Time sequence control circuit and control method thereof

A timing control circuit and control circuit technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve the problems of complex process, high chip manufacturing cost, permanent chip damage, etc., and achieve simple process, The effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

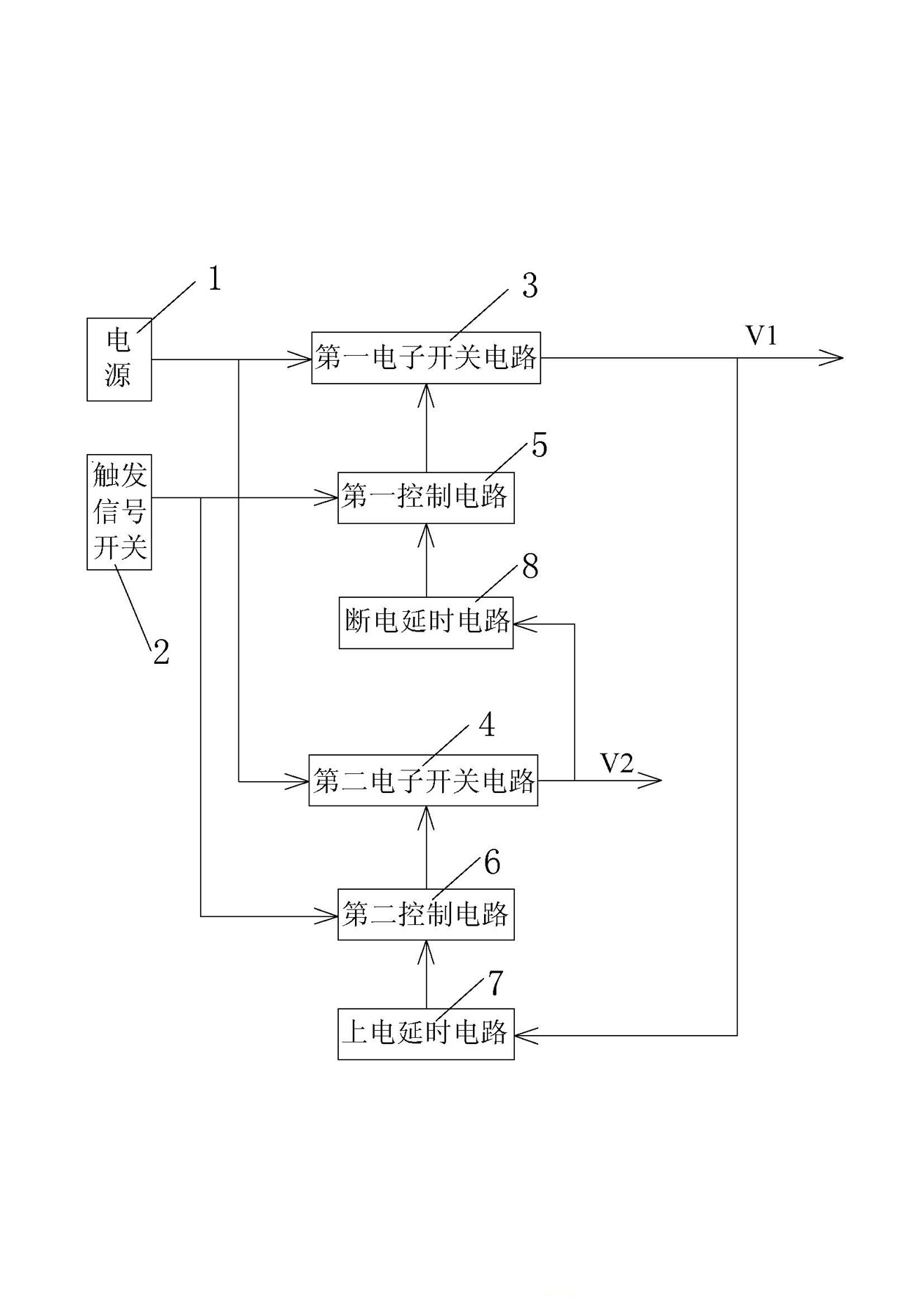

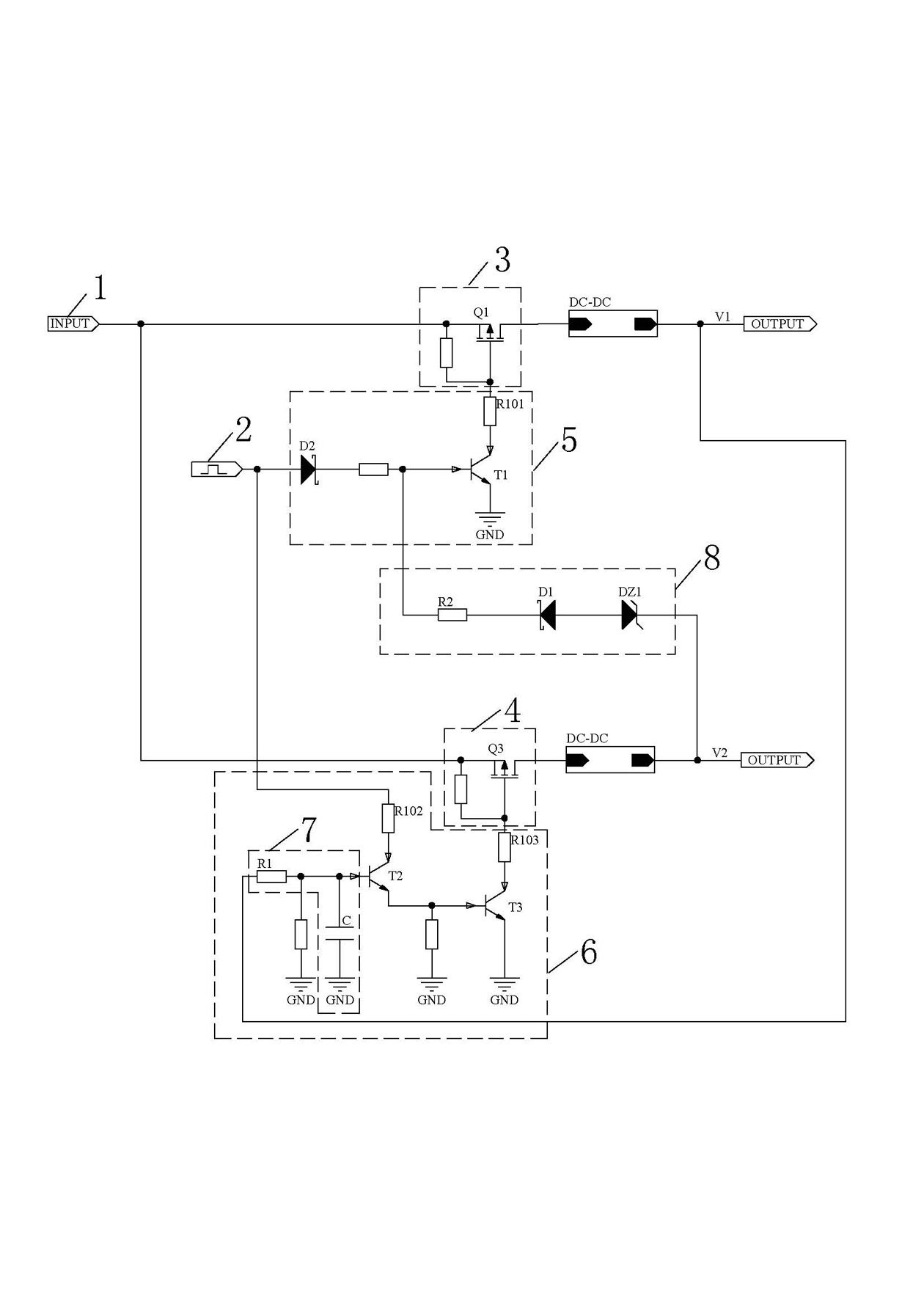

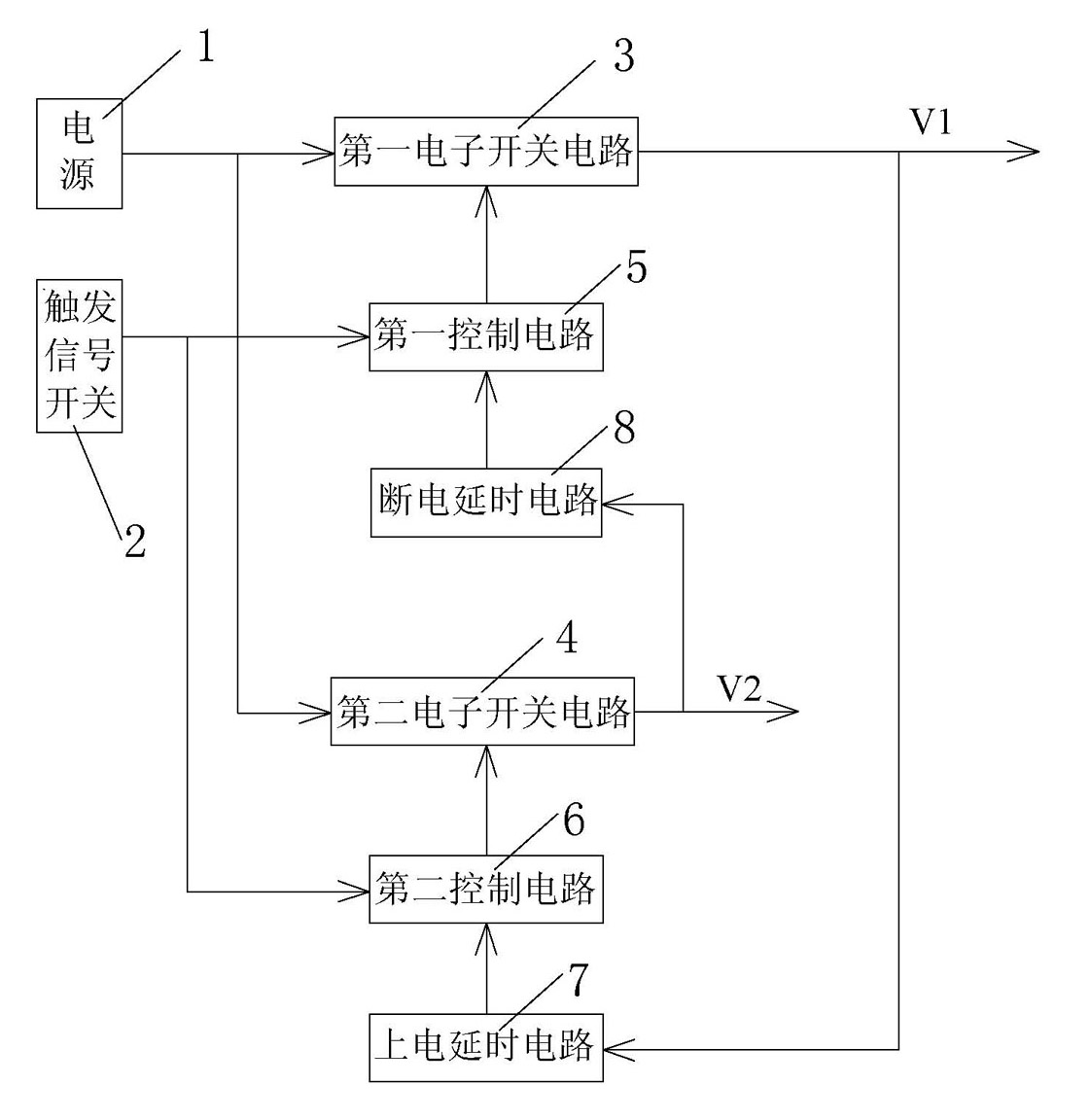

[0022] refer to figure 1 , a timing control circuit of the present invention, comprising a power supply 1, a trigger signal switch 2, a first electronic switch circuit 3 connected in series between the power supply 1 and the first voltage output terminal V1, and connected in series between the power supply 1 and the second voltage output terminal The second electronic switch circuit 4 between V2, the first control circuit 5 connected between the trigger signal switch 2 and the first electronic switch circuit 3, the first control circuit 5 connected between the trigger signal switch 2 and the second electronic switch circuit 4 Two control circuits 6, RC power-on delay circuit 7 and power-off delay circuit 8; wherein, the RC power-on delay circuit 7 is connected between the first voltage output terminal V1 and the input terminal of the second control circuit 6 , the power-off delay circuit 8 is connected between the second voltage output terminal V2 and the input terminal of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com