Novel reinforced composite paper

A new type of paper and technology, applied in the field of new and improved paper structure, can solve the problems of poor strength and toughness, not moisture-proof and waterproof, and achieve the effects of high production efficiency, strong toughness and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

