Floating grid modulator

A floating gate and modulator technology, applied in the electronic field, can solve problems such as inability to miniaturize integration, increase circuit loss, and misoperation of switching tubes, etc., to reduce common conduction time, reduce cost and volume, and reduce circuit loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and examples.

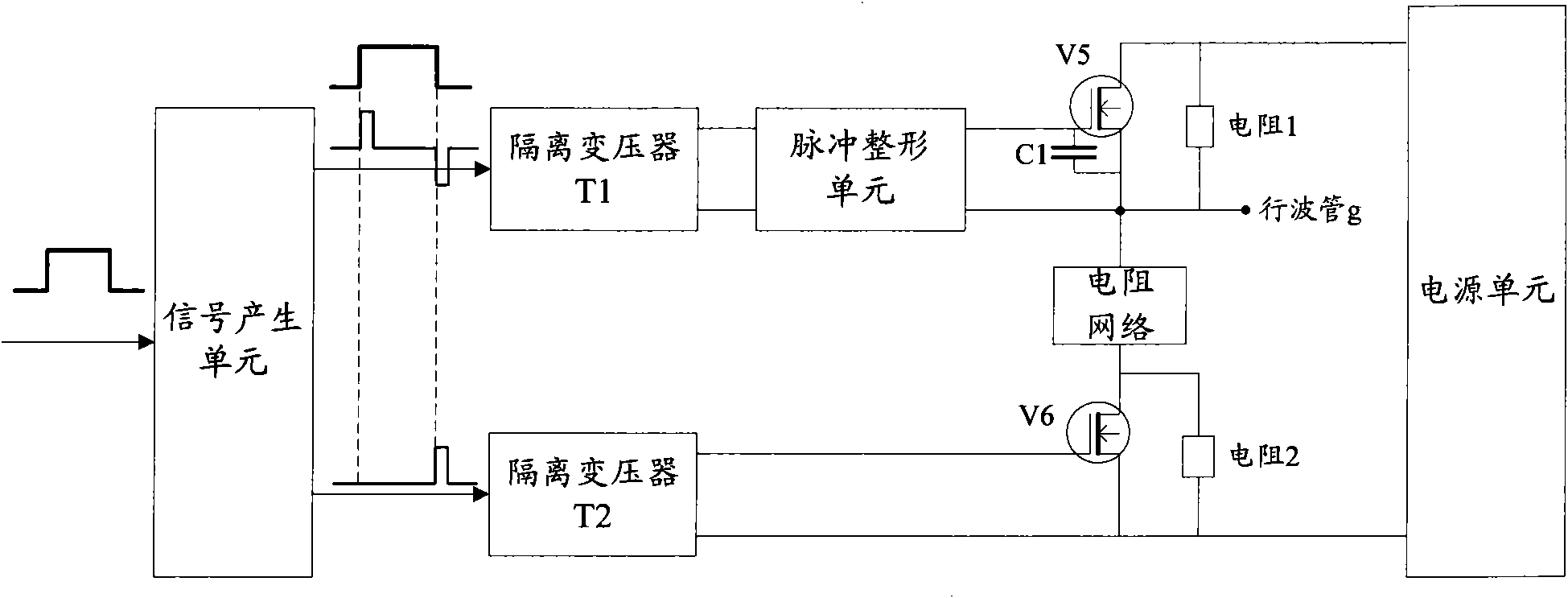

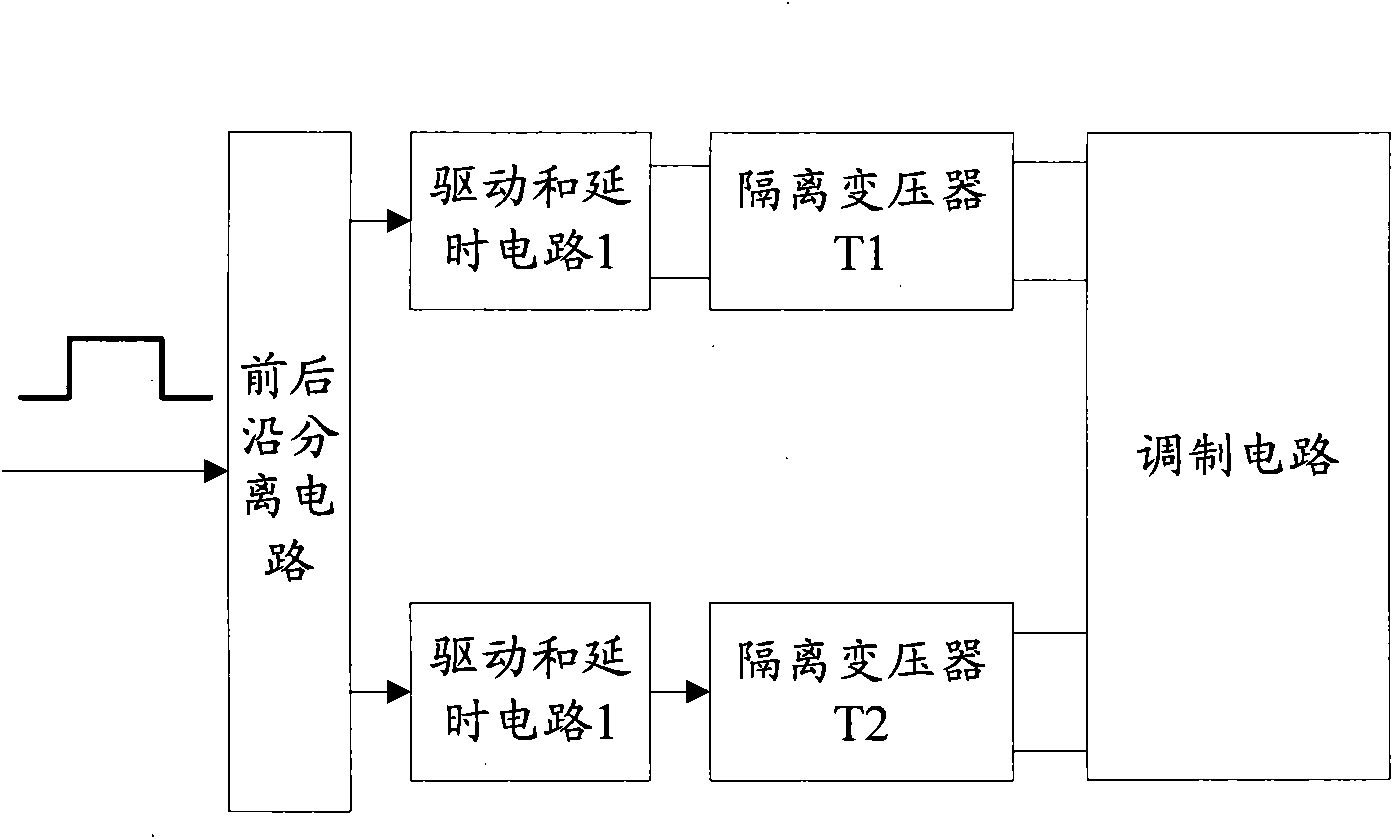

[0041] figure 2 It is a structural block diagram of the floating gate modulator of the present invention. like figure 2 As shown, the floating gate modulator includes: front and rear edge separation circuit, drive and delay circuit 1, drive and delay circuit 2, isolation transformer T1, isolation transformer T2 and modulation circuit; wherein,

