Semi-closed forging device for universal joint and forging method thereof

A semi-closed, cross-shaft technology, used in forging/pressing/hammer devices, manufacturing tools, metal processing equipment, etc., can solve the problems of many cross-shaft flashes and low material utilization, reducing production costs and improving economy. The effect of improving efficiency and material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

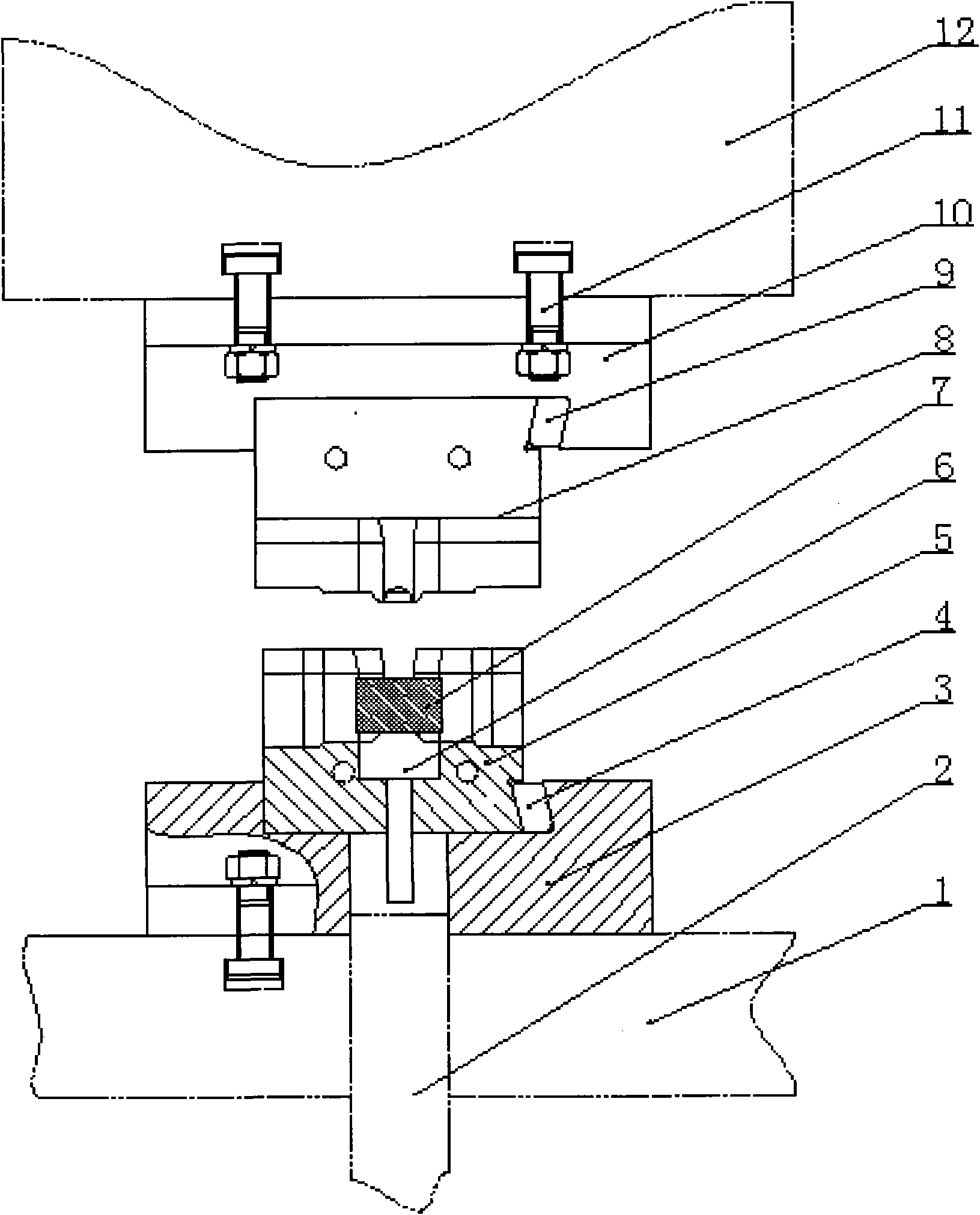

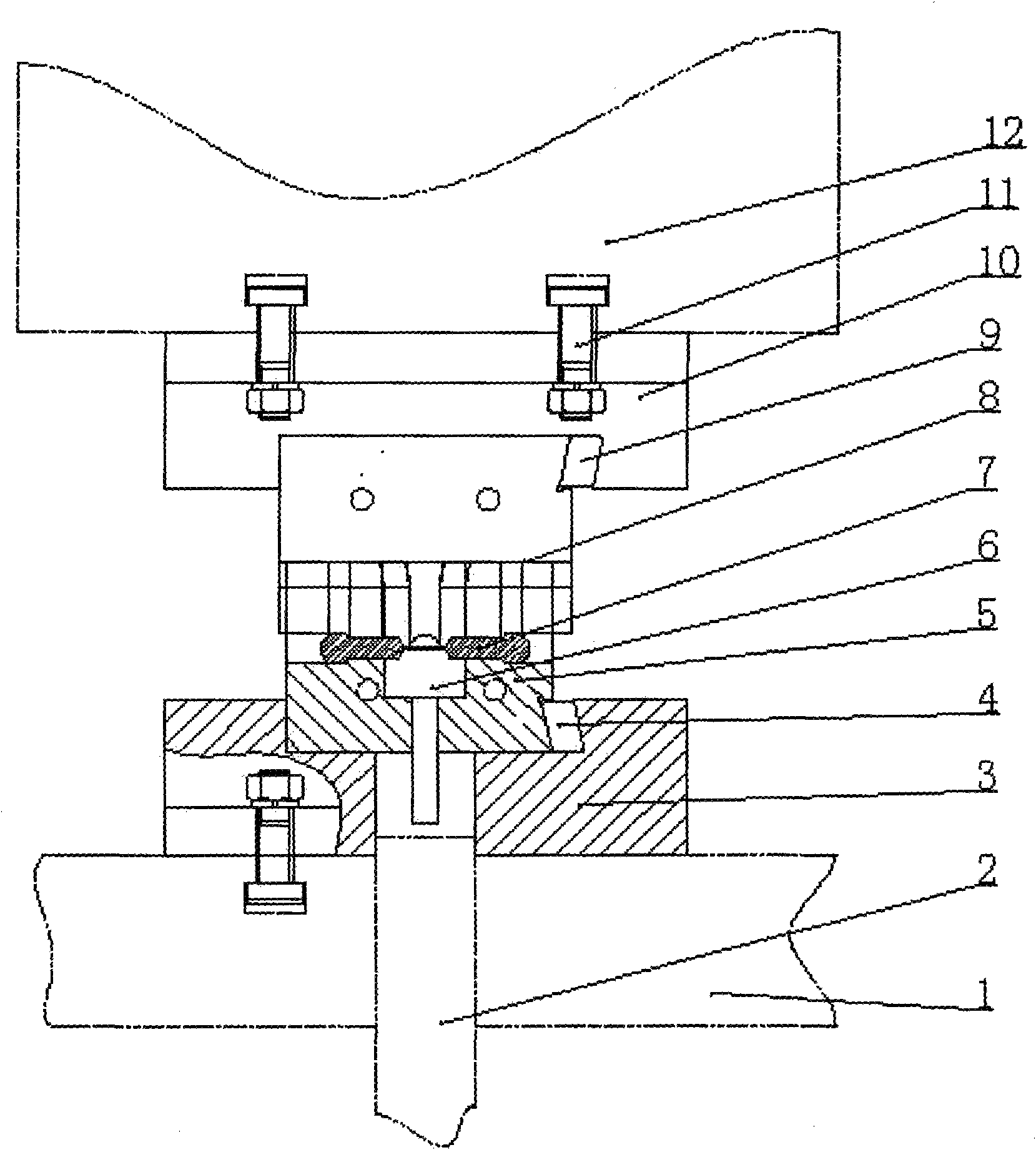

