Clamping protection bushing of high-precision pipe for nuclear power and using method of clamping protection bushing

A protective bushing, high-precision technology, applied in the direction of clamping, maintenance and safety accessories, supports, etc., can solve the problems of increasing product quality control risks, unqualified pipe surface quality, and natural wear and tear are not easy to be found, etc., to achieve protection The effect of external surface quality, ease of promotion and use, and reduction of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

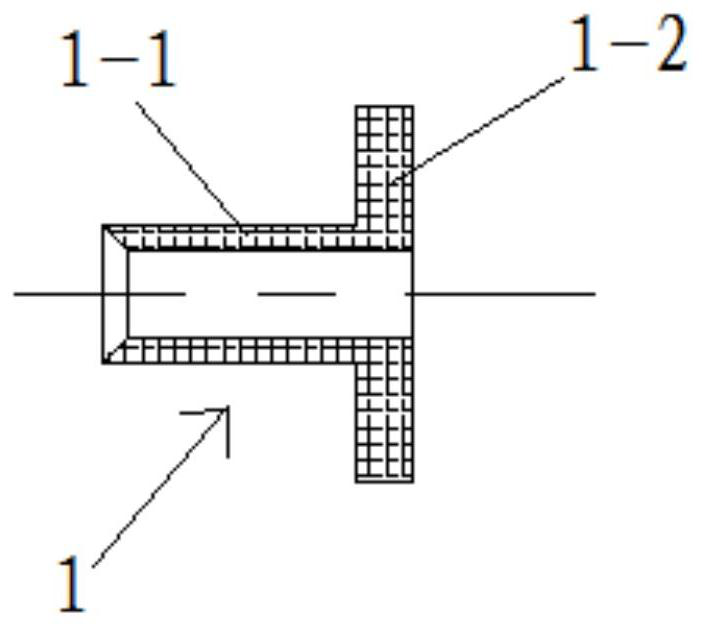

[0040] Such as figure 1 As shown, the protective bushing 1 includes an integrally formed working section 1-1 and a non-working section 1-2, the working section 1-1 and the non-working section 1-2 are hollow cylinder structures, and the working section 1 The outer diameter of -1 is smaller than the outer diameter of the non-working section 1-2, and the working section 1-1 and the non-working section 1-2 are coaxial and have the same inner diameter.

[0041] In this embodiment, the protective bushing 1 includes an integrally formed working section 1-1 and a non-working section 1-2, the working section 1-1 and the non-working section 1-2 are hollow cylinder structures, and the working section 1-1 The outer diameter of the protective bushing 1 is smaller than the outer diameter of the non-working section 1-2, and the working section 1-1 and the non-working section 1-2 are coaxial and have the same inner diameter. In actual use, the overall structure of the protective bushing 1 is ...

Embodiment 2

[0045] This embodiment includes the following steps:

