Integrated safety valve for high-pressure air long-tube semi-trailer

A high-pressure gas and semi-trailer technology, applied in safety valves, gas/liquid distribution and storage, valve details, etc., can solve the problems of processing troubles, reduce the processing efficiency of end plugs, etc., and achieve high processing efficiency and high vehicle assembly efficiency , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

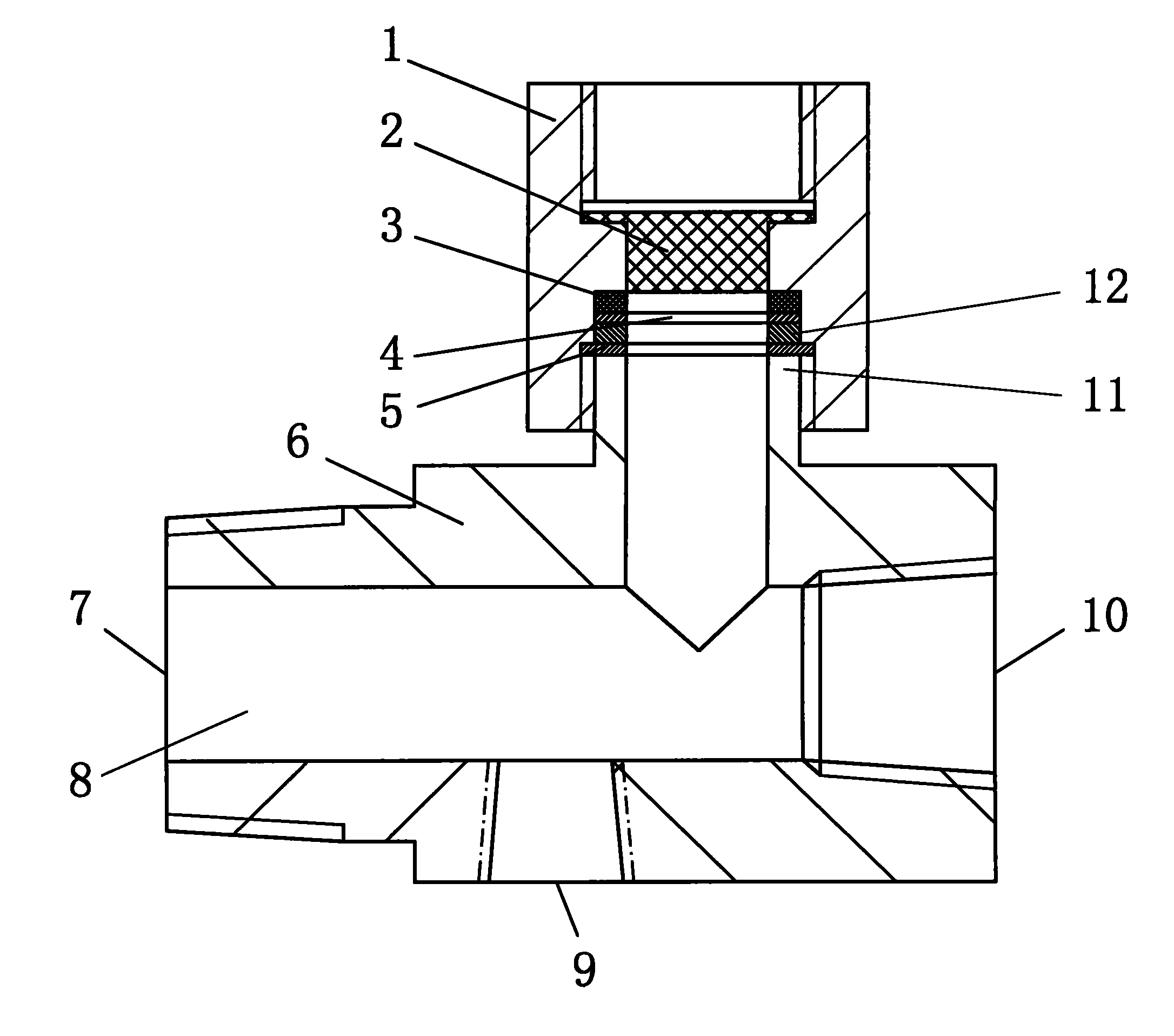

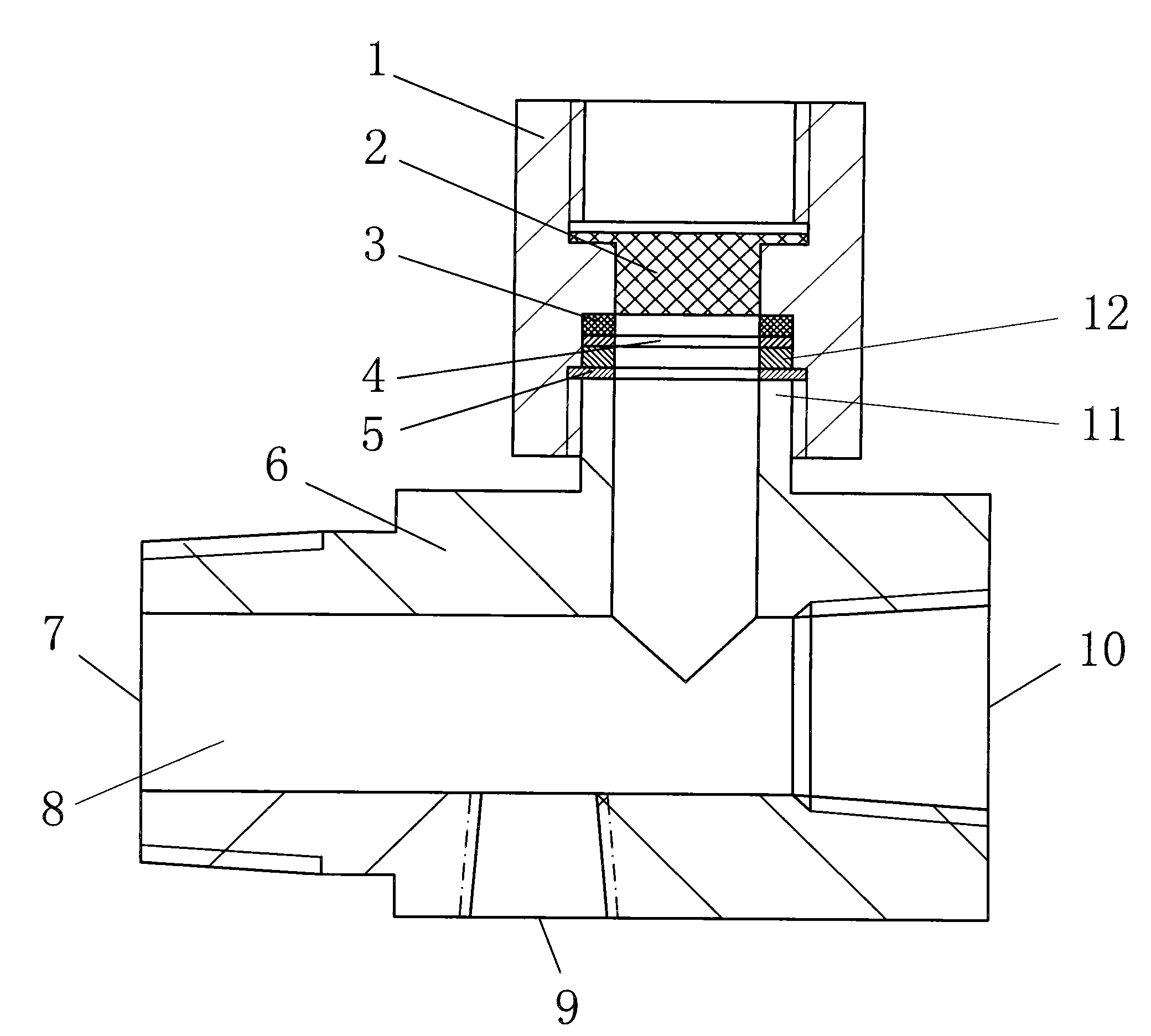

[0012] As shown in the drawings, the valve body 6 has an inner hole 8 with a diameter of Φ25mm. One end of the valve body 6 is an air inlet and a blowdown port 6, and an NPT1.5 "outer pipe thread is arranged on the air inlet and a blowdown port 6. The air inlet and blowdown port 6 is sealed and connected with the air inlet and the blowdown port of the high-pressure gas cylinder. The other end of the valve body 6 is a sewage discharge interface 10, and the sewage discharge interface 10 has internal pipe threads, and the sewage discharge interface 10 is sealed and connected with the sewage discharge port of the high-pressure gas cylinder; 8 connected to the emptying interface 11, the emptying interface 11 has an external thread, and the compression nut 1 is screwed on the external thread, and the spacer 5, Inner clamping ring 12, bursting disc 4, outer clamping ring 3 and soluble alloy 2. There is also an air inlet and outlet port 9 on the cylindrical surface of the valve body 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com