Hydrolyzed polyacrylonitrile-compound ammonium salt for drilling fluid

A technology for hydrolyzing polyacrylonitrile and polyacrylonitrile ammonium salt, which is applied in the field of petroleum drilling aids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

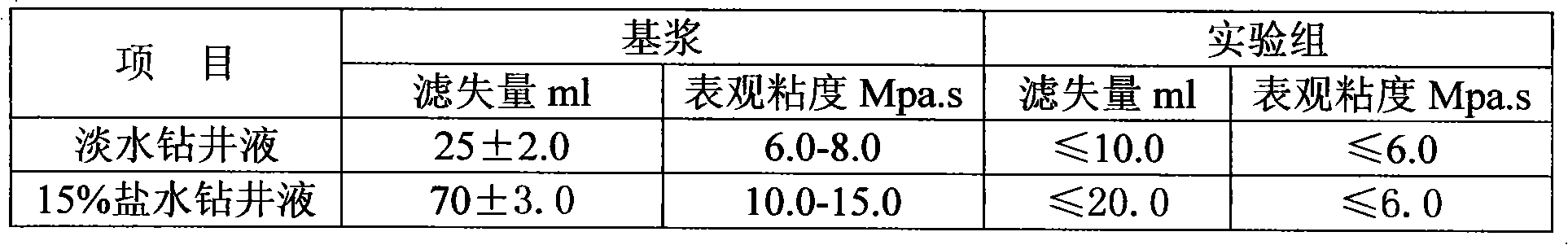

Examples

Embodiment 1

[0015] Example 1: The drilling fluid is hydrolyzed polyacrylonitrile-composite ammonium salt, which is based on hydrolyzed polyacrylonitrile ammonium salt as the main polymer, potassium polyacrylate, zwitterionic polymer fluid loss reducer JT888, polyacrylamide, nanmu powder As an auxiliary polymer, sodium hexametaphosphate is a mixture of six components of a flow regulator, and the weight percentage range of each component is 40% of hydrolyzed polyacrylonitrile ammonium salt, 10% of potassium polyacrylate, zwitterionic polymer Fluid loss reducer JT8885%, polyacrylamide 16%, nanmu powder 25%, sodium hexametaphosphate 4%.

[0016] The specific preparation method of the present invention is to take 40 kg of hydrolyzed polyacrylonitrile ammonium salt, 10 kg of potassium polyacrylate, 5 kg of zwitterionic polymer fluid loss reducer JT8885, 16 kg of polyacrylamide, 25 kg of nanmu powder, and 4 kg of sodium hexametaphosphate. Kg, respectively put into a (conventional) mixer, mix eve...

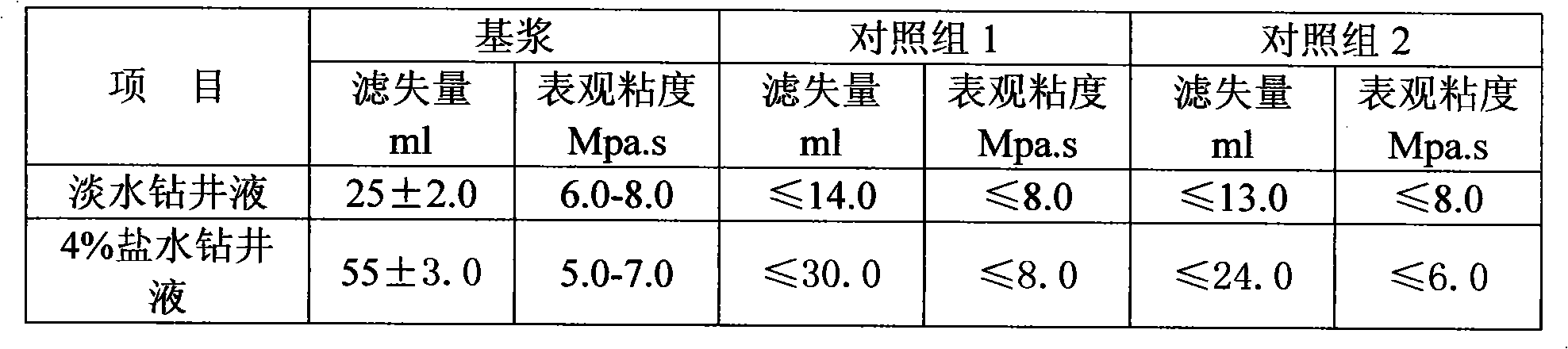

Embodiment 2

[0017] Embodiment 2: Drilling fluid hydrolyzed polyacrylonitrile-compound ammonium salt, it is based on hydrolyzed polyacrylonitrile ammonium salt as the main polymer, potassium polyacrylate, zwitterionic polymer fluid loss reducer JT888, polyacrylamide, nanmu powder As auxiliary polymer, sodium hexametaphosphate is mixed with six components of flow regulator.

[0018] The weight percent of each component can be: hydrolyzed polyacrylonitrile ammonium salt 40%, potassium polyacrylate 12%, zwitterionic polymer fluid loss reducer JT8882%, polyacrylamide 17%, nanmu powder 25%, hexametaphosphoric acid Sodium 4%.

[0019] Wherein the weight percent of each component can be: hydrolyzed polyacrylonitrile ammonium salt 45%, potassium polyacrylate 10%, zwitterionic polymer fluid loss reducer JT8882%, polyacrylamide 15%, nanmu powder 27%, hexametaphosphoric acid Sodium 1%.

[0020] Wherein the weight percent of each component can be: hydrolyzed polyacrylonitrile ammonium salt 43%, pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com