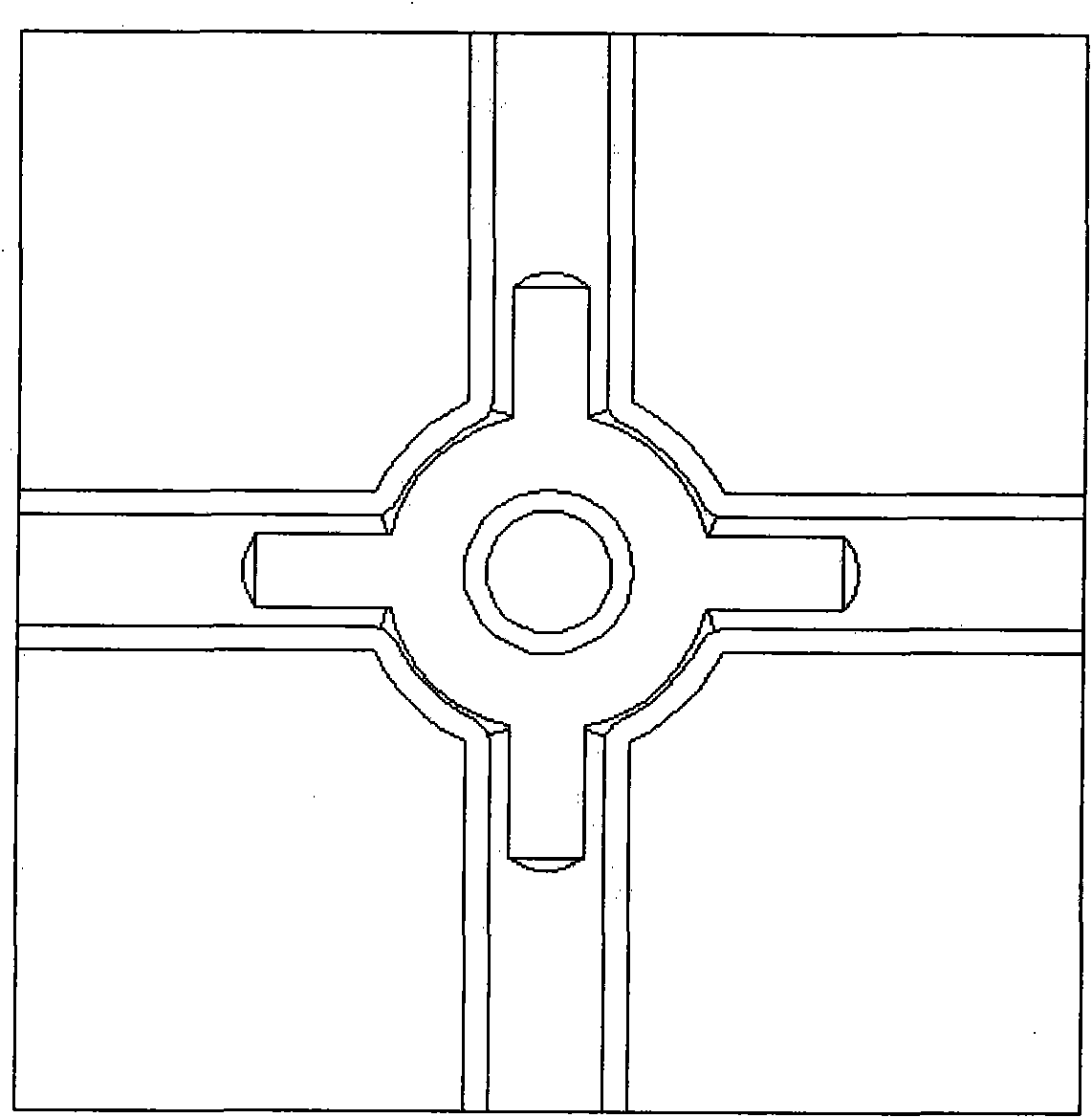

[0013] Such as Figure 1-4 As shown, the cross-axis semi-closed forging processing device includes a workbench 1, an equipment ejector mechanism 2, a lower mold base 3, a lower forging iron 4, a lower mold 5, an ejector rod 6, an upper mold 8, an upper forging iron 9, and an upper forging iron 9. Die base 10, hammer head 12; there is a T-shaped groove on the workbench 1, the lower mold base 3 is placed on the workbench, and the connecting groove is aligned with the T-shaped groove, and the lower mold base 3 is fixed on the workbench 1 by screws . The lower mold 5 is fixed on the lower mold base 3 with the lower fore iron 4; the upper mold 8 is fixed on the upper mold base 10 with the upper fore iron 9, and the upper mold base 10 is fixed on the hammer head 12 through the bolt 11; the upper mold base 8 is installed During this process, it should be ensured that the convex part of the upper mold 8 is aligned with the concave cavity of the lower mold 5 to ensure that the gap aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com