Production line of plastic garbage recycling and granulating complete equipment

A complete set of equipment and plastic waste technology, applied in the direction of coating, etc., can solve the problems of waste of resources, environmental pollution, low cleanliness, etc., and achieve the effect of solving the problem of recycling and avoiding white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples.

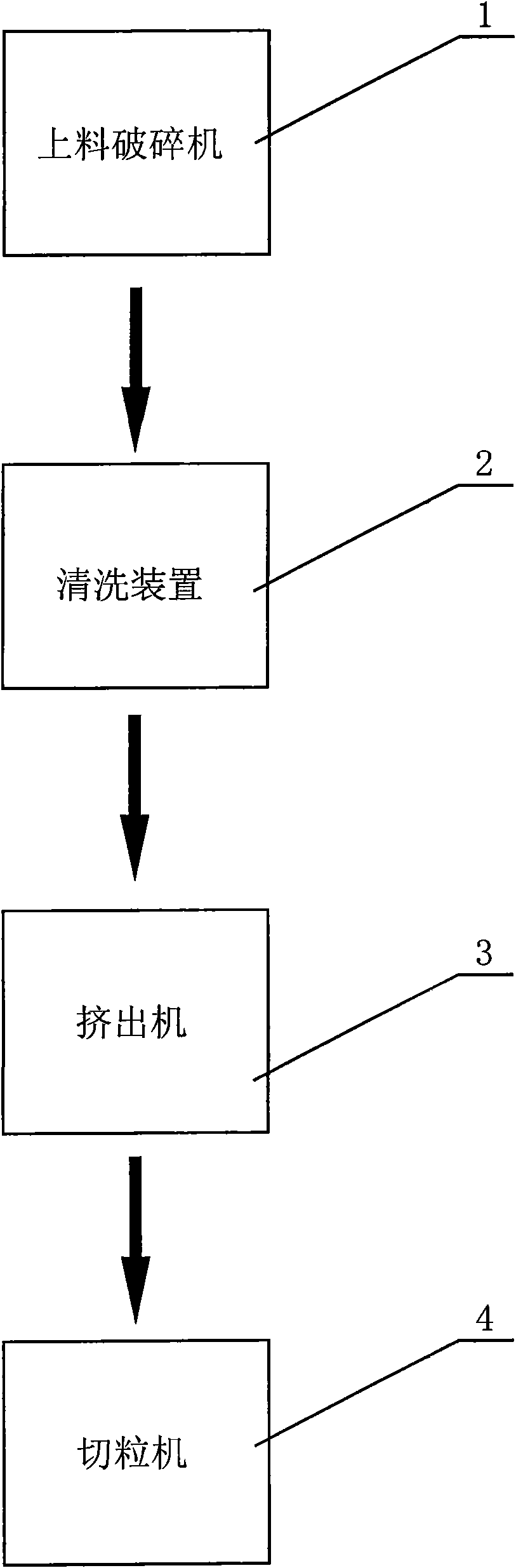

[0019] Such as figure 1 As shown, this embodiment includes a feeding crusher 1 , a cleaning device 2 , an extruder 3 and a pelletizer 4 connected sequentially from front to back.

