Purification workshop

A technology for purifying workshops and houses, applied in the structural field of workshops, can solve the problems of large number of wind cabinets, return air ducts and air supply ducts, consumption of electric energy and steel, etc. The effect of uniform and stable wind and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

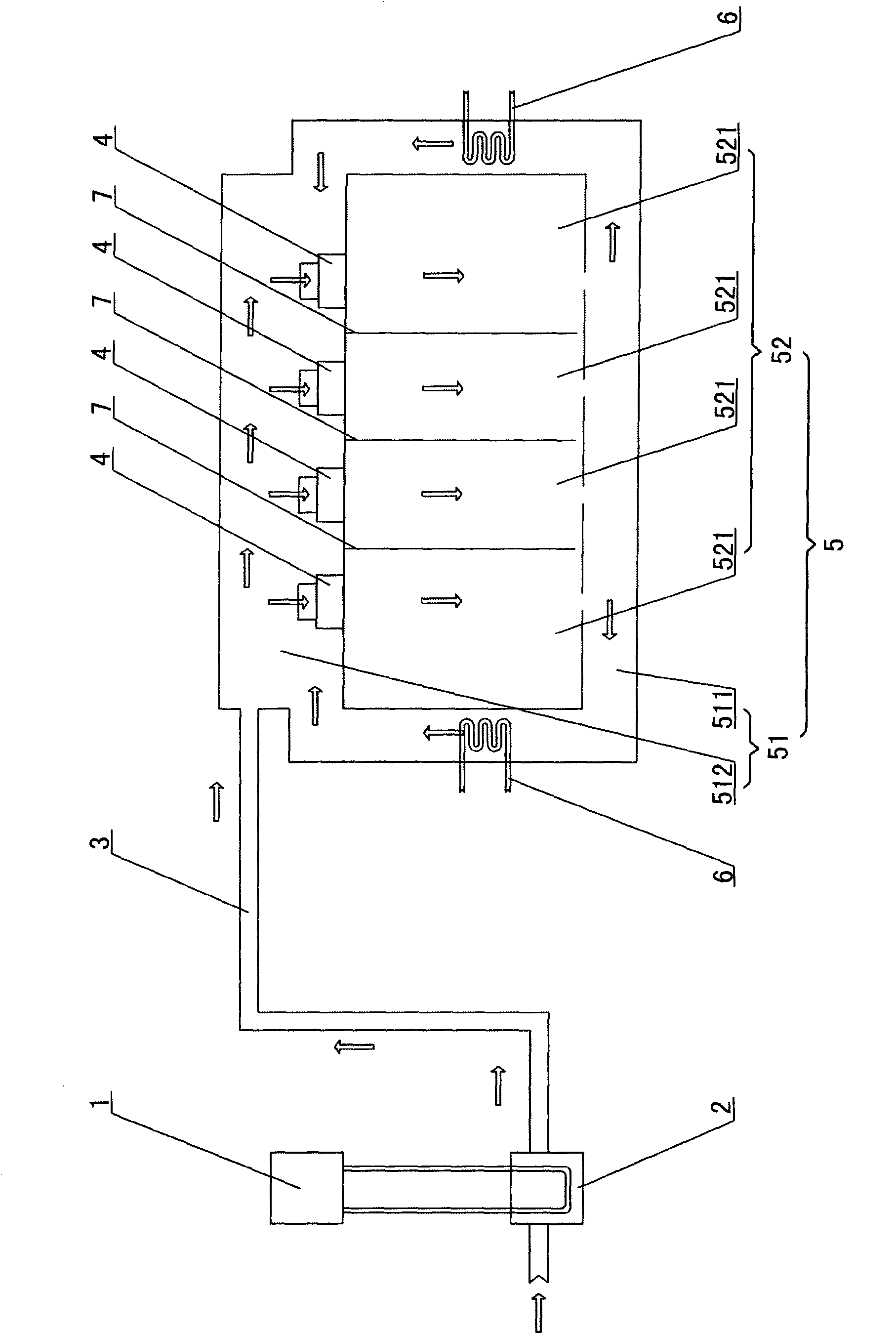

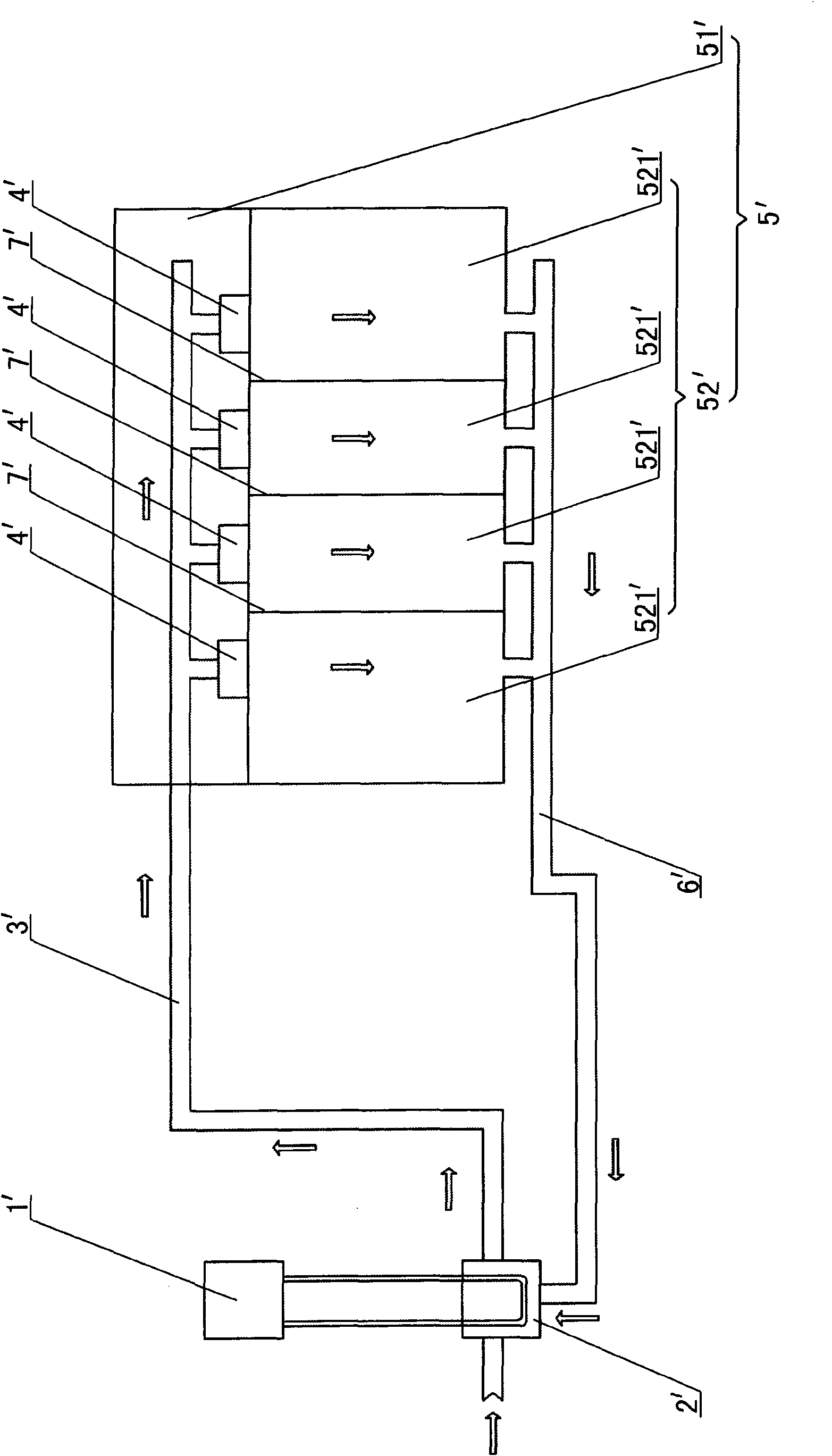

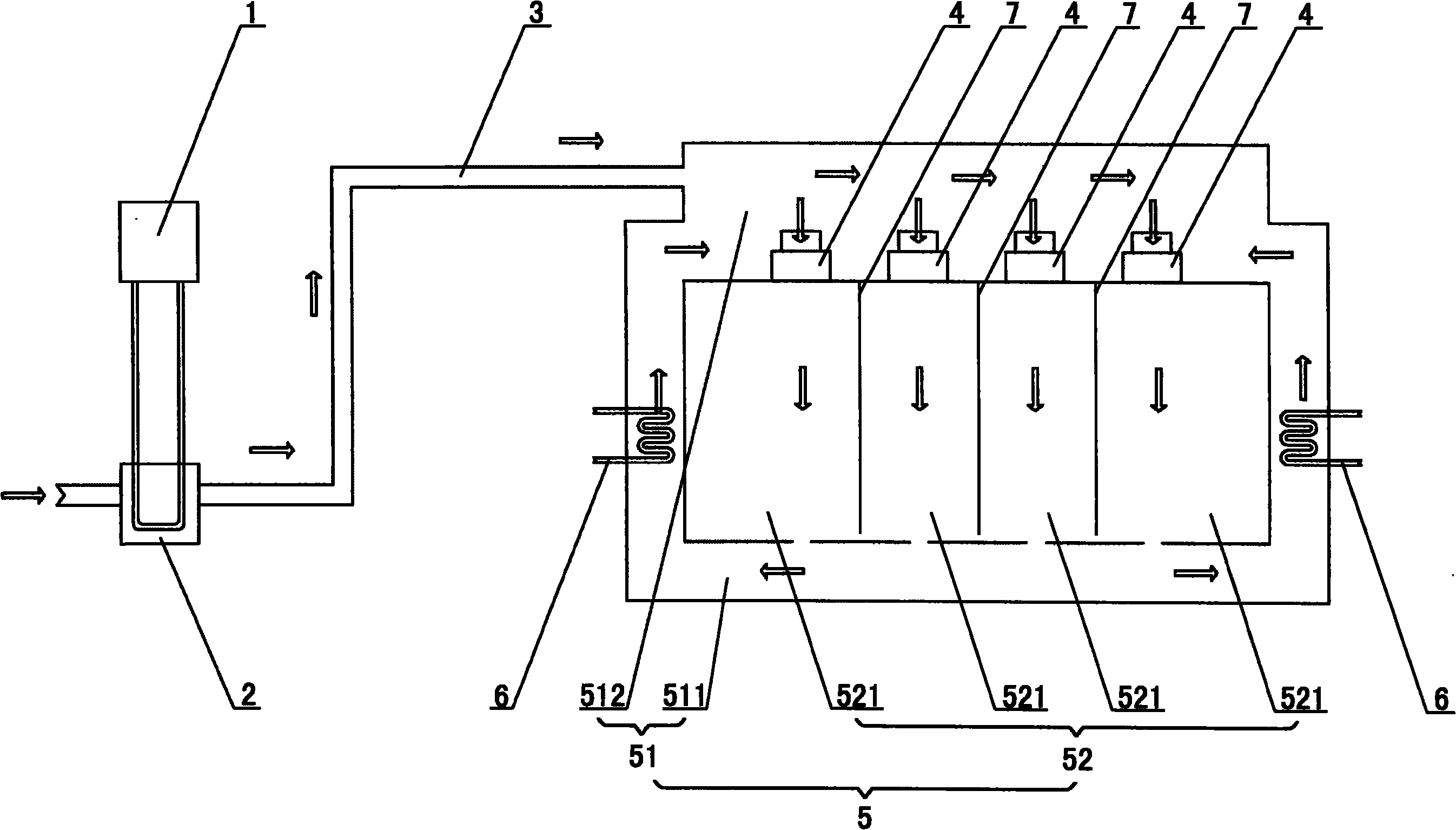

[0022] Such as figure 1 As shown, the purification plant in this preferred embodiment includes a room body 5 and an air supply system. The interior space of the room body 5 includes a work space 52 and a circulating air supply space 51 around the work space 52. The circulating air supply space 51 includes The air return area 511 and the static pressure area 512 above the working space 52 have multiple air inlets on the top and multiple air outlets on the bottom of the working space 52 . The air supply system comprises a cooling device 1, an air cabinet 2, an air supply duct 3 and a plurality of fan filter units 4 (FFUs). In the static pressure area 512, each air inlet is provided with a fan filter unit 4. That is to say, the number of the air inlets is the same as the number of the fan filter unit 4, and they are in one-to-one correspondence.

[0023] The return air area 511 is also provided with a plurality of return air cooling devices 6 . The return air cooling device 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com