Simulation test bed for automatic gearbox controller

An automatic gearbox and controller technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve the problems of inaccurate simulation of the working state of the gearbox, time-consuming and labor-intensive simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

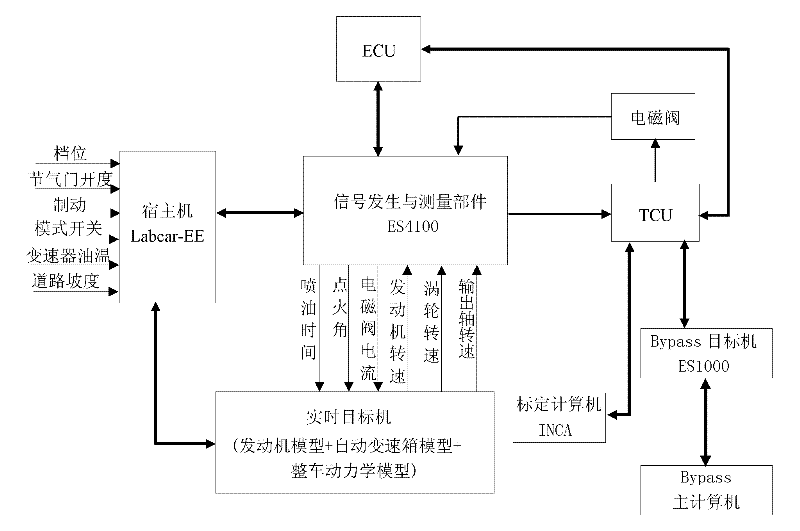

[0037] An embodiment of the automatic transmission controller simulation test bench of the present invention is as follows: figure 1 As shown, it includes a host machine, a real-time target machine, a signal generation and measurement component, an engine electronic controller, a plurality of solenoid valves, a calibration computer, a Bypass host computer, and a Bypass target machine;

[0038] Described host machine is provided with Labcar EE software (Labcar EE software is a kind of simulation environment setting software for Labcar real-time simulation platform, can carry out data interaction with connecting network host machine and target machine by it, can carry out model download, simulation condition setting and simulation result reading and display), automatic transmission vehicle powertrain simulation model, the simulation conditions include gear position, throttle opening, braking, transmission oil temperature, mode switch, road gradient, etc.; the host machine Connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com