Regulating control mechanism for high-vacuum oil filling equipment and oil filling speed regulating method thereof

A technology for regulating control and oil-filling equipment, which is applied in the flow control of auxiliary non-electric power, etc., can solve the problems of low oil-filling efficiency and inability to adjust the oil-filling speed in a small amount, and achieve high oil-filling efficiency, small footprint, The effect of guaranteeing purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

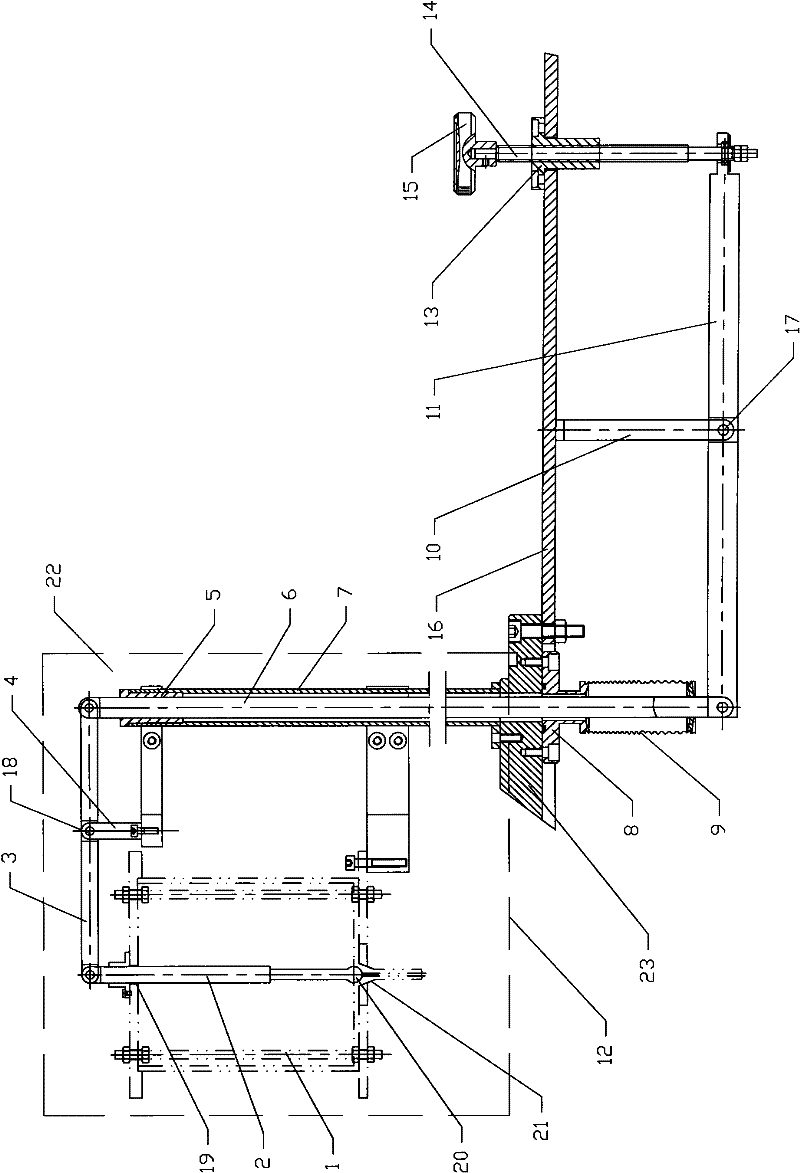

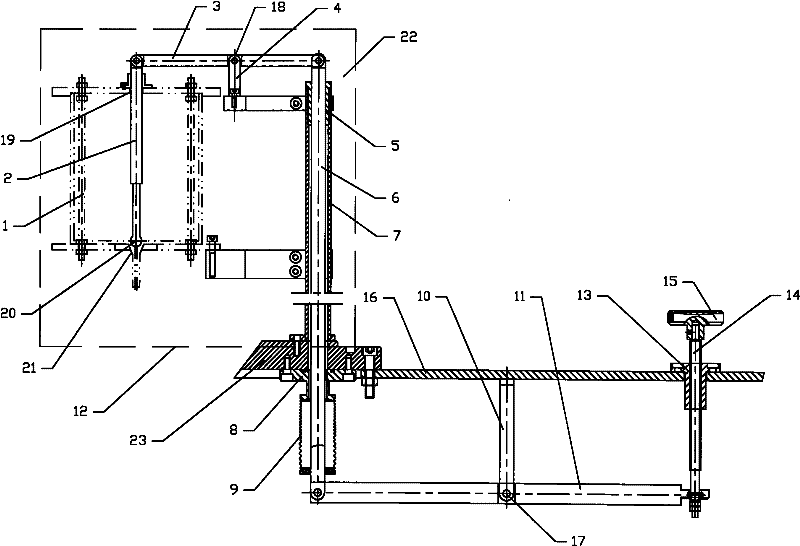

[0039] Such as figure 1 Shown is the preferred embodiment of the adjustment control mechanism for high vacuum oil-filled equipment of the present invention. The high vacuum oil-filled equipment includes common devices such as a vacuum chamber 22, an oil storage device, and a vacuum pumping device. Wherein, the vacuum chamber 22 includes a base plate 23 and a bell jar 12 placed on the base plate 23. In this embodiment, the bell jar 12 is a quartz bell jar. There is a sealing rubber ring, so that the vacuum chamber 22 can be sealed and evacuated; the oil storage device is an oil cup 1, and an oil outlet 21 is formed at the bottom of the oil cup 1. In this embodiment, the oil The outside of cup 1 is provided with a heating belt for oil refining.

[0040] The adjustment control mechanism includes a speed limiting lever 2, a guide control lever 6, an adjustment mechanism and a sliding sealing mechanism.

[0041] The speed limiting rod 2 is arranged in the vacuum chamber 22 , and...

Embodiment 2

[0049] The difference between the adjustment control mechanism of this embodiment and the first embodiment is that the adjustment mechanism in this embodiment is not a lever mechanism, but a figure 1 The guide control rod 6 and the adjustment rod 14 are directly fixedly connected through the connecting rod, as long as the guide control rod 6 can be linked with the adjustment rod 14, and the adjustment action of the adjustment rod 14 can be transferred to the guide control rod 6 is enough. When adjusting the oil filling speed, operate the control end of the adjustment rod 14 to adjust the relative distance between the speed limiting member 20 and the oil outlet 21 proportionally (including equal proportions, reduction or enlargement as required) through the lever mechanism in the chamber, Finally, the cross-sectional area of the oil outlet 21 suitable for the passage of oil is changed to realize the adjustment of the oil filling speed. Other structures of the adjustment cont...

Embodiment 3

[0052] The difference between the adjustment and control mechanism of this embodiment and the first embodiment is that, for another example figure 1 As shown, in this embodiment, the guiding control rod 6 and the speed limiting rod 2 are directly fixedly connected by a connecting rod, as long as the guiding control rod 6 and the speed limiting rod 2 can be linked, the adjustment action can be transferred to the Speed limit lever 2 is enough. When adjusting the oil filling speed, operate the control end of the adjusting lever 14 to adjust the relative distance between the speed limiting member 20 and the oil outlet 21 proportionally (including equal proportion, reduction or enlargement as required) through the external lever mechanism, Finally, the cross-sectional area of the oil outlet 21 suitable for the passage of oil is changed to realize the adjustment of the oil filling speed. Other structures of the adjustment control mechanism in this embodiment are the same as tho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com