Miniature air pump and one-way valve for same

A technology of one-way valve and air pump, which is applied in the direction of pump components, variable capacity pump components, liquid variable capacity machines, etc., can solve the problems of high processing requirements for structural parts, damage to sealing effect, damage to sealing effect, etc., and achieve the goal of using Long life, simplified structure, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

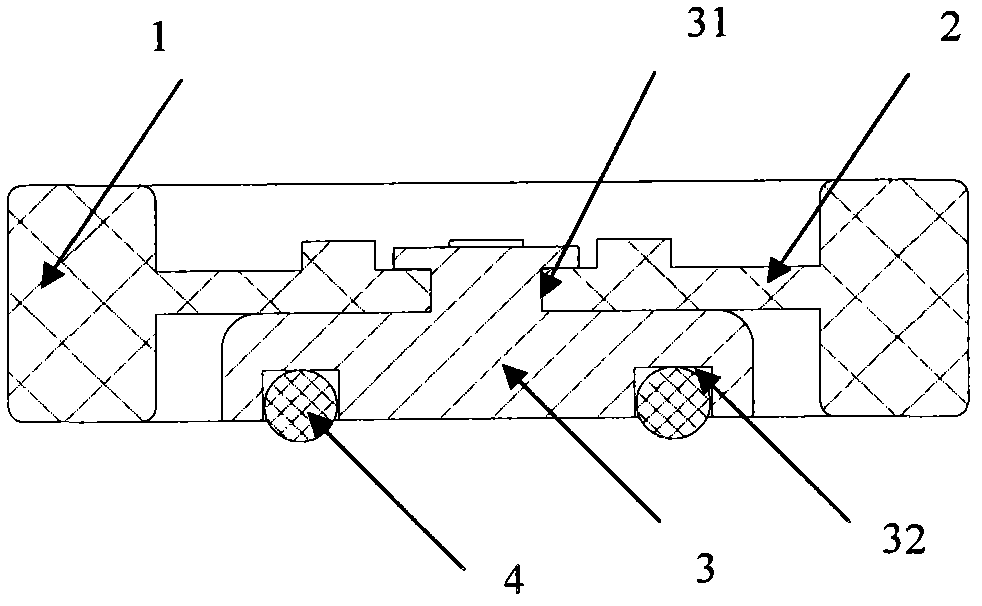

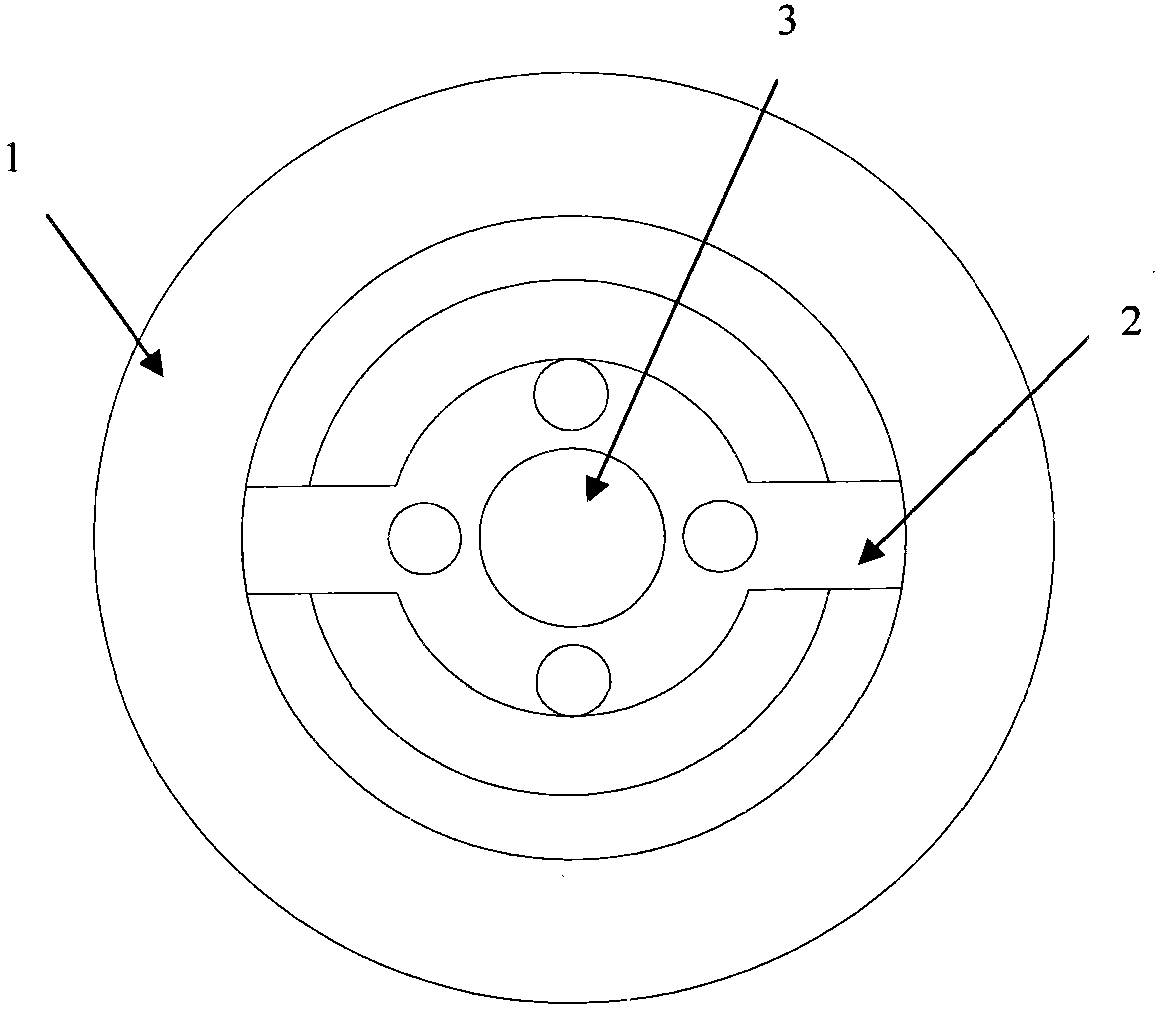

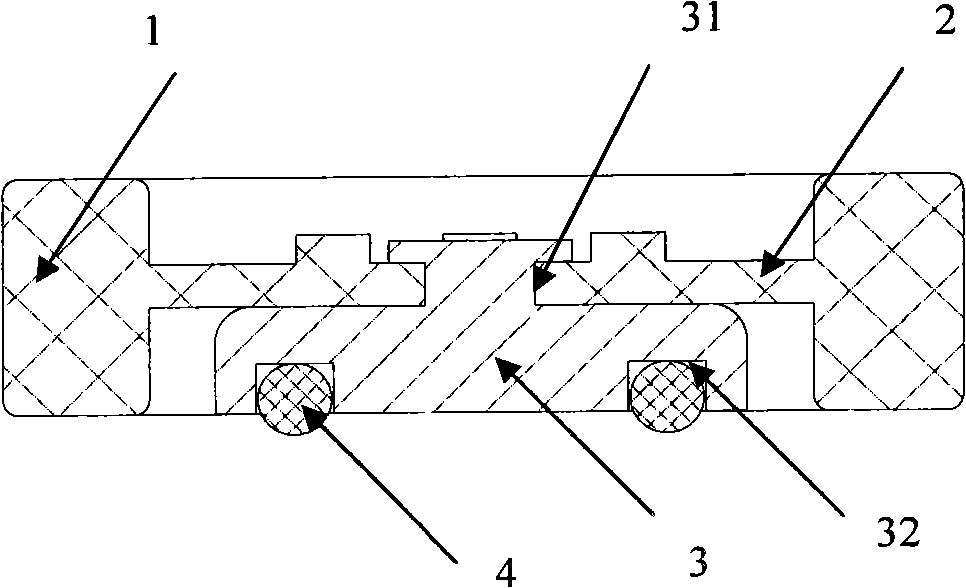

[0014] The one-way valve of the present invention includes a cavity seal 1, an elastic arm 2, a metal gasket 3 and a sealing ring 4, wherein the cavity seal 1 is an annular structure, which is the external support and seal of the entire structure, and is installed on two valves that need to be sealed. Between the planes, a sealed cavity is formed, which is also used as the seal of the overall structure, and is made of elastic material; the elastic arm 2 is a strip structure extending inward from the cavity seal 1, and can be stretched by using the elasticity of the rubber. 2. The lower part is connected with the upper part of the cavity seal 1; the metal pad 3 is disc-shaped, and the upper annular slot 31 is used to insert the elastic arm 2 so that it is stuck in the slot 31 and connected with the upper part of the metal pad 2. The metal pad The bottom of 3 is provided with an annular groove 32, and sealing ring 4 is placed in it;

[0015] After the present invention is assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com