Self-heating laminate plate for building and manufacturing method thereof

A laminated board and construction technology, applied in the field of laminated boards, can solve the problems of laminated boards without self-heating, loss of antibacterial, deodorizing, and reduced strength of boards, etc., to achieve low production costs, cost savings, and indoor space big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] First, configure the mixed raw materials according to the following ratio:

[0018] Loess 43%

[0020] 27% magnesium chloride solution 17%

[0021] Resin 5%

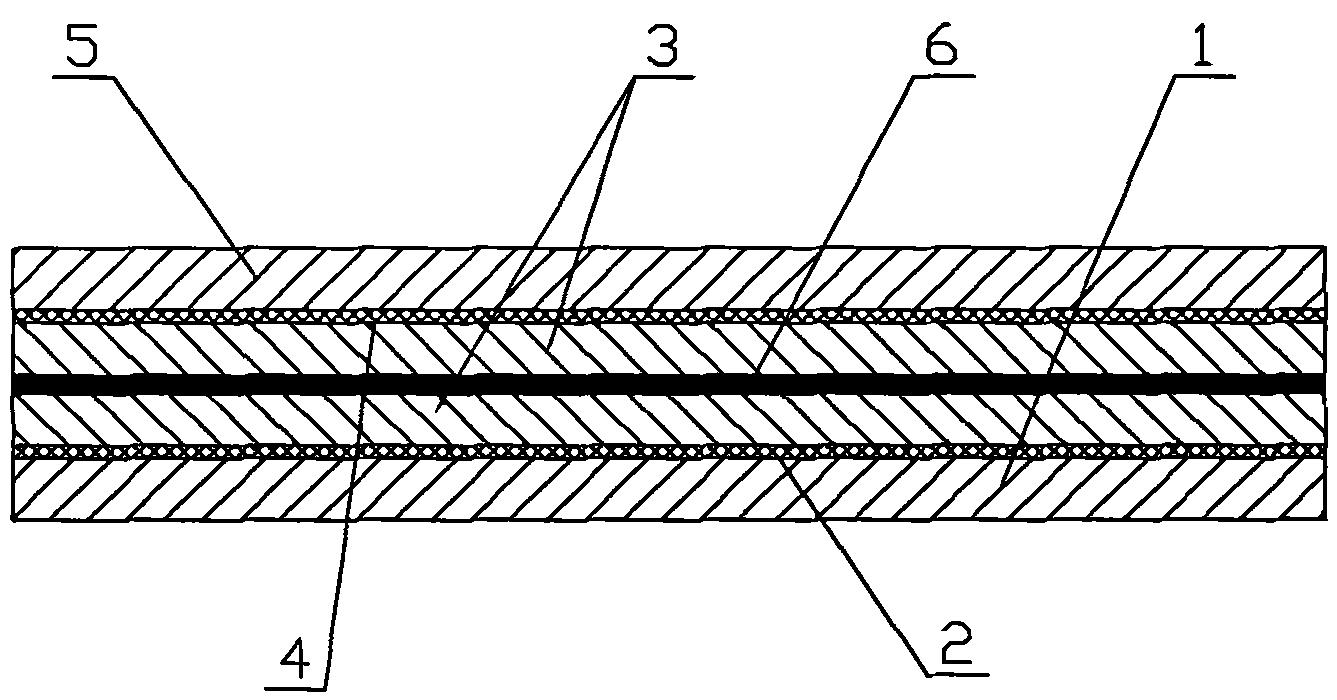

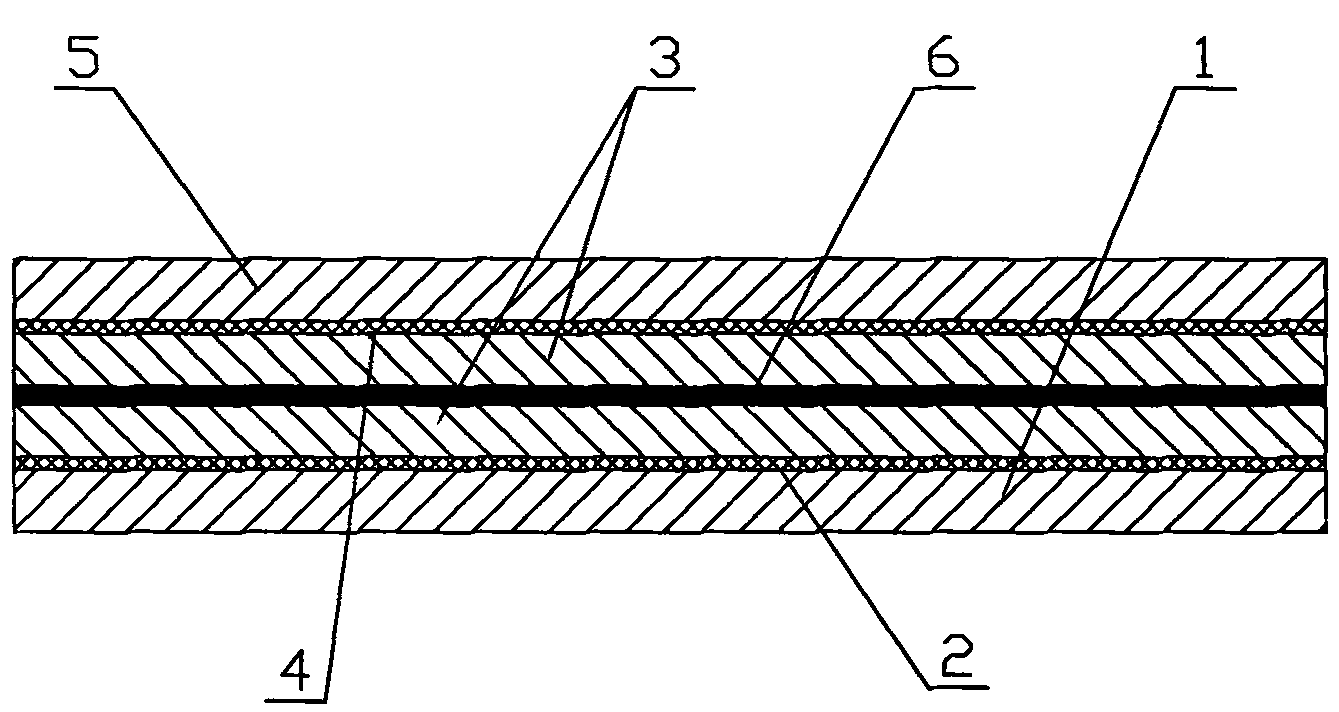

[0022] Smear the above-mentioned raw material in mud form on the processing panel as the bottom layer 1, then cover it with the reinforced mesh 2, and then apply a layer of the above-mentioned raw material as the middle layer 3, and set the electric heating in the center of the middle layer 3 layer 6, and expose the two contacts of the electric heating layer 6; then cover the reinforcement mesh 4 above the middle layer 3, and finally apply a layer of the above-mentioned raw materials as the top layer 5; the self-heating laminate of the six-layer structure Cut the board, cut it into the required size and shape of the board, and let it stand in an environment of 23 degrees Celsius for 8 hours to complete the production of the laminated board.

Embodiment 2

[0024] First, configure the mixed raw materials according to the following ratio:

[0025] Mica 36%

[0027] 22% magnesium chloride solution 16%

[0028] Resin 6%

[0029] Smear the above-mentioned raw material in mud form on the processing panel as the bottom layer 1, then cover it with the reinforced mesh 2, and then apply a layer of the above-mentioned raw material as the middle layer 3, and set the electric heating in the center of the middle layer 3 layer 6, and expose the two contacts of the electric heating layer 6; then cover the reinforcement mesh 4 above the middle layer 3, and finally apply a layer of the above-mentioned raw materials as the top layer 5; the self-heating laminate of the six-layer structure The board is cut, cut into boards of the required size and shape, and left to stand in an environment of 20 degrees Celsius for 12 hours to complete the production of laminated boards.

[0030] When heating is required, the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com