Construction method for variable-section composite pile

A construction method and variable cross-section technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high cost, waste of resources, high pile replacement rate, etc., and achieve convenient construction, lower project cost, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

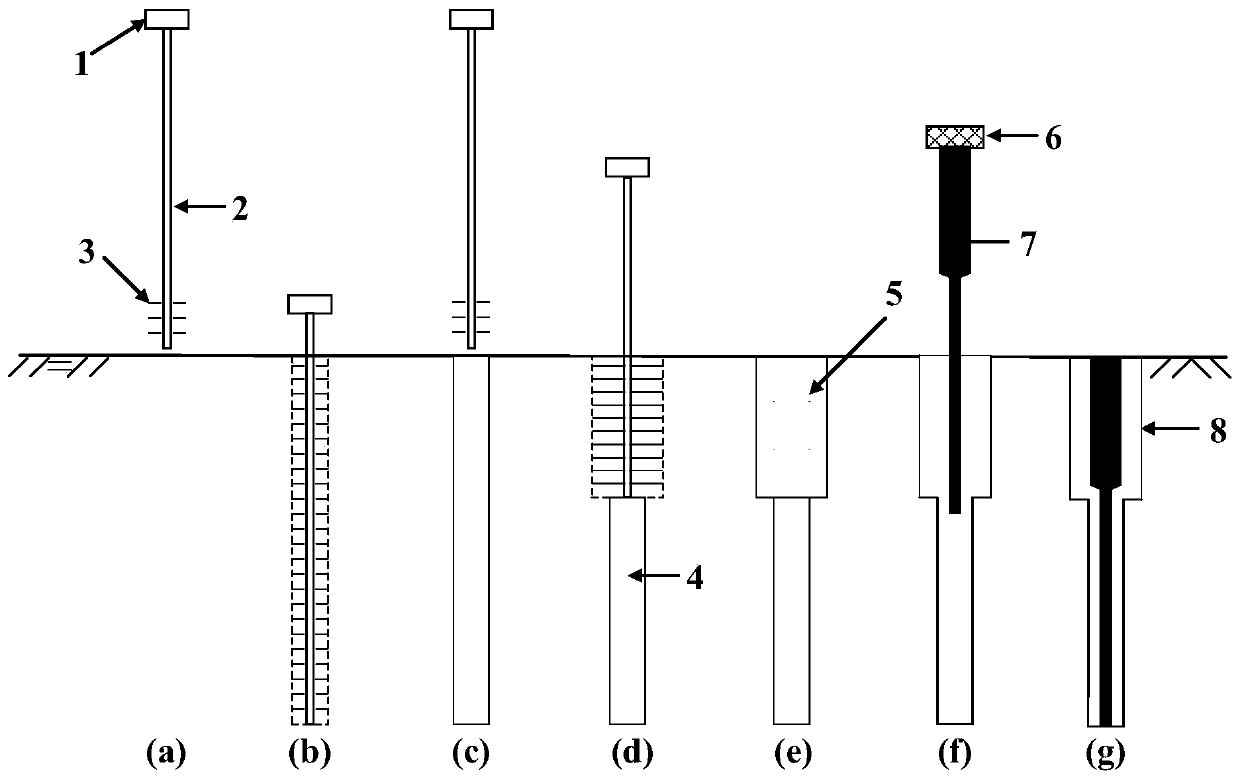

[0028] Variable section composite pile of the present invention and construction method thereof, such as figure 1 shown. Include the following steps:

[0029] a. Leveling the site and positioning of the two-way mixing pile machine: the pile positions of the variable-section cement-soil mixing piles are arranged in a plum blossom shape or a square; use a crane to suspend the two-way mixer to the designated pile position and perform alignment;

[0030] b. Drilling down, grouting, mixing: Start the drill pipe and the pressurizing device in turn, the pressurized drill pipe drills down along the guide frame, and the mixing blade is extended to 800mm (the common diameter of the lower part of the variable cross-section mixing pile 800 ~ 1200mm, this embodiment selects 800mm pile diameter), when the bottom rotating blade of the drill bit at the end of the drill pipe finishes cutting and entering the soil, the spraying device is turned on, the middle rotating blade stirs, and the top ...

Embodiment 2

[0037] A variable section composite pile and its construction method, such as figure 1 shown. Include the following steps:

[0038] a. Leveling the site and positioning of the two-way mixing pile machine: the pile positions of the variable-section cement-soil mixing piles are arranged in a plum blossom shape or a square; use a crane to suspend the two-way mixer to the designated pile position and perform alignment;

[0039] b. Drilling down, grouting, mixing: Start the drill pipe and the pressurizing device in turn, the pressurized drill pipe drills down along the guide frame, and the mixing blade is extended to 800mm (the common diameter of the lower part of the variable cross-section mixing pile 800 ~ 1200mm, this embodiment selects 800mm pile diameter), when the bottom rotating blade of the drill bit at the end of the drill pipe finishes cutting and entering the soil, the spraying device is turned on, the middle rotating blade stirs, and the top rotating blade presses the ...

Embodiment 3

[0046] A variable section composite pile and its construction method, such as figure 1 shown. It is characterized in that it comprises the following steps:

[0047] a. Leveling the site and positioning of the two-way mixing pile machine: the pile positions of the variable-section cement-soil mixing piles are arranged in a plum blossom shape or a square; use a crane to suspend the two-way mixer to the designated pile position and perform alignment;

[0048] b. Drilling down, grouting, mixing: Start the drill pipe and the pressurizing device in turn, the pressurized drill pipe drills down along the guide frame, and the mixing blade is extended to 800mm (the common diameter of the lower part of the variable cross-section mixing pile 800 ~ 1200mm, this embodiment selects 800mm pile diameter), when the bottom rotating blade of the drill bit at the end of the drill pipe finishes cutting and entering the soil, the spraying device is turned on, the middle rotating blade stirs, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com