Hydrogen generator

A technology for generating devices and containers for hydrogen production, hydrogen, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

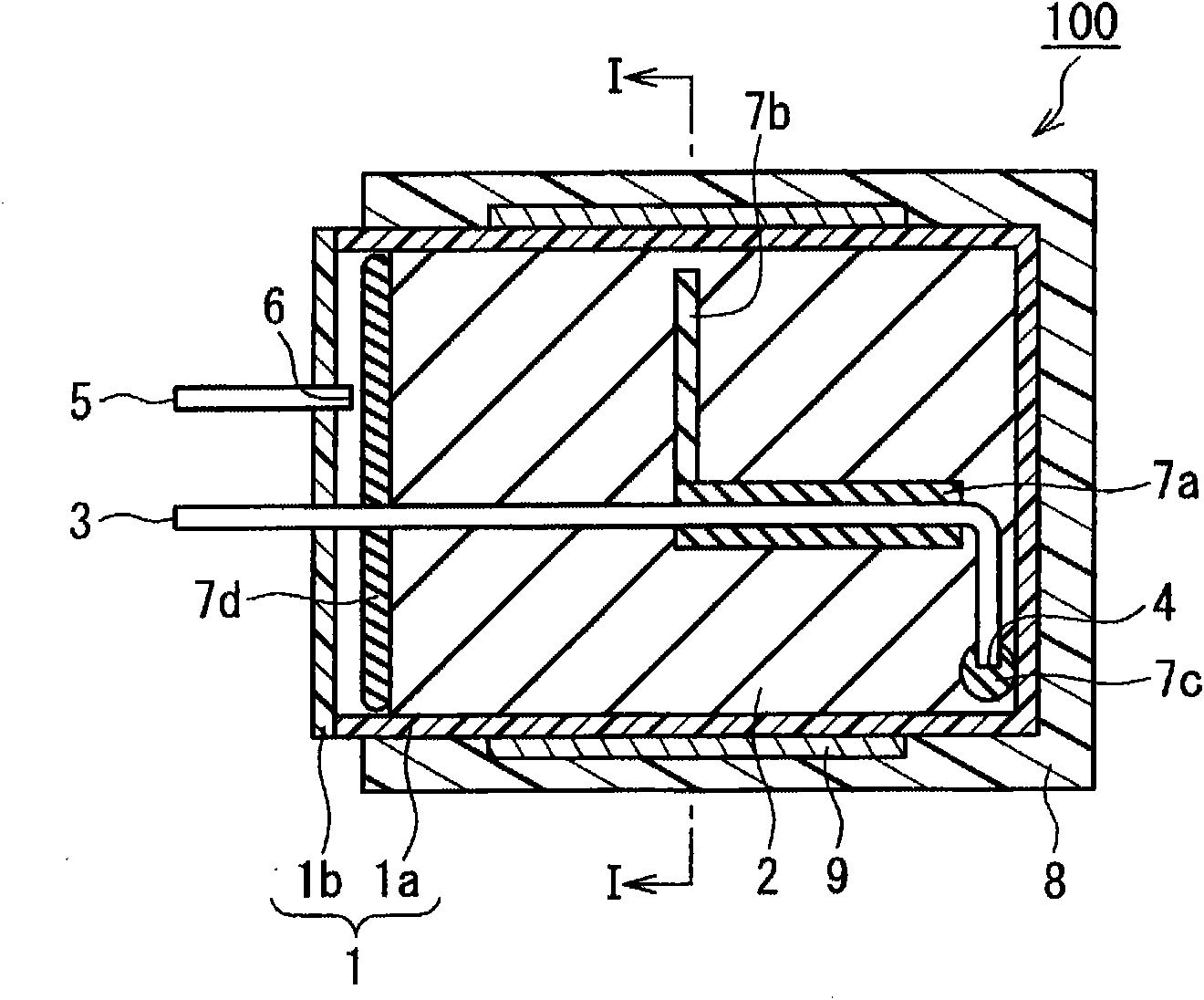

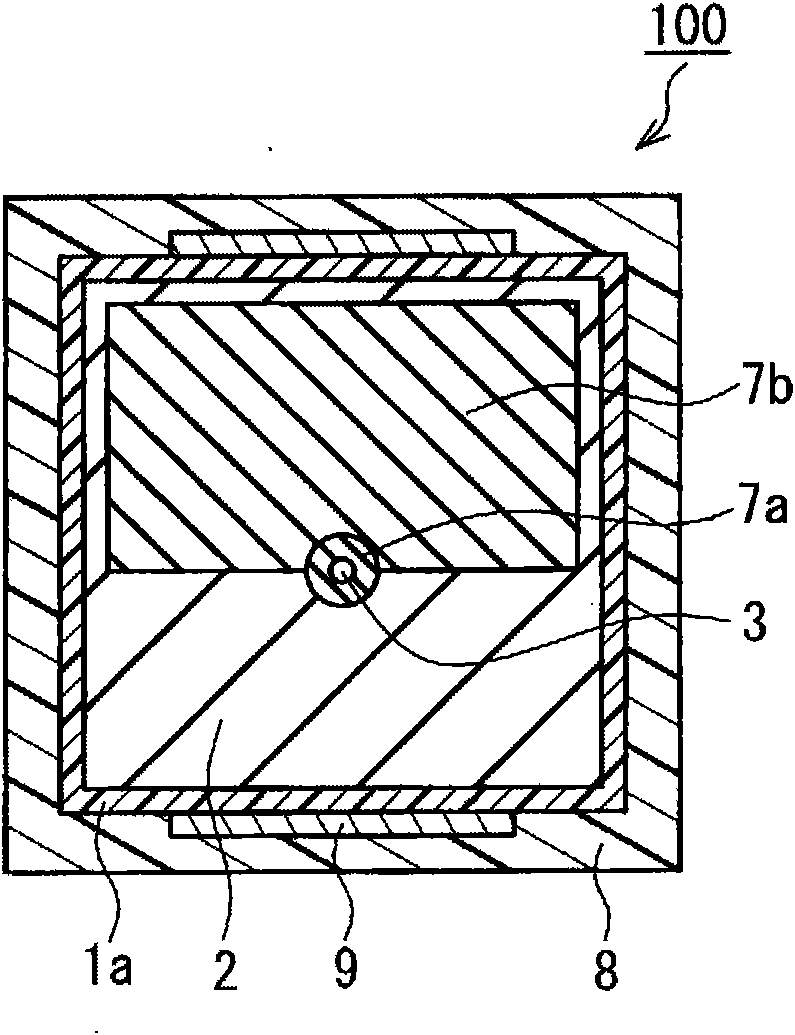

[0091] use Figure 4 Shown is a fuel cartridge 100 representing one example of a hydrogen generating device of the present invention, producing hydrogen as described. Figure 5 for, Figure 4 Sectional view in the arrow direction of line II-H. exist Figure 4 and Figure 5 in, with figure 1 and figure 2 The same symbols are assigned to the same parts, and detailed description thereof will be omitted. later mentioned Figure 6-10 the same.

[0092] Hydrogen generating material A was produced by mixing 1.0 g of aluminum powder with an average particle diameter of 6 μm as a metal material and 1.0 g of calcium oxide powder with an average particle diameter of 3 μm as an exothermic material in a mortar. In addition, hydrogen generating material B was produced by mixing 98.5 g of the above-mentioned aluminum powder as a metal material and 12.5 g of the above-mentioned calcium oxide powder as an exothermic material in a mortar.

[0093] Then, inside the container 1 (length ...

Embodiment 2~3

[0099] A hydrogen generator was produced in the same manner as in Example 1, except that absorbent cotton was disposed on the outer periphery of the water supply pipe 3 as the water absorbing material 7a under the arrangement conditions shown in Table 1. Next, hydrogen was generated in the same manner as in Example 1, and the reaction rate was measured.

