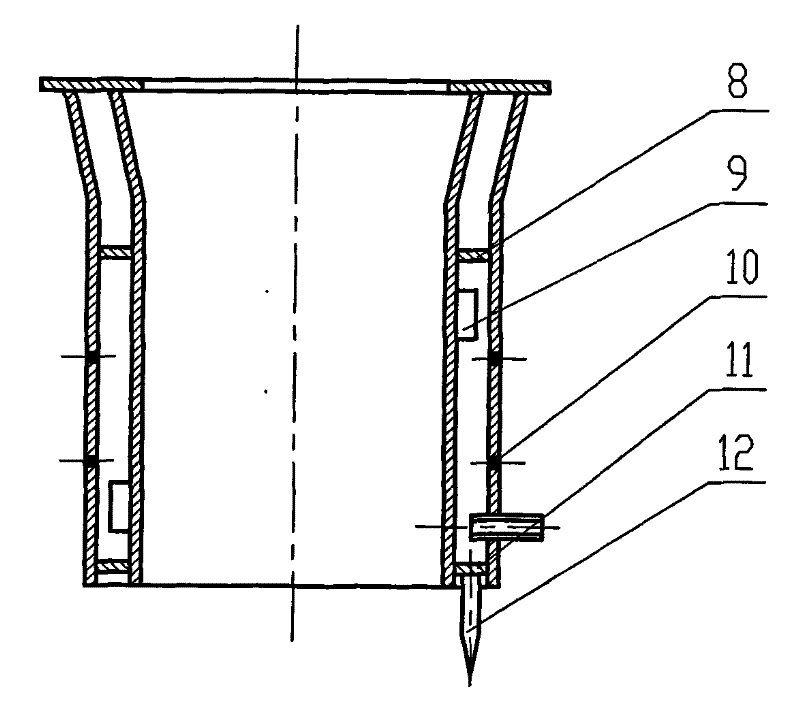

[0029] like Figure 1 to Figure 6 As shown, the inner heating type mold sleeve of the present invention has a conical top for convenient blanking; a reverse conical bottom for easy demoulding of the carbon block. The structure of the internal heating type die sleeve of the present invention is: a partition plate 5, a support plate 3 with holes 9, an upper cover plate 8 and a lower cover plate 11 are arranged between the outer wall 1 of the die sleeve and the inner wall 2 of the die sleeve, the outer wall of the die sleeve 1, The inner wall 2 of the mold case, the upper cover plate 8 and the lower cover plate 11 form a closed chamber, and the inner wall 2 of the mold case is welded to the support plate 3, the partition plate 5, the upper cover plate 8 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com