Vehicle-mounted oiling steam reclamation and fuel oil liquid level controlling decompression integrated device

A technology of liquid level control and integrated device, which is applied to the power plant, the layout combined with the fuel supply of the internal combustion engine, and the vehicle components, etc., can solve the problem that the oil tank is not sealed, the gasoline liquid affects the recovery efficiency of the activated carbon canister, and the oil vapor evaporation of the oil tank. It can reduce the risk, improve the sensitivity and reliability, and simplify the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

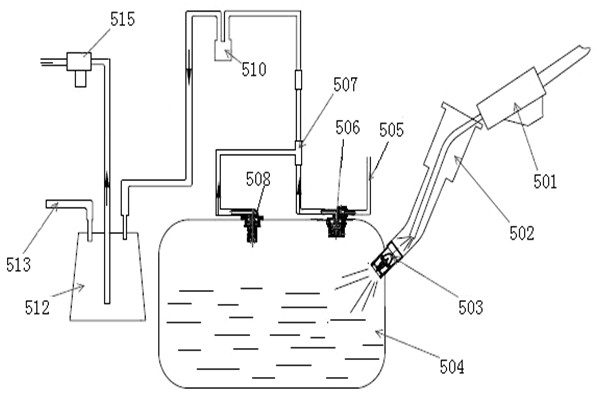

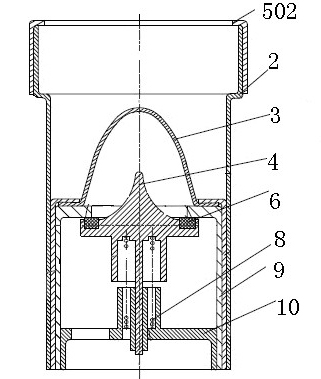

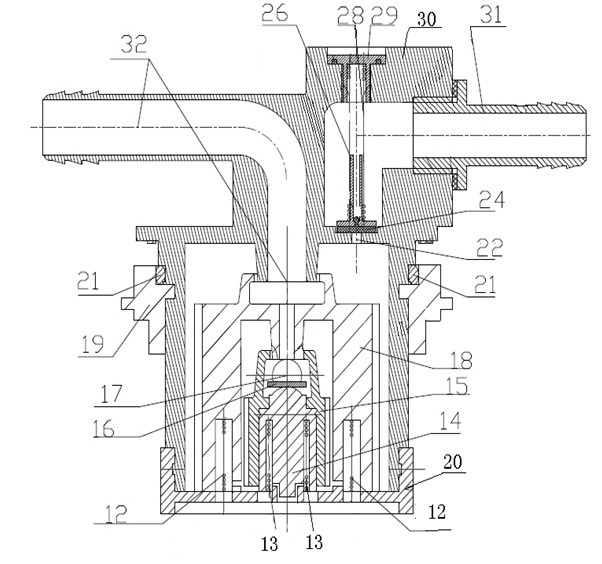

[0015] see figure 1 , the present invention comprises a fuel tank 504 and a refueling pipe 502, the top of the refueling pipe 502 is connected to a refueling gun 501, the bottom of the refueling pipe 502 is equipped with a check valve 503, and the refueling pipe 502 is connected to the fuel tank 504 through the check valve 503 installed at the bottom. A check valve 503, a slope valve 508 and a fuel level control pressure relief valve 506 are fixedly installed on the body of the fuel tank 504, and the slope valve 508 and the fuel level control pressure relief valve 506 are connected in parallel to the parallel connection pipe 507 by connecting pipes After parallel connection, the connecting pipe 507 is connected to the gas-liquid separator 510 and the activated carbon canister 512 in turn through the connecting pipe, and the upper port of the activated carbon canister 512 is respectively connected to the solenoid valve 515 and the carbon canister ventilation valve 513 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com