Continuous ion exchange device and method for extracting gallium from Bayer mother solution

A technology of continuous ion and exchange device, applied in the direction of improving process efficiency, can solve problems such as complex process and resin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

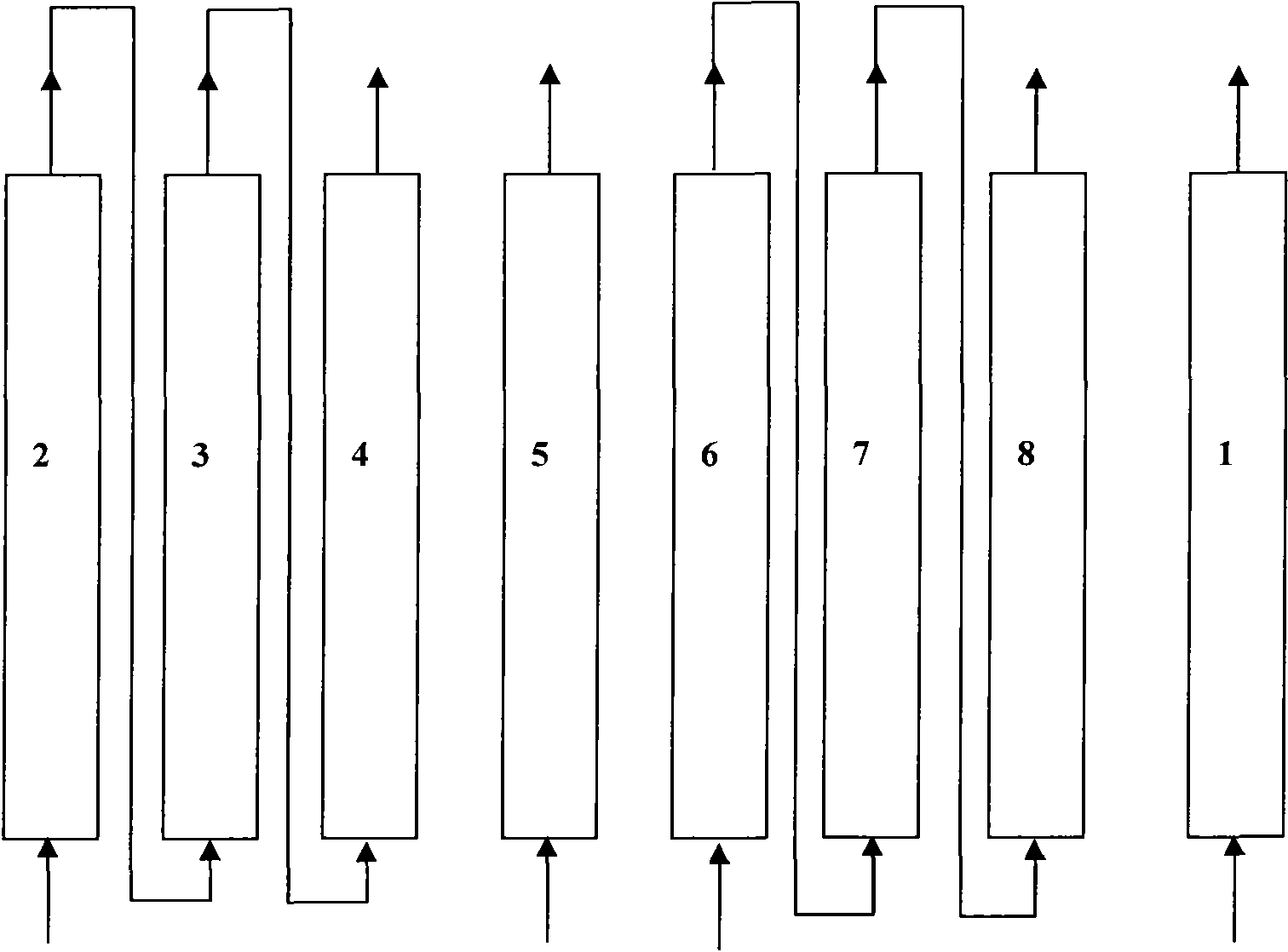

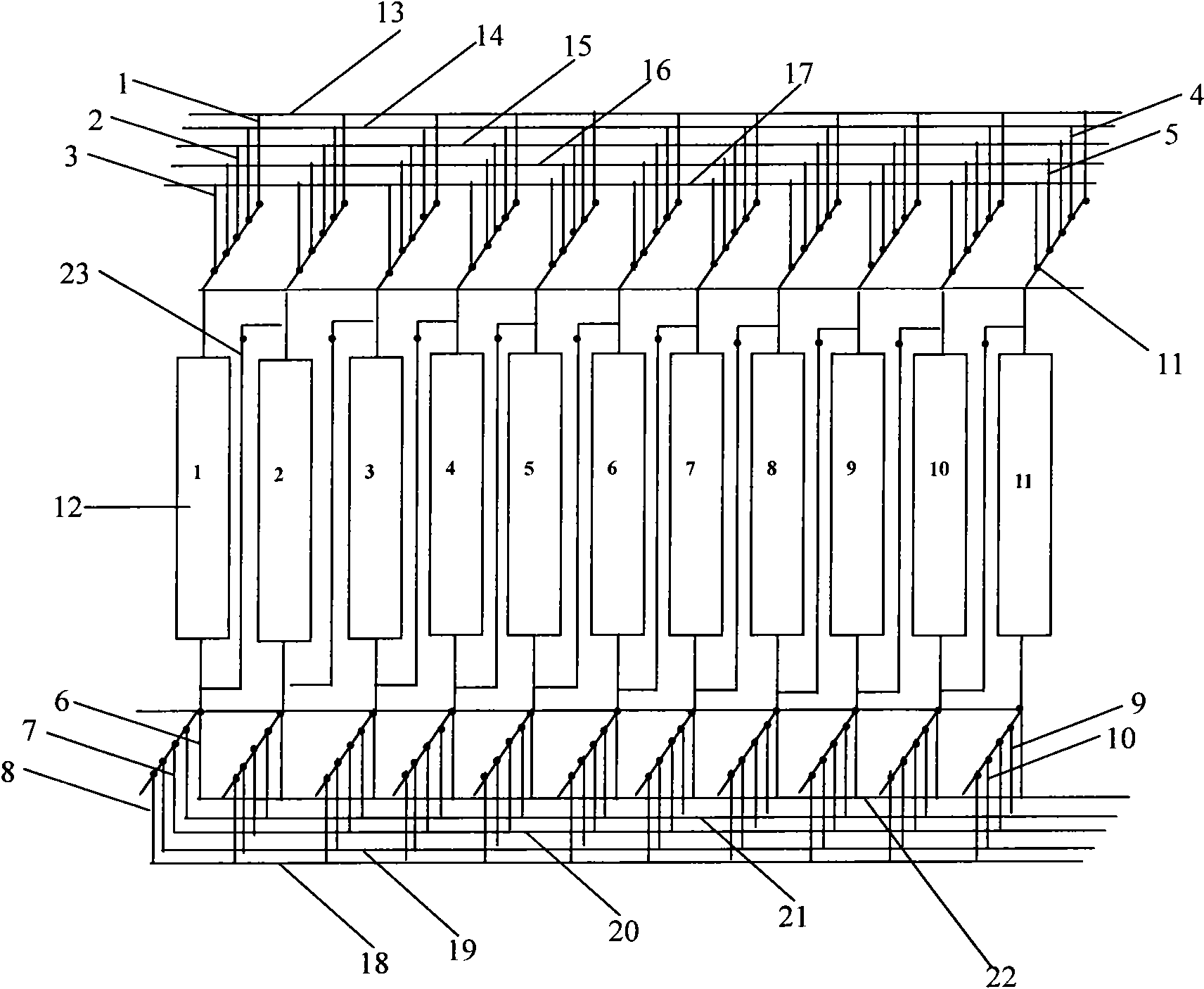

[0093] like figure 2As shown in the figure, the continuous ion exchange device for extracting gallium from Bayer mother liquor provided by the present invention includes resin, a plurality of resin columns for loading resin, a discharge manifold communicated with the upper end of the resin column, and a feed material communicated with the lower end of the resin column The main pipe connects multiple resin columns in series to form four series of resin column groups, namely adsorption resin column group, washing resin column group, rinsing resin column group and transformation resin column group;

[0094] Feed headers include Bayer mother liquor feed header, wash feed header, rinse feed header, and transformation feed header, and outlet headers include Bayer mother liquor outlet header, wash outlet header, rinse outlet header, and transformation outlet A main pipe, each resin column group is respectively provided with a feed branch pipe communicated with the feed main pipe and...

Embodiment 2

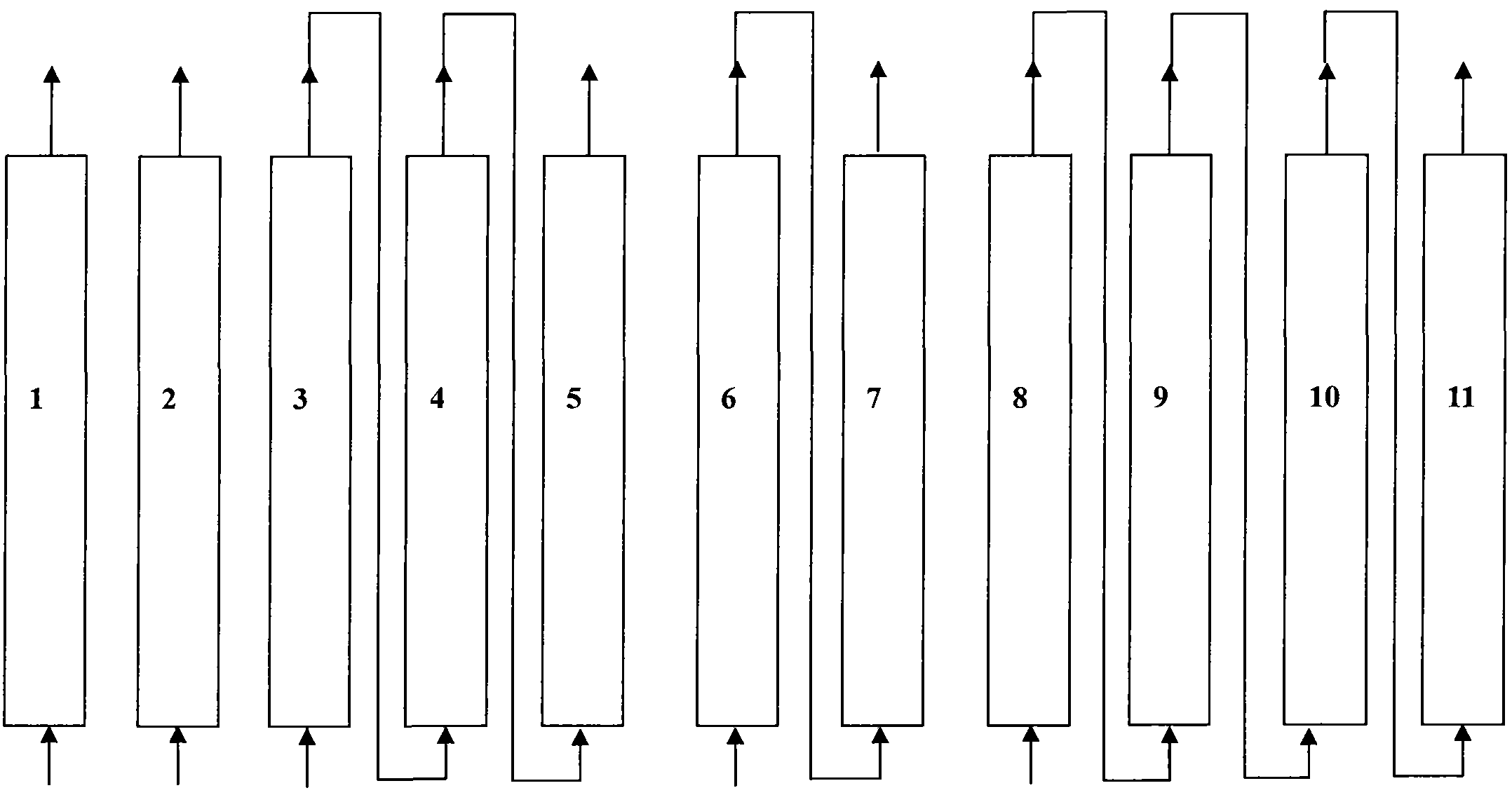

[0114] like figure 1 As shown in the figure, the continuous ion exchange device for extracting gallium from Bayer mother liquor provided by the present invention includes resin, a plurality of resin columns for loading resin, a discharge manifold communicated with the upper end of the resin column, and a feed material communicated with the lower end of the resin column In the main pipe, a plurality of resin columns are sequentially connected in series to form five series of resin column groups, namely adsorption resin column group, saturated-wash resin column group, rinse resin column group, rinsing resin column group and transformation resin column group;

[0115] The feed manifold includes Bayer mother liquor feed manifold, saturated wash feed manifold, rinse feed manifold, rinse feed manifold and transformation feed manifold, and the discharge manifold includes Bayer mother liquor discharge manifold, saturated wash discharge manifold, and rinse out manifold. A material main...

Embodiment 3

[0140]The structure of the continuous ion exchange device for extracting gallium from Bayer mother liquor is the same as in Example 2, wherein the number of series resin columns in the adsorption resin column group is 3; the number of series resin columns in the saturated resin column group is 1; the rinse resin column group The number of series-connected resin columns is 1; the number of series-connected resin columns in the eluting resin column group is 3; the number of series-connected resin columns in the transformation resin column group is 2. The adsorption resin loaded in the resin column is SEPLITE LSC-600 resin (Xi'an Lanxiao Technology Co., Ltd.).

[0141] Wherein: the feeding time is 60min, the superficial linear velocity of the mother liquid feed liquid is 30m / h, the superficial linear velocity of the washing liquid is 15m / h, the superficial linear velocity of the rinsing liquid is 15m / h, and the rinsing The superficial linear velocity of the liquid is 12m / h, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com