Preparation method of water-based polyacrylate modified polyurethane dispersion (PUD)

A polyurethane dispersion, polyacrylate technology, applied in the direction of polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of short application period and inconvenient coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Preparation of Waterborne PA Modified PU Dispersion

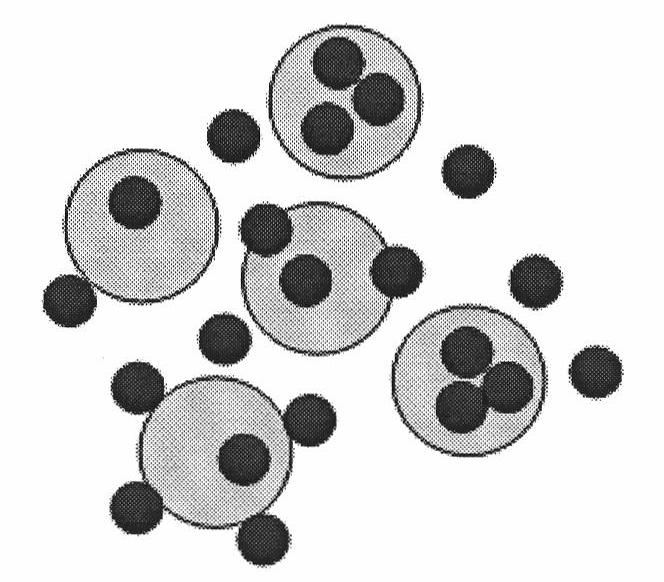

[0048] In order to prepare aqueous PA / PU hybrid dispersions, some important factors that must be considered include: (i) the high viscosity of the PU prepolymer; (ii) the difficulty of free radical polymerization of the acrylate monomer in the presence of PU (iii) the mutual promotion of PA and PU properties; and (iv) the convenience of operation and the high yield of the production process.

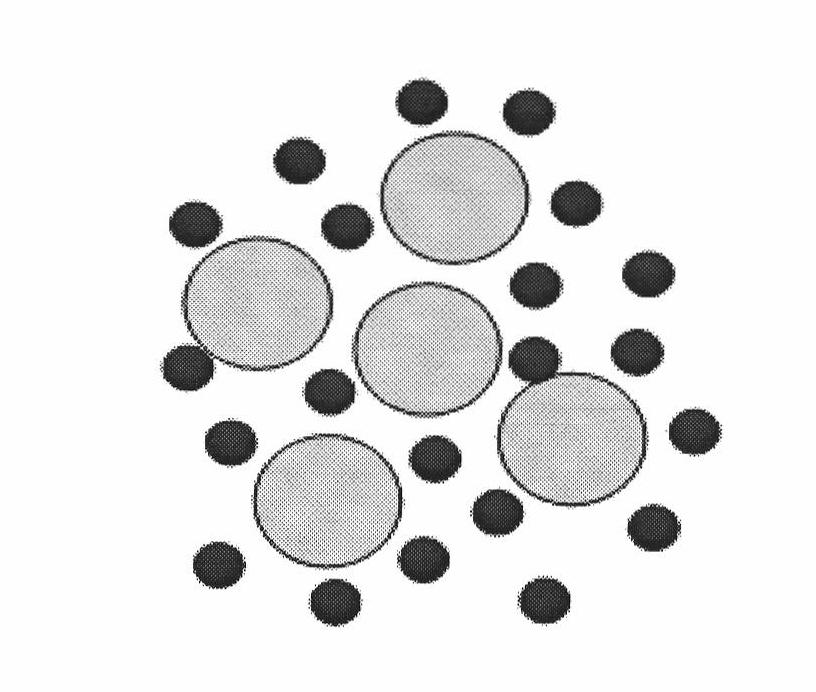

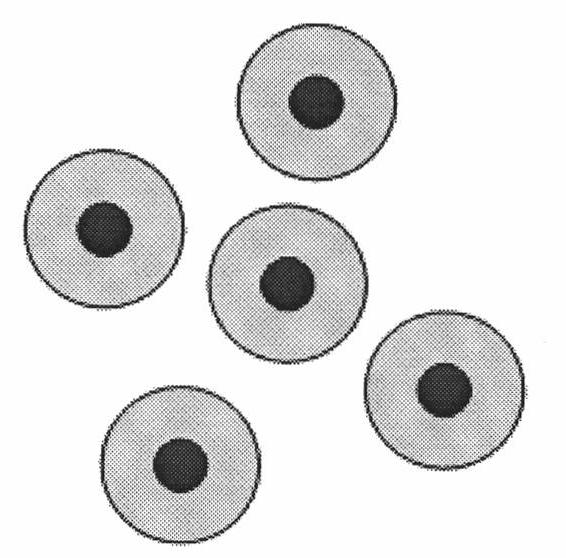

[0049] To improve workability, it is best to avoid the polymerization of acrylates in the presence of PU. As we all know, acrylate emulsions have good design and controllability, including the particle size and particle size distribution of polymer emulsions, particle structure and morphology, etc. The engineering-friendly structure and performance of acrylate polymer emulsions are the reasons why many researchers and technicians to engage in their research. Through the emulsion polymerization of acrylate, it is easy to obt...

example

[0094] Commonly used araliphatic polyisocyanates include but are not limited to the following examples: m-tetramethylene xylylene diisocyanate, p-tetramethylene xylylene diisocyanate, 1,4-xylylene diisocyanate , 1,3-xylylene diisocyanate and the like. The most commonly used araliphatic polyisocyanate is tetramethylene xylylene diisocyanate.

[0095] Suitable aromatic polyisocyanates include, but are not limited to, the following examples: 4,4'-dibenzylidene diisocyanate, toluene diisocyanate and its isomers, naphthalene diisocyanate, and their oligomers and the like . The most commonly used aromatic polyisocyanate is toluene diisocyanate.

[0096] According to the present invention, hydroxycarboxylic acid is used as the water dispersion strengthening agent. In the preparation of PU prepolymer, the hydroxyl group will react with the isocyanate group and its carboxyl group will remain, so as to provide hydrophilicity for the PU molecular chain. Polyurethane is generally hydr...

Embodiment

[0120] The present invention can further illustrate technical details through the following examples, but it must be noted that the present invention is not limited to the scope involved in the following examples. In the following examples and detailed descriptions, all amounts measured in "parts" or percentages are parts by weight or ratios by weight, unless otherwise stated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com