Novel method for processing soft soil subgrade by pile-supporting reinforcing technology

A technology for technical treatment and soft soil roadbed, which is applied in the new pile-supported reinforcement technology to treat soft soil roadbed and the field of soft foundation treatment under high fill embankment, which can solve the problem of large settlement and uneven settlement, and insignificant effect of tensioned membrane. , the high cost of laying the sand cushion layer, etc., to achieve the effect of reducing uneven settlement, improving the effect of tension film, and improving the stability of the roadbed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The method of the present invention will be further described in detail below in conjunction with specific embodiments:

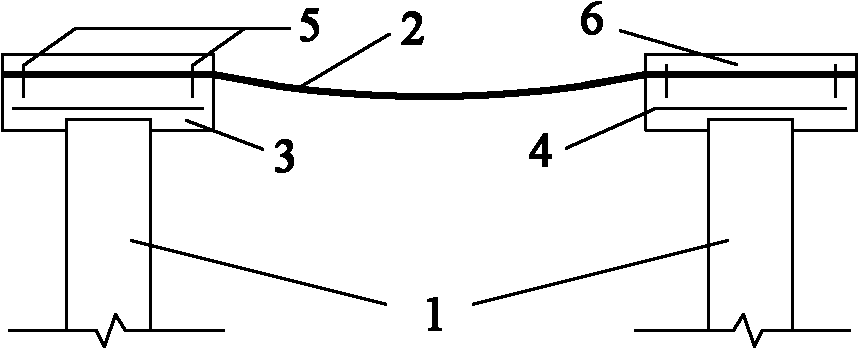

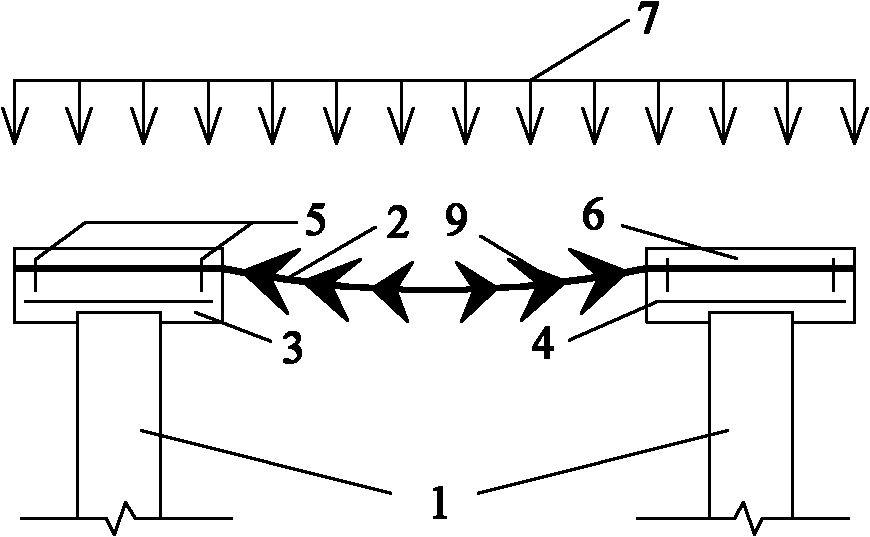

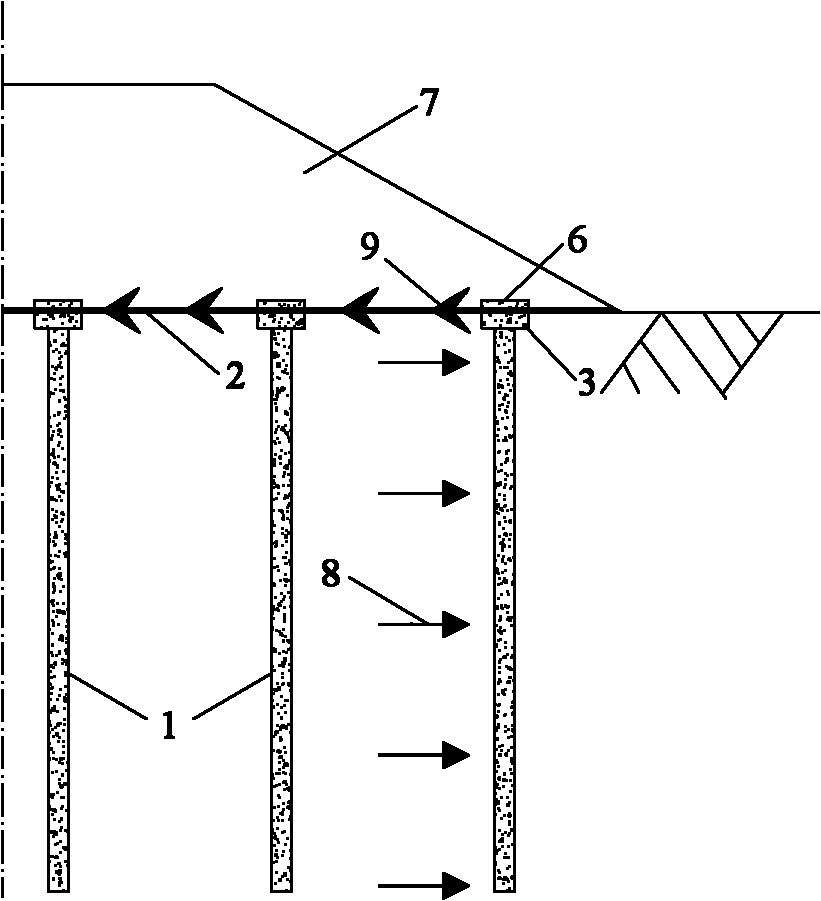

[0035] according to figure 1 It can be seen that a new method of pile-supported reinforcement technology for soft soil roadbed treatment, its steps are:

[0036] A. Drive pile 1 into the foundation to be reinforced, the elastic modulus of the pile body is 10 GPa, the pile 1 is bored pile 1, the diameter of pile 1 is 500 mm, and the length of pile 1 is 10m. Should fall into the bearing layer, the spacing between pile 1 is 3.5m, and square piles shall be used;

[0037] B. Support formwork on top of pile 1, and cast in-situ reinforced concrete pile cap 3. The pile cap 3 is square with a side length of 1000 mm. The thickness of the pile cap 3 is 250 mm, and the steel mesh 4 is arranged in two-way uniform length with a diameter of 6 mm and a spacing of 100 mm. The concrete strength grade is C25, the thickness of the protective layer of the steel mesh 4 is 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com