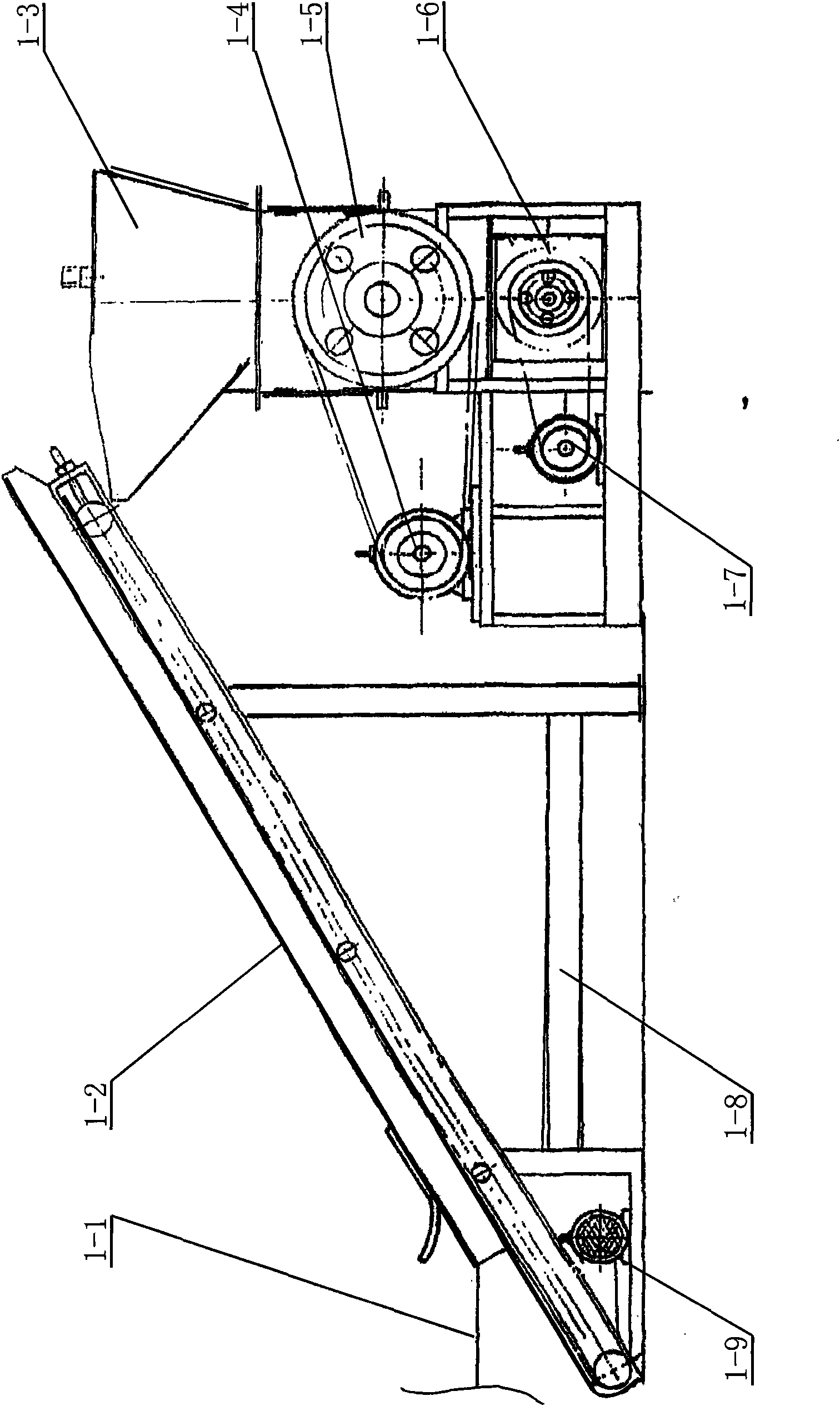

[0020] Such as figure 2 As shown, the feeding crusher 1 is composed of a conveyor frame 1-8, a conveyor belt 1-2 installed on the conveyor frame 1-8 and a crusher 1-5 behind the conveyor belt. 1-8 is also equipped with a conveying motor 1-9 for driving the operation of the conveyer belt 1-2, and the upper end of the crusher 1-5 is equipped with a crushing hopper 1-3, and the rear of the conveyer belt 1-2 is The end is lapped on the upper port of the crushing hopper 1-3, and the discharge end of the crusher 1-5 is also connected with a pusher auger 1-6. Also be equipped with plastic waste hopper 1-1 on conveying frame 1-8.

[0021] The crusher 1-5 is installed on the crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com