Supersonic electromagnetic-induction heating equipment

An electromagnetic induction heating and heating equipment technology, which is applied in lighting and heating equipment, heating methods, electric heating systems, etc., can solve the problems that electromagnetic heating cannot be intelligently controlled and has complex structures, and achieves low daily maintenance costs, compact equipment pipelines, The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings.

[0025] The super audio frequency electromagnetic induction heating heating device of the present invention has a working frequency range of 20 kHz to 30 kHz super audio frequency band.

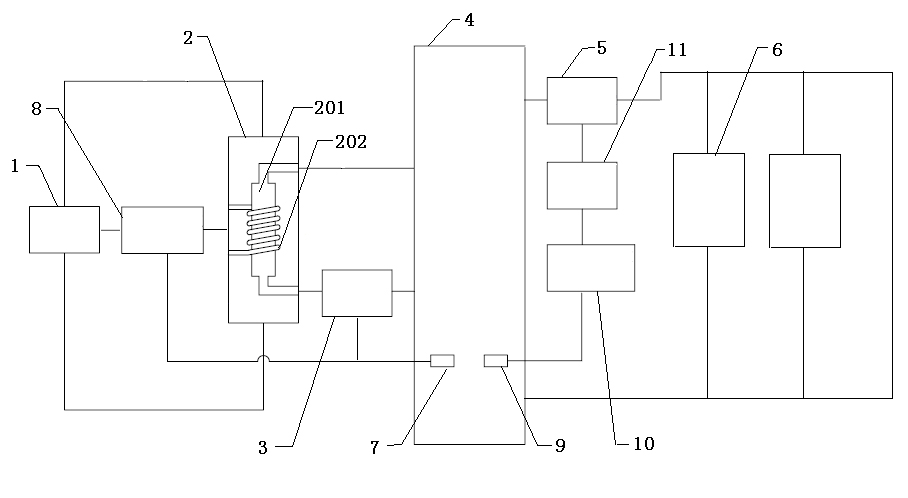

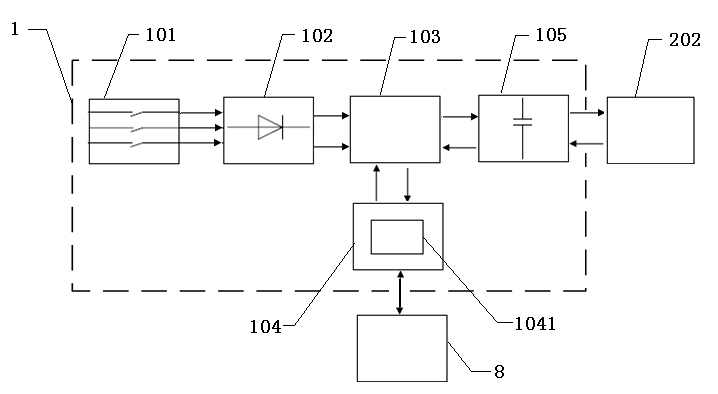

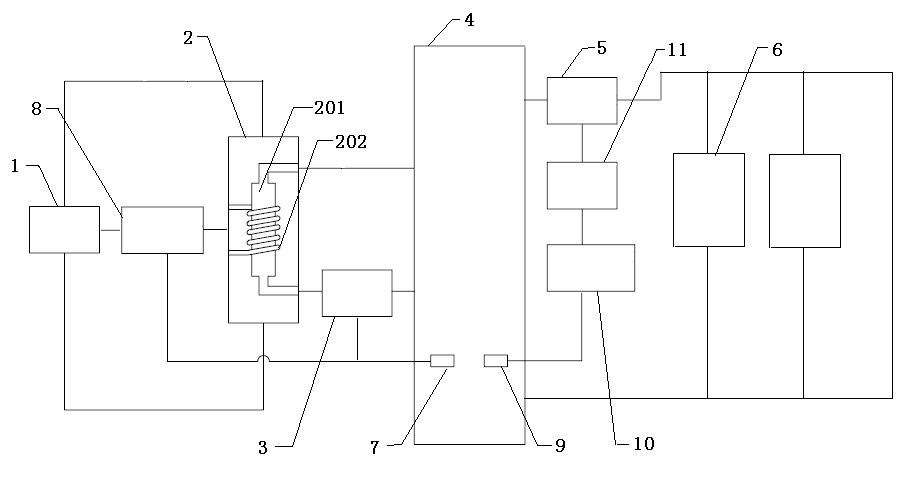

[0026] Such as figure 1 As shown, the super-audio electromagnetic induction heating heating equipment of the present invention includes a super-audio power control system 1, a super-audio electromagnetic induction heating device 2, a first circulating pump 3, a heat storage device 4, a second circulating pump 5 and a heat sink 6. The super-audio electromagnetic induction heating device 2, the first circulating pump 3, and the heat storage device 4 are connected in sequence through pipelines to form a heat storage cycle system, and the heat storage device 4, the second circulating pump 5 and the heat sink 6 are connected in turn through pipelines to form heating Circulation system. A first temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com