Seed cotton opening device of seed cotton foreign fiber stripping machine

A technology of opening device and cleaning machine, which is applied in the direction of fiber opening and cleaning machines, opening and cleaning combined machines, etc., which can solve the problems of high labor intensity, large power consumption, and multiple transmissions, and achieve improved opening quality and high opening efficiency , Good loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

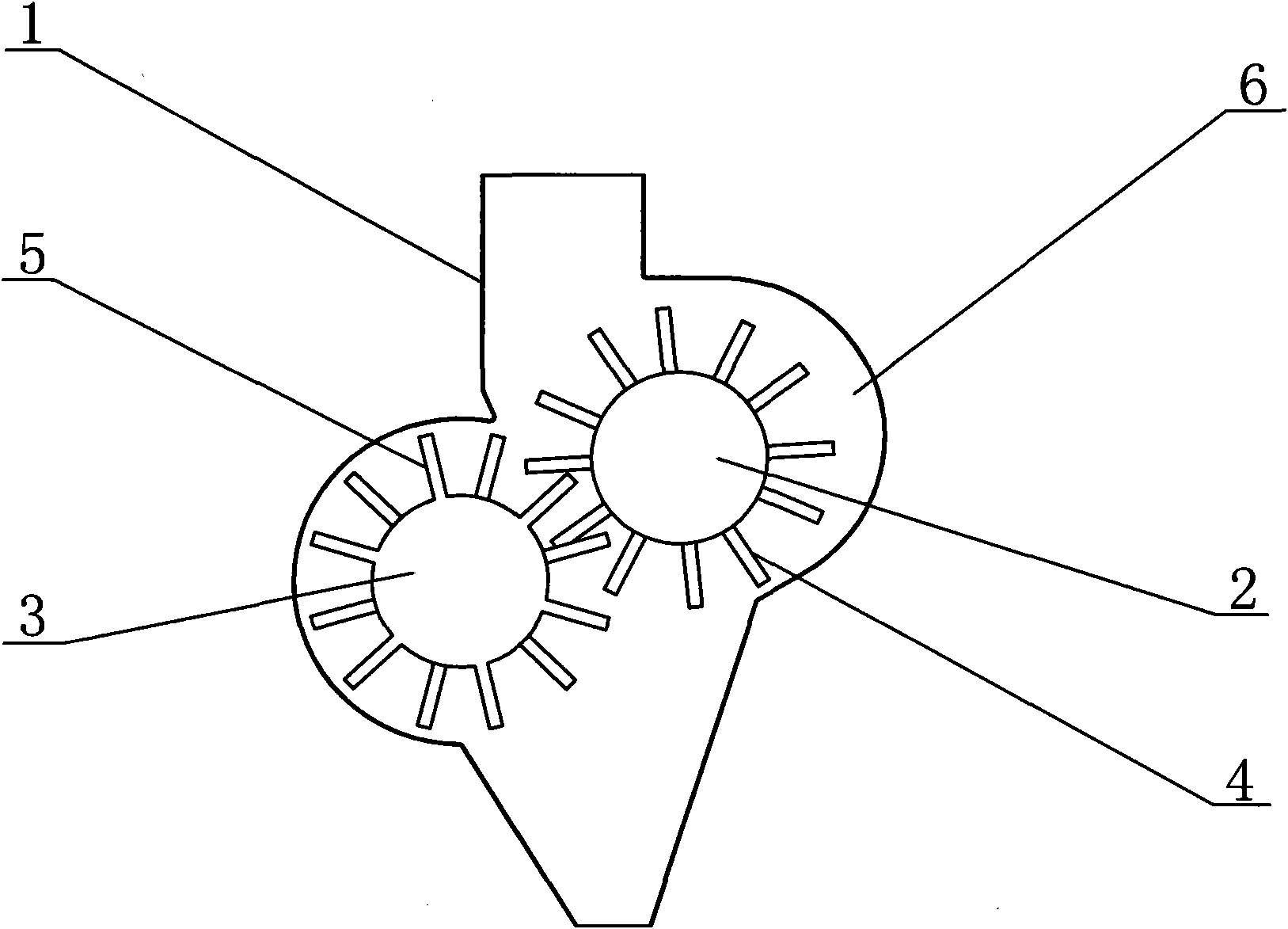

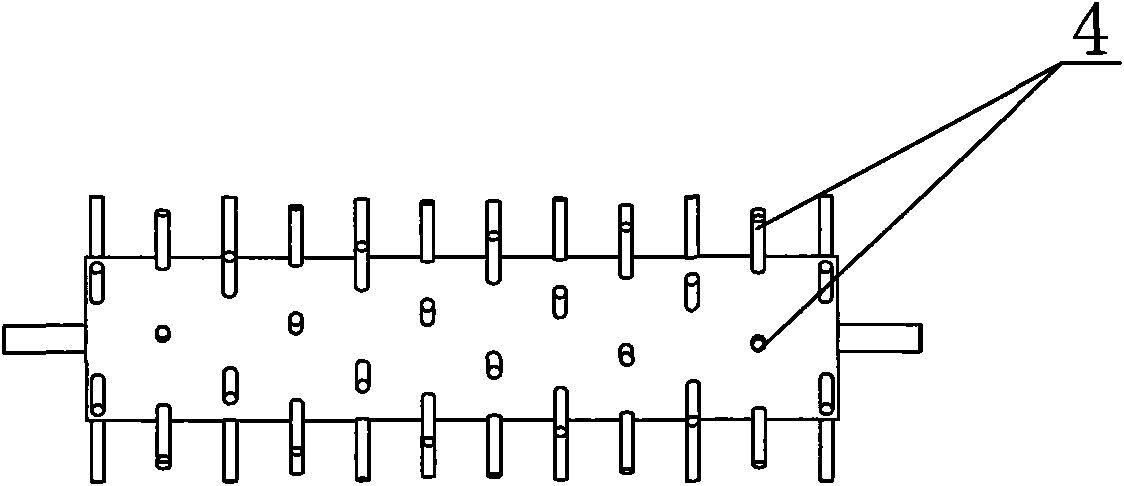

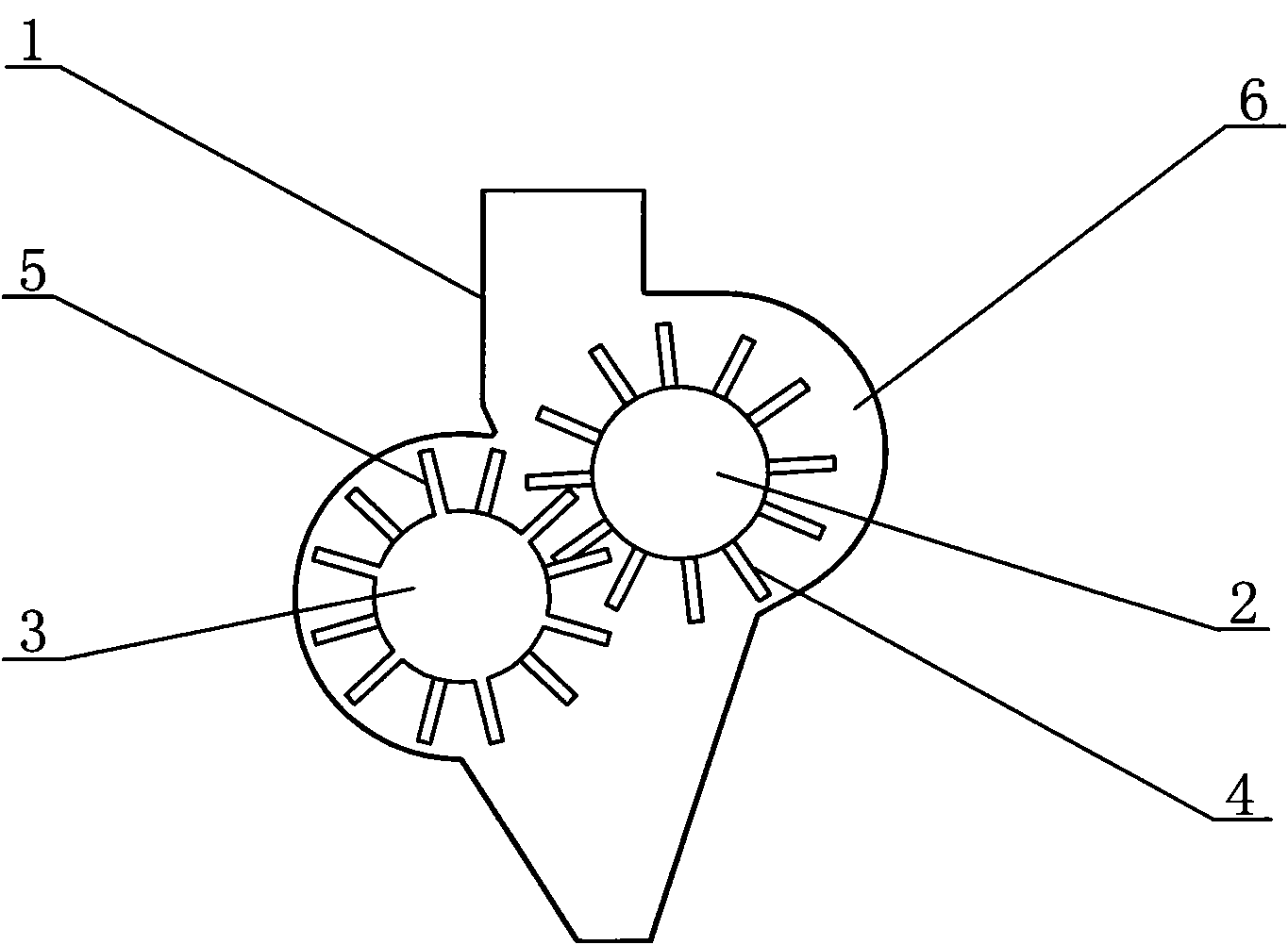

[0016] As shown in the figure, the seed cotton opening device of the seed cotton foreign fiber removal machine is provided with a casing 1, the upper and lower ends of the casing 1 are open, and the seed cotton flows in from the upper end of the casing 1 and flows out from the lower end. There are feeding roller 2 and opening roller 3 inside the casing 1, and the feeding roller 2 is arranged obliquely above the opening roller 3 at an angle of 25°-50°, that is, from the center of the feeding roller 2 to the opening roller The connecting line of the 3 centers forms an angle of 25°-50° with the horizontal direction. Feeding rods 4 are evenly distributed on the feeding roller 2, and opening rods 5 are evenly distributed on the opening roller 3, and the feeding rods 4 and the opening rods 5 are interlaced. In order to improve the opening efficiency and quality, the feeding rods 4 on the feeding roller 2 are distributed helically along the axial direction of the roller body, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com