Film forming source, deposition apparatus and apparatus for manufacturing organic el element

A film-forming source and evaporation technology, applied in electrical components, lighting devices, vacuum evaporation coating, etc., can solve problems such as damage, deterioration of substrate film quality, deterioration of organic thin film thickness distribution, etc. Long life and small movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

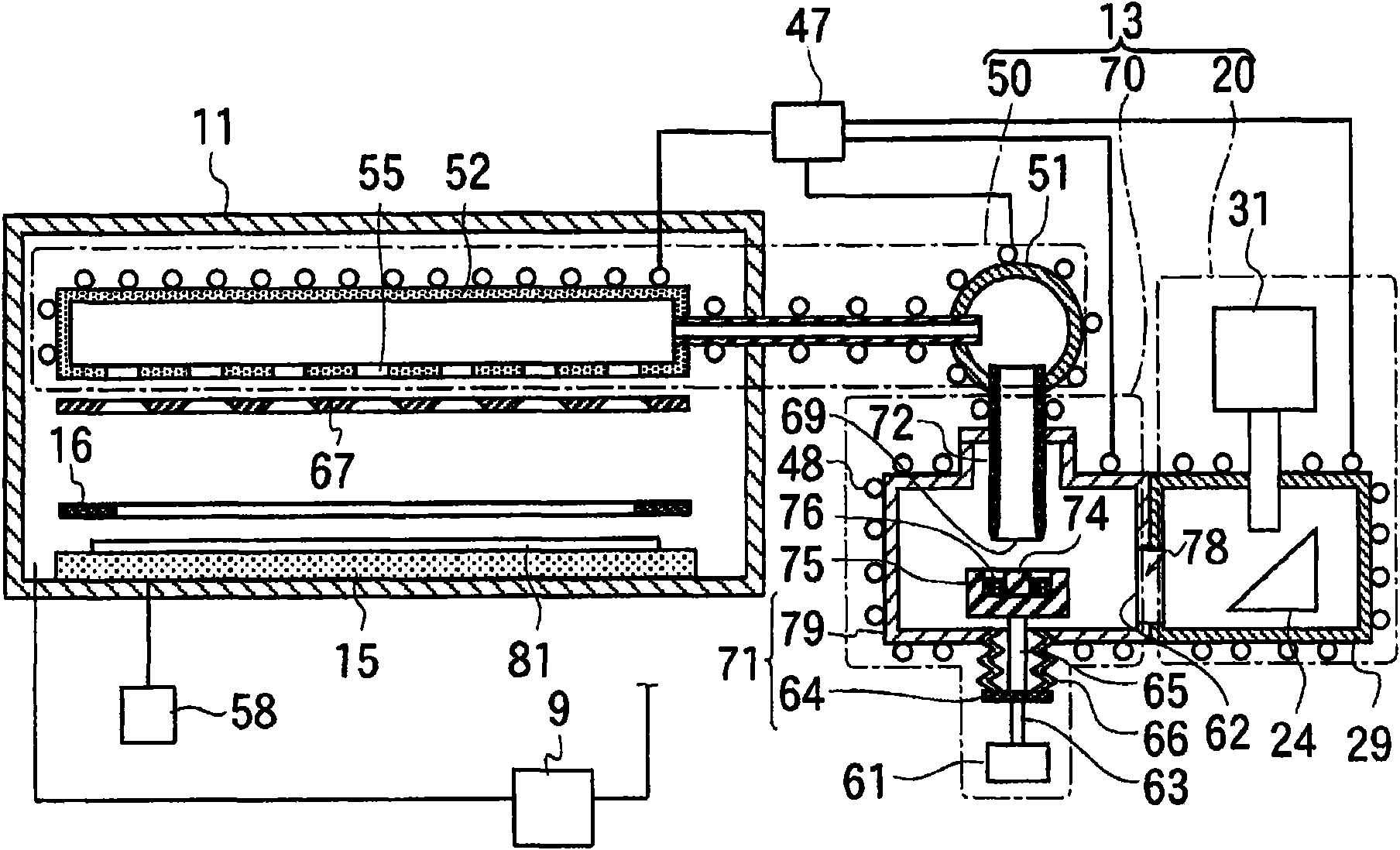

[0052] The on-off valve of the present invention has a housing as a box, and an opening and closing port and a connecting port that communicate the inside and outside of the housing, and the on-off valve can pass between the opening and closing port and the connecting port through the inside of the housing for gas. Switch between the connection state and the shielded state between the opening and closing port and the connection port. The box is configured airtight and can be vacuum-exhausted.

[0053] The on-off valve according to the present invention has a container arranged in a housing and capable of arranging solids and liquids, and a shielding member arranged in the housing.

[0054] The container and the shielding member are configured to be relatively movable, and the shielding member is configured to be able to be inserted into and removed from the container. The opening and closing opening is surrounded by either the shielding member or the container.

[0055] A lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com