Wood asphalt mixture used for paving side pavement and preparation method thereof

A technology for asphalt mixtures and sidewalks, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as lack of promotion and permanent application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

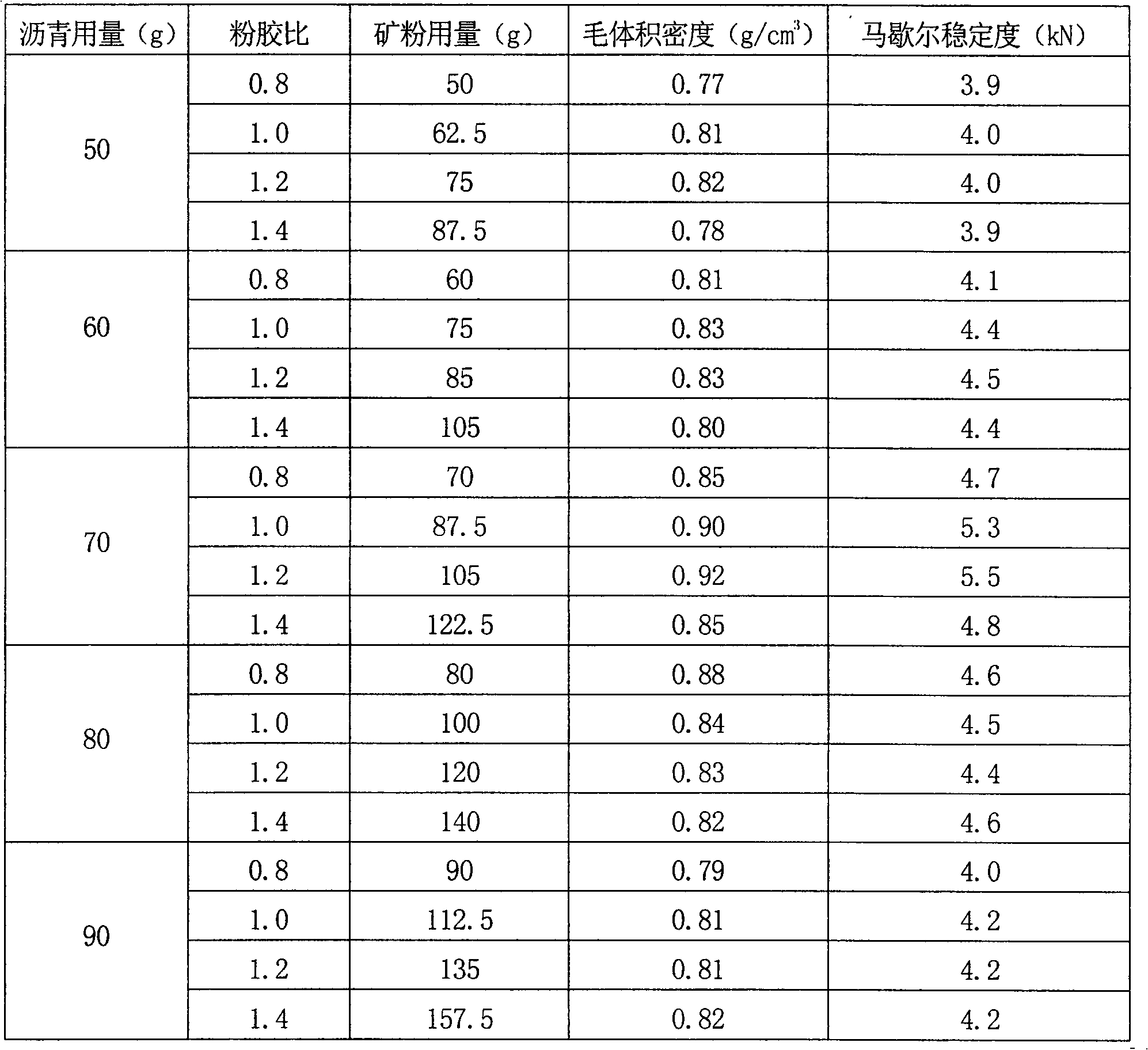

Method used

Image

Examples

Embodiment 1

[0030] Taking the preparation of sidewalk pavement of the present invention with wooden asphalt mixture 1000g as example used raw material and consumption thereof are:

[0031] SK-70# base asphalt 161.5g

[0032] Coarse wood aggregate 369.1g

[0033] Fine wood aggregate 203g

[0034] Mineral powder 242.2g

[0035] TPS modifier 24.2g

[0036] The mass parts of the above-mentioned raw materials are as follows:

[0037] SK-70# base asphalt 7.0 parts

[0038] Coarse wood aggregate 16.0 parts

[0039] Fine wood aggregate 8.8 parts

[0040] Mineral powder 10.5 parts

[0041] TPS modifier 1.05 parts

[0042] The above-mentioned SK-70# matrix asphalt is provided by Shaanxi Wentong Road Material Co., Ltd.; coarse wood aggregates are broken pine wood with a particle size greater than 4.75mm and less than or equal to 16mm, and coarse wood aggregates with a particle size greater than 4.75mm and less than or equal to 9.5mm The mass ratio of coarse woody aggregates with a particle ...

Embodiment 2

[0051]Taking the preparation of sidewalk pavement of the present invention with wooden asphalt mixture 1000g as example used raw material and consumption thereof are:

[0052] SK-70# base asphalt 175.4g

[0053] Coarse wood aggregate 350.9g

[0054] Fine wood aggregate 175.4g

[0055] Mineral powder 280.8g

[0056] TPS modifier 17.5g

[0057] The mass parts of the above-mentioned raw materials are as follows:

[0058] SK-70# base asphalt 5.0 parts

[0059] Coarse wood aggregate 10.0 parts

[0060] Fine wood aggregate 5.0 parts

[0061] Mineral powder 8.0 parts

[0062] TPS modifier 0.5 parts

[0063] Every index of above-mentioned raw material is identical with embodiment 1.

[0064] Its preparation method is identical with embodiment 1.

Embodiment 3

[0066] Taking the preparation of sidewalk pavement of the present invention with wooden asphalt mixture 1000g as example used raw material and consumption thereof are:

[0067] SK-70# base asphalt 153.8g

[0068] Coarse wood aggregate 307.8g

[0069] Fine wood aggregate 256.4g

[0070] Mineral powder 256.4g

[0071] TPS modifier 25.6g

[0072] The mass parts of the above-mentioned raw materials are as follows:

[0073] SK-70# base asphalt 9.0 parts

[0074] Coarse wood aggregate 18.0 parts

[0075] Fine wood aggregate 15.0 parts

[0076] Mineral powder 15.0 parts

[0077] TPS modifier 1.5 parts

[0078] Every index of above-mentioned raw material is identical with embodiment 1.

[0079] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com