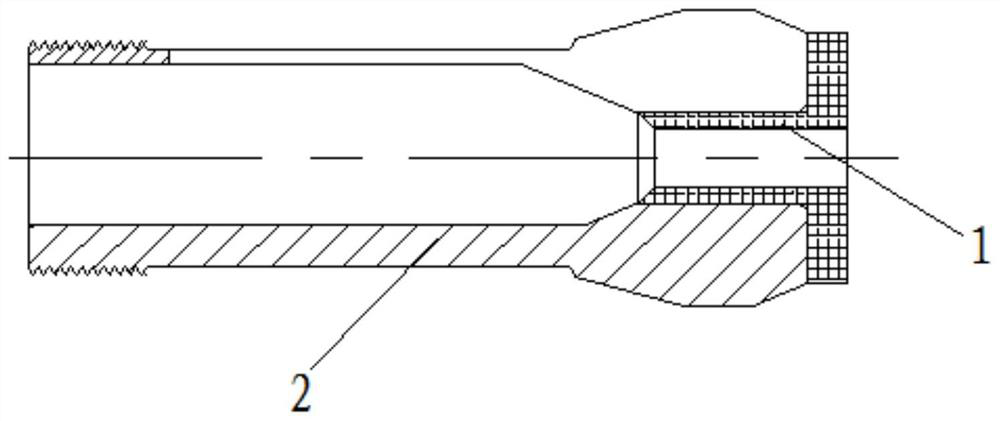

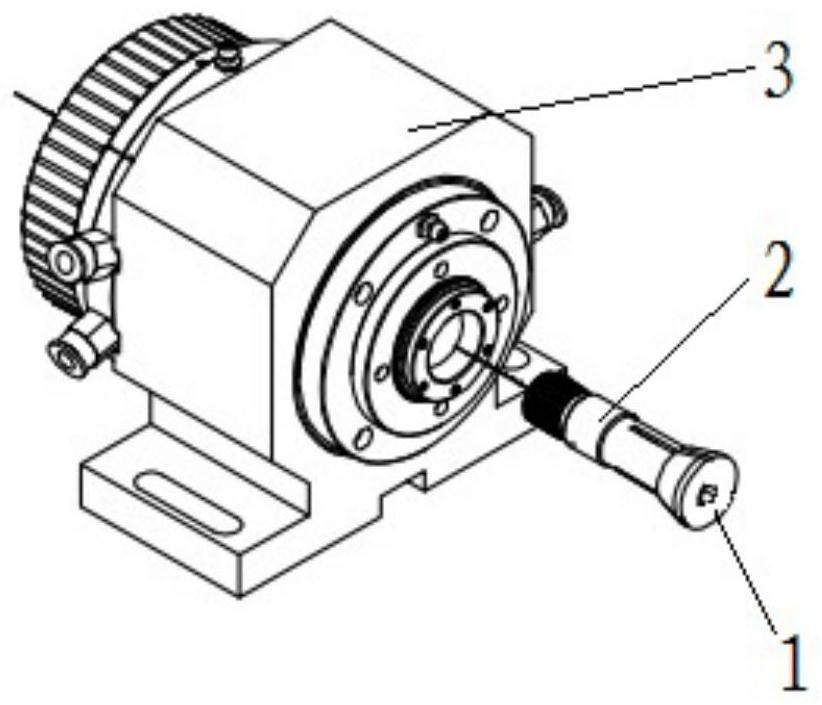

[0046] Step 1. Insert the working section 1-1 of the protective bush 1 into the collet 2 of the CNC lathe, make the working section 1-1 fit the clamping surface of the collet 2, and make the non-working section 1 of the protective bush 1 -2 is placed outside the collet 2 to obtain the assembled collet 2, see figure 2 The working section 1-1 of the protective bushing 1 is an interference fit with the collet 2 in a relaxed state; the interference fit of the interference fit is 0.13 mm; the Shore hardness of the protective bushing 1 is 80HA, the outer diameter of the working section 1-1 is 5.3mm, the outer diameter of the non-working section 1-2 is 15.3mm, the inner diameter of the working section 1-1 and the non-working section 1-2 are both 1.3mm, and the working section The length of 1-1 is 22mm, the length of non-working section 1-2 is 5mm, the coaxiality of working section 1-1 and non-working section 1-2 is 0.010mm; the...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] Step 1. Insert the working section 1-1 of the protective bush 1 into the collet 2 of the CNC lathe, make the working section 1-1 fit the clamping surface of the collet 2, and make the non-working section 1 of the protective bush 1 -2 is placed outside the collet 2 to obtain the assembled collet 2; the working section 1-1 of the protective bush 1 is in an interference fit with the collet 2 in a relaxed state; The margin is 0.15mm; the Shore hardness of the protective bush 1 is 85HA, the outer diameter of the working section 1-1 is 5.52mm; the outer diameter of the non-working section 1-2 is 14.52mm; the working section 1- The inner diameters of 1 and non-working section 1-2 are both 1.52mm; the length of working section 1-1 is 23mm; the length of non-working section 1-2 is 6mm; the same length of working section 1-1 and non-working section 1-2 The axis is 0.015mm; the surface roughness of the protective bush 1 is Ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com