Roller mold for processing seamless steel cylinder

A technology of cylinders and rollers, which is applied in the manufacturing field of high-pressure container processing equipment, can solve the problems of poor external surface quality of seamless steel cylinders, and achieve the effect of improving the quality of external surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

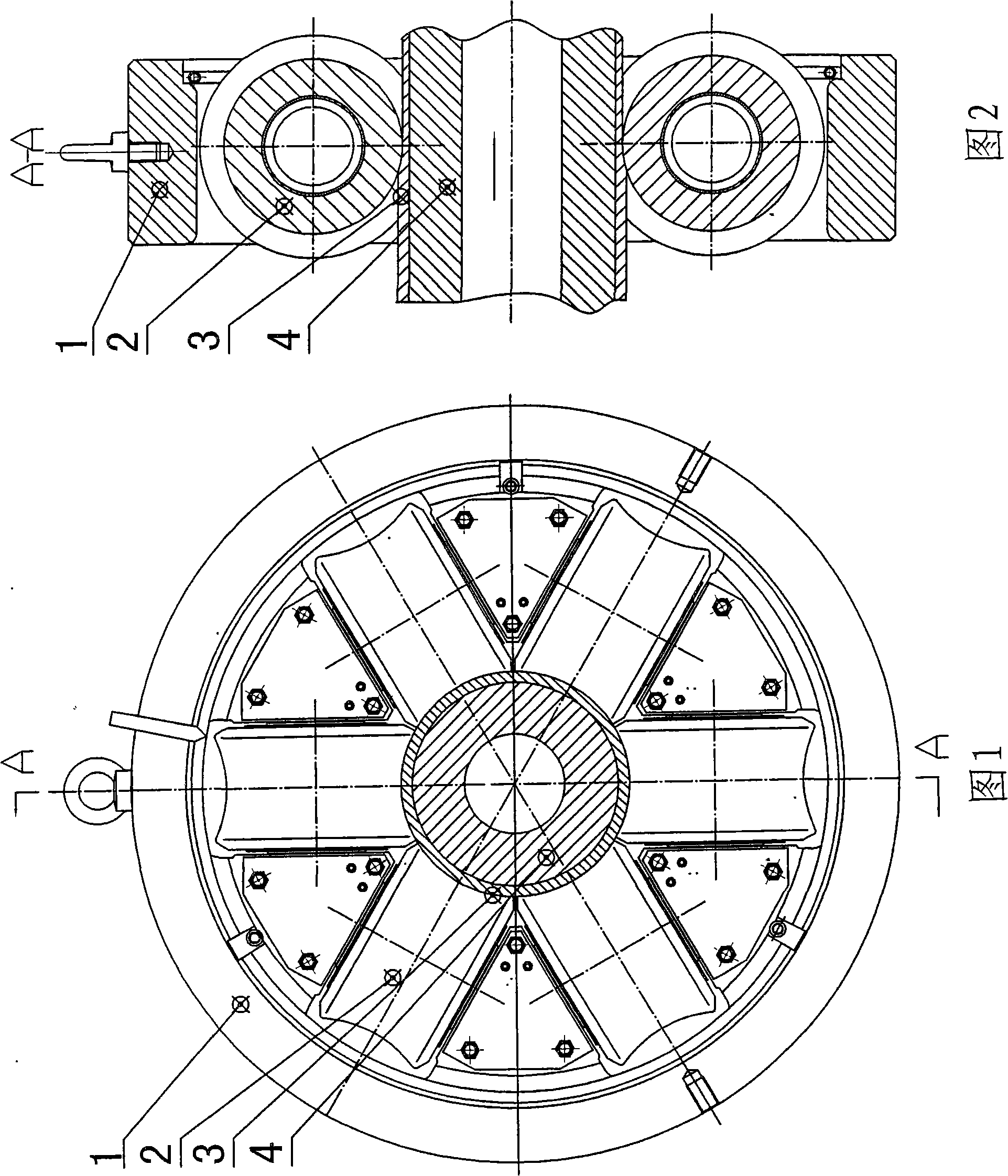

[0008] The present invention mainly consists of a roll mold frame 1, 5 to 8 uniformly distributed rolls 2 placed in the roll mold frame 1 and the like.

[0009] Shown in accompanying drawing 1 is an embodiment of the present invention, according to the scope of required processing seamless steel cylinder bottle body diameter, six rolls 2 are evenly arranged in the roll formwork 1, make the pass pattern that six rolls 2 form and no The standard outer diameter of the seamed steel cylinder body is more reasonable. When in use, under the push of the main water cylinder of the drawing and stretching press, the ejector rod 3 and the six rolls 2 carry out axial rolling on the body 4 of the seamless steel cylinder at the same time to complete the processing of the body of the seamless steel cylinder.

[0010] Although the present invention is illustrated and described according to one embodiment, the pass formed after the roll 2 is assembled is more reasonable and consistent with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com