Embodiment 4

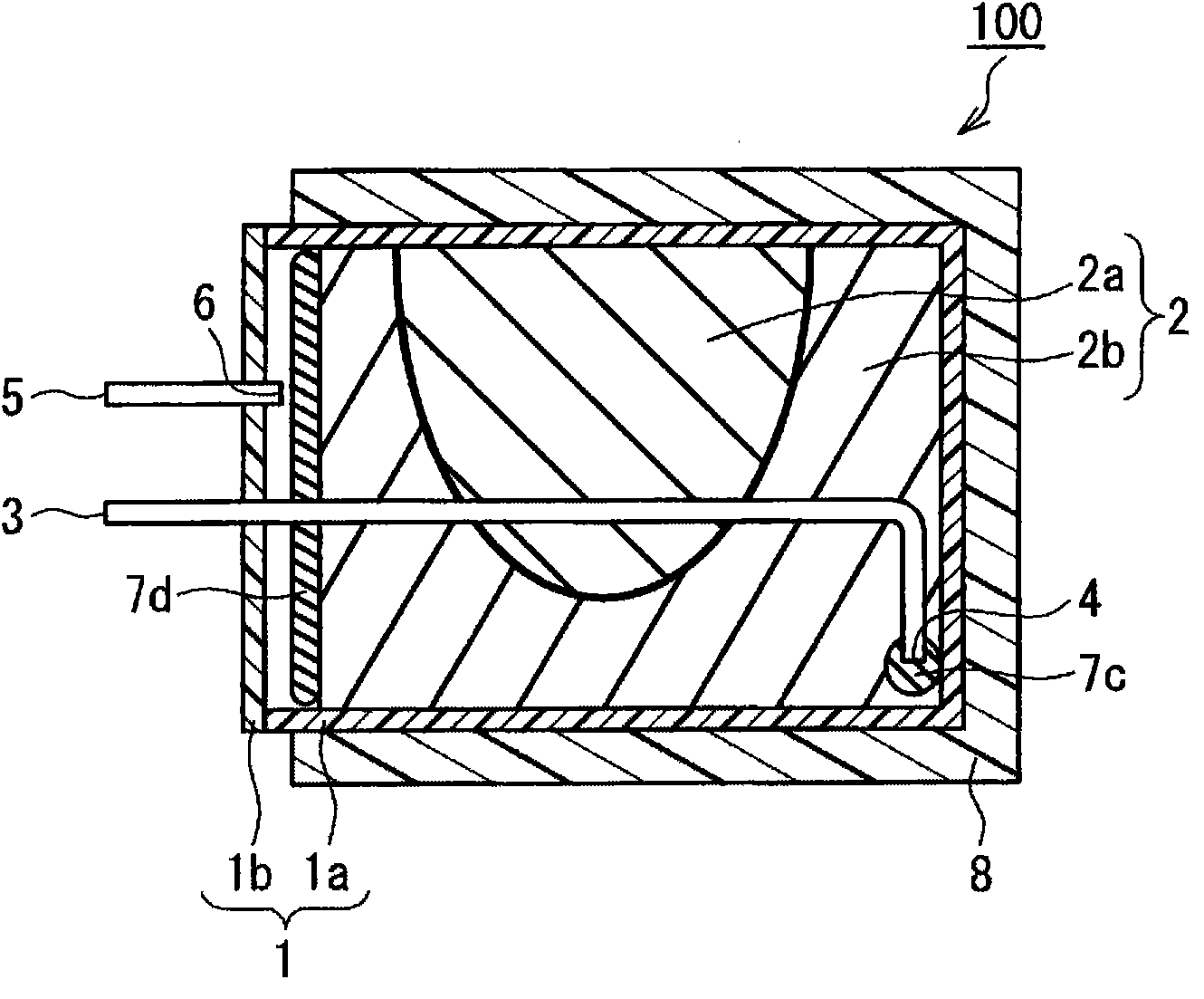

[0101] Such as Figure 6 and Figure 7 As shown, except that 0.2 g of absorbent cotton was disposed as the water-absorbing material 7b, a hydrogen generator was manufactured in the same manner as in Example 1. That is, in Figure 6 and Figure 7 In this case, the absorbent material 7b further extends from the front end of the water absorbent material 7a on the opposite side of the reference plane to the upper wall surface of the container 1, and the absorbent material 7b does not contact the wall surface. Next, hydrogen was generated in the same manner as in Example 1, and the reaction rate was measured. It should be noted, Figure 6 It is a schematic sectional view of a fuel cartridge used in this example, Figure 7 for Figure 6 Sectional view in the arrow direction of line III-III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com