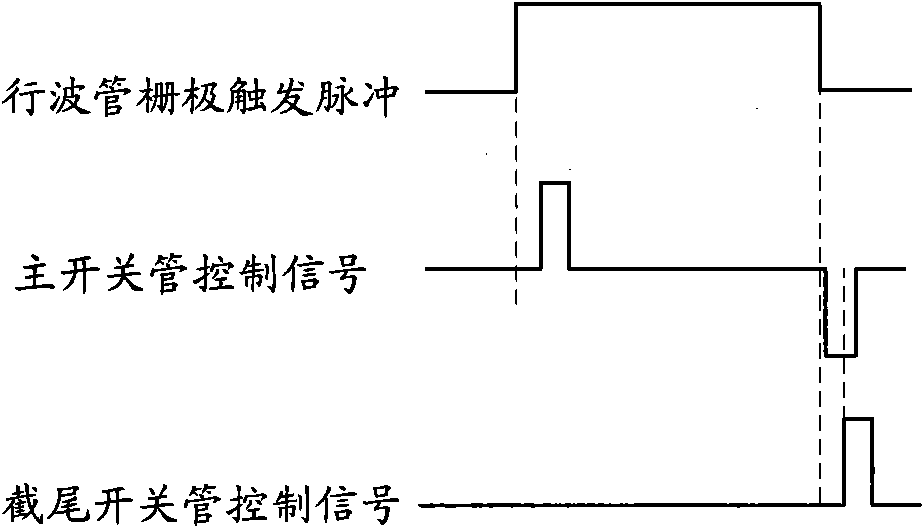

[0042] The front and rear edge separation circuit extracts the front and rear edges of the trigger pulse from the trigger pulse of the TWT gate to form the front negative pulse signal and the rear negative pulse signal; the front negative pulse signal and the rear negative pulse signal are used as the main switching tube The control signal is input to the drive and delay circuit 1, and the trailing edge negative pulse signal is input to the drive and delay circuit 2 as the control signal of the truncated switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com