Circular tomosynthesis x-ray tube

A technology of X-ray tube and X-ray, applied in the field of X-ray tube and X-ray inspection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

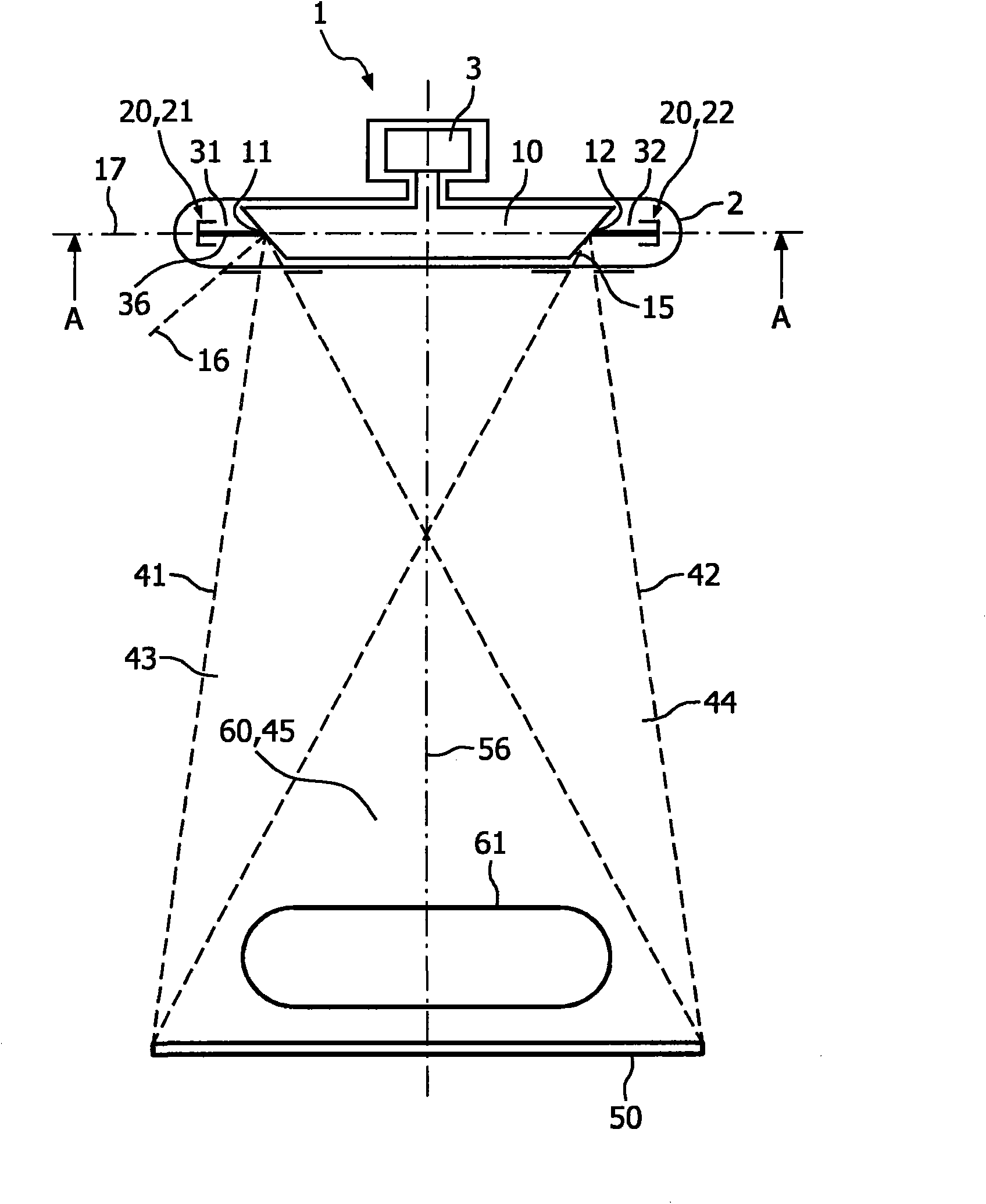

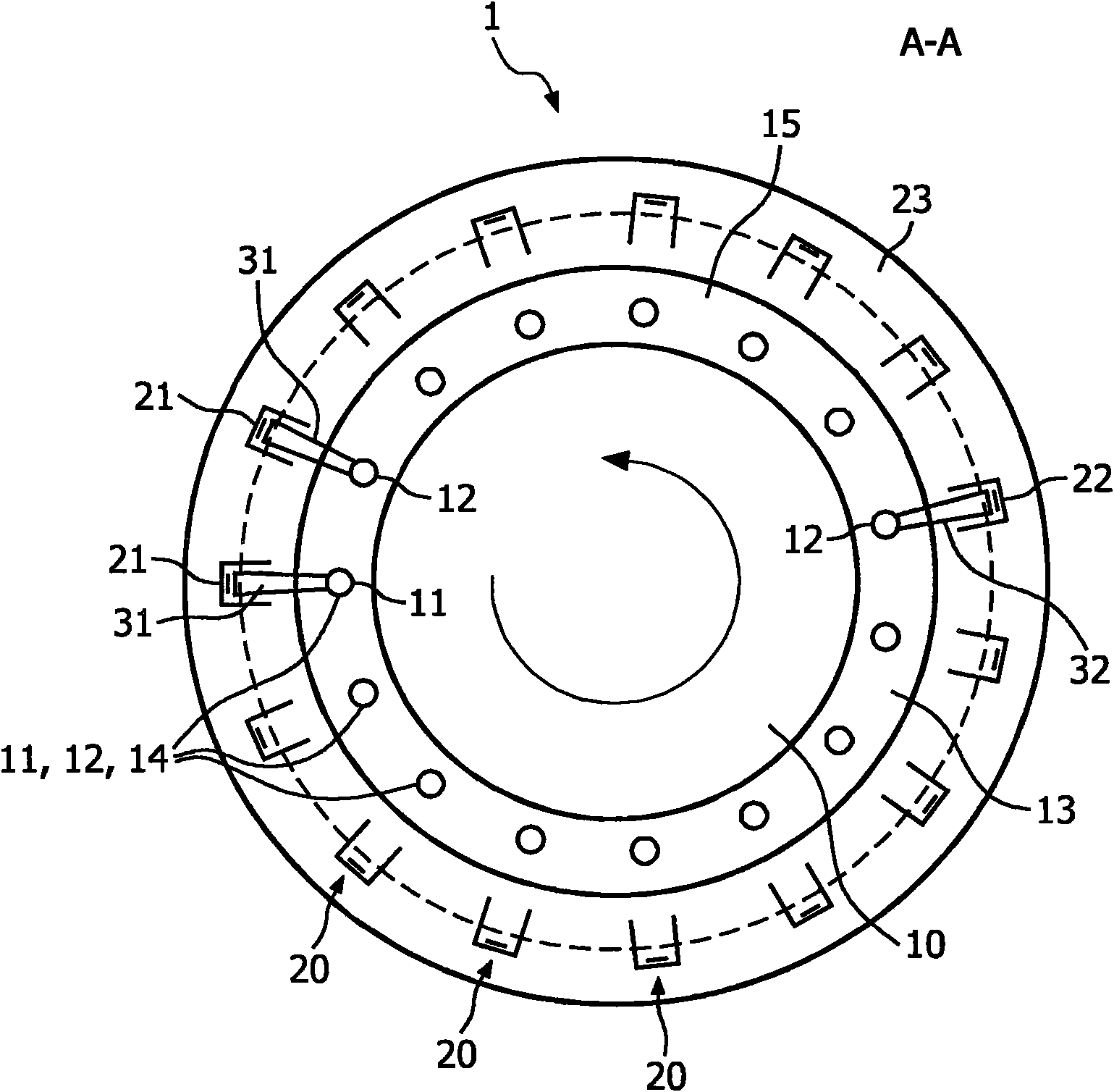

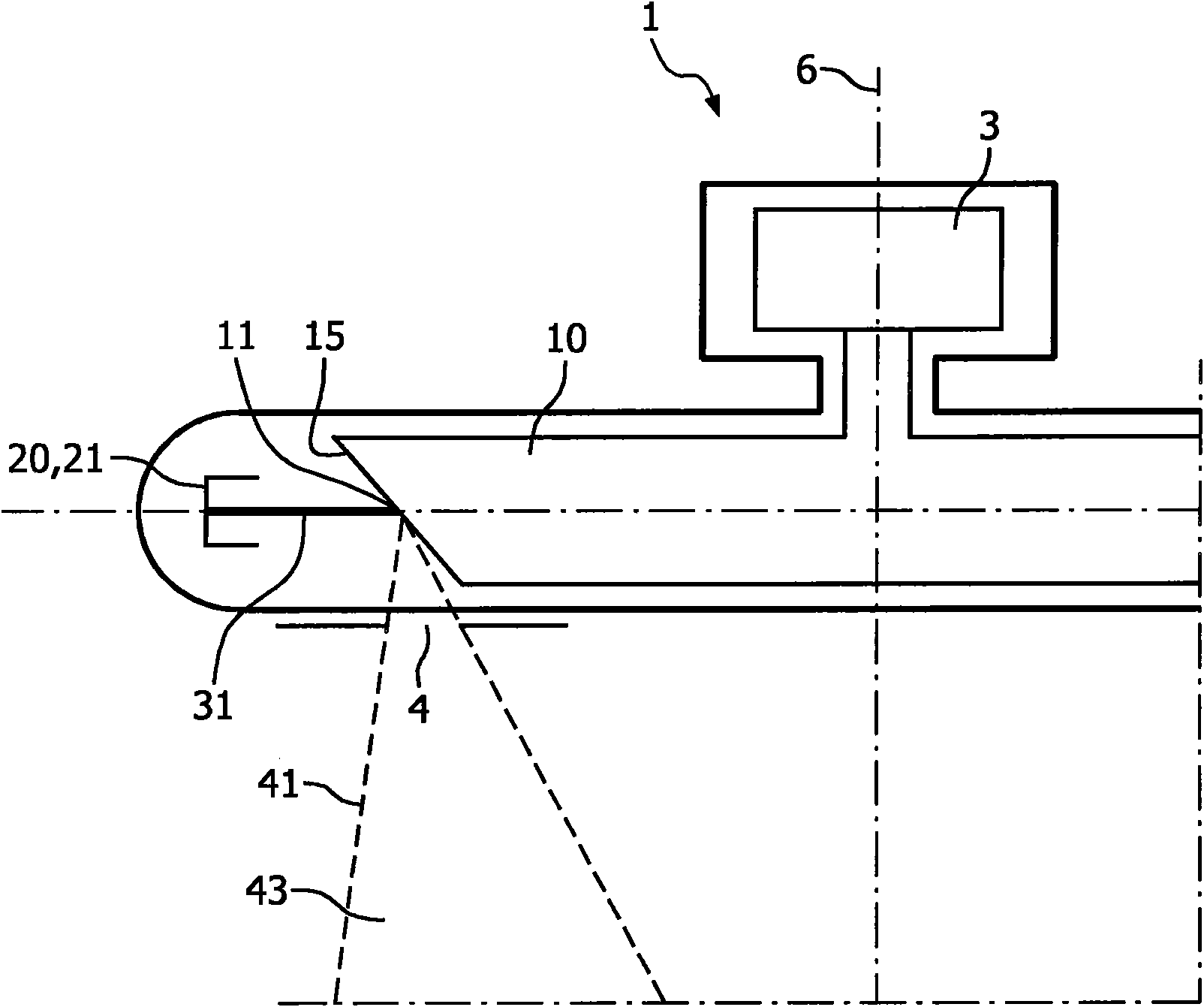

[0054] figure 1 An X-ray tube 1 is shown in the figure. An anode arrangement 10 is provided in the housing 2 of the x-ray tube 1 , which can be rotated by the electric motor 3 in order to avoid damage to the path of the focal spot. The anode arrangement 10 may be provided with a plurality of focal spot positions 11, 12, however, the focal spot positions do not necessarily correspond to fixed positions on the anode surface since the surface of the anode 10 may rotate during operation. The focal spot positions 11, 12 should be considered to be the respective positions where the electron beams 31, 32 encounter the anode arrangement. It should be noted that the anode arrangement 10 can also be provided with a larger number of focal spots or focal spot positions. Inside the housing 2 there is also a cathode arrangement 20 having a plurality of electrodes including a first cathode 21 and a second cathode 22 . It should also be noted that the number of cathodes and focal spot posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com