Micro channel heat exchanger for air-conditioner heat pump

A micro-channel heat exchanger, heat exchanger technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of increasing the air side flow resistance, reducing the heat transfer coefficient of the heat exchanger, reducing the problems such as the heating capacity of the unit, to achieve the effects of reducing wind resistance, improving frost formation, and improving emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention. In the drawings, components with the same reference numerals represent the same or similar components.

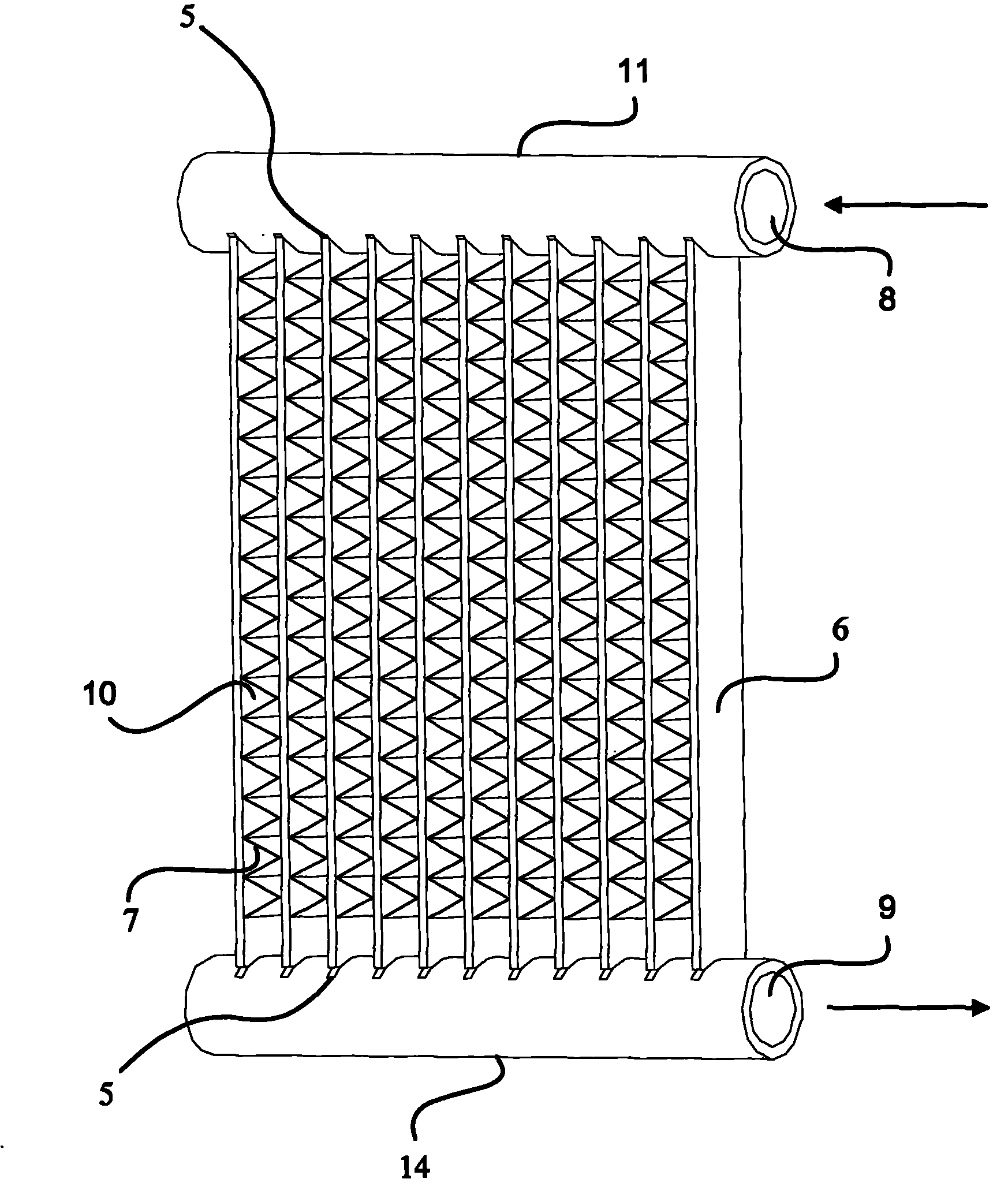

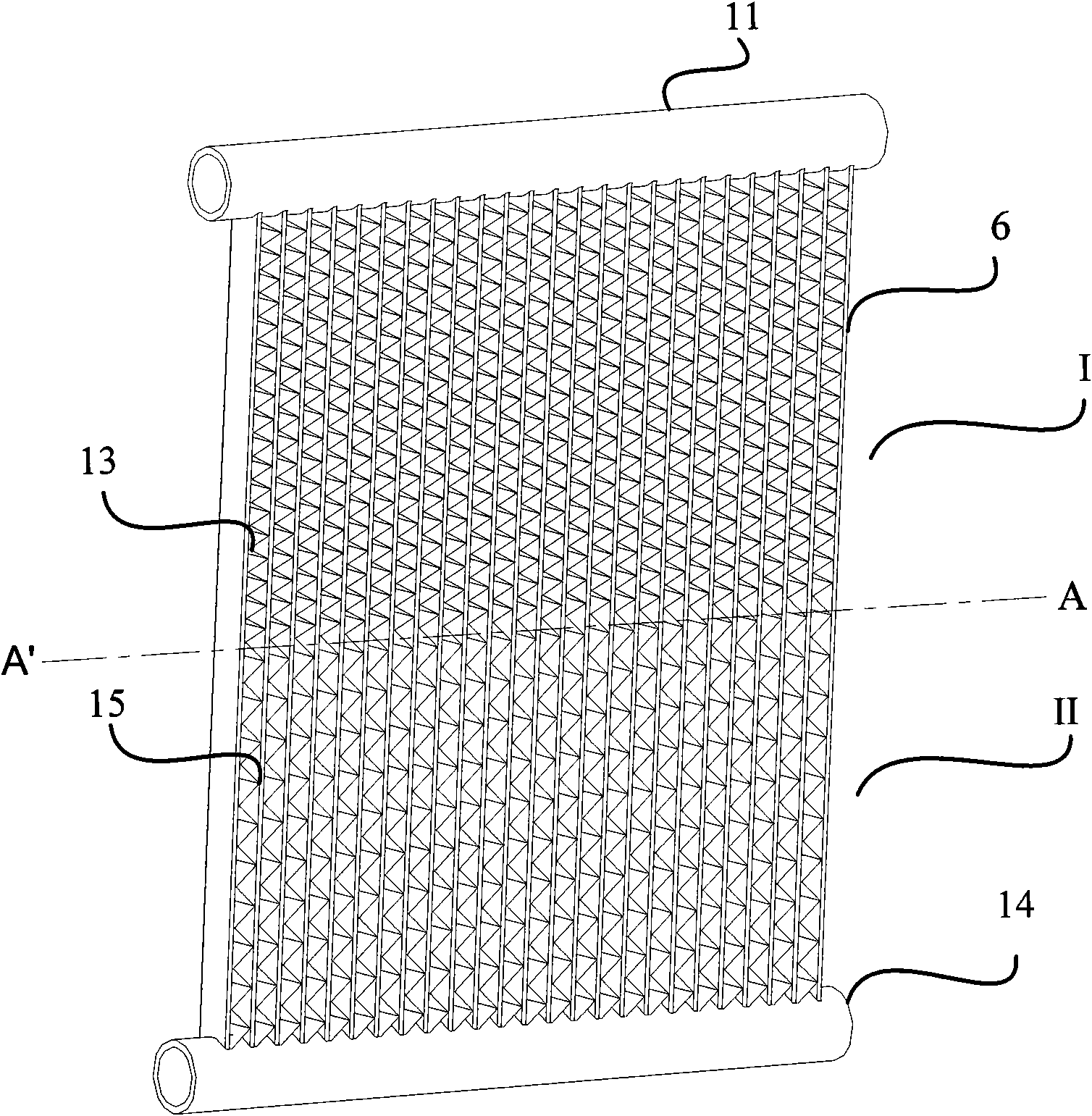

[0041] refer to Figure 3a and Figure 3b as shown, Figure 3a shows a schematic structural view of a heat exchanger according to the present invention, Figure 3b for Figure 3a Schematic diagram of the distribution of fins in regions I and II in the middle part. The heat exchanger according to this embodiment comprises: an upper head pipe 11, a lower head pipe 14 parallel to the upper head pipe 11, a plurality of separated parallel flat pipes 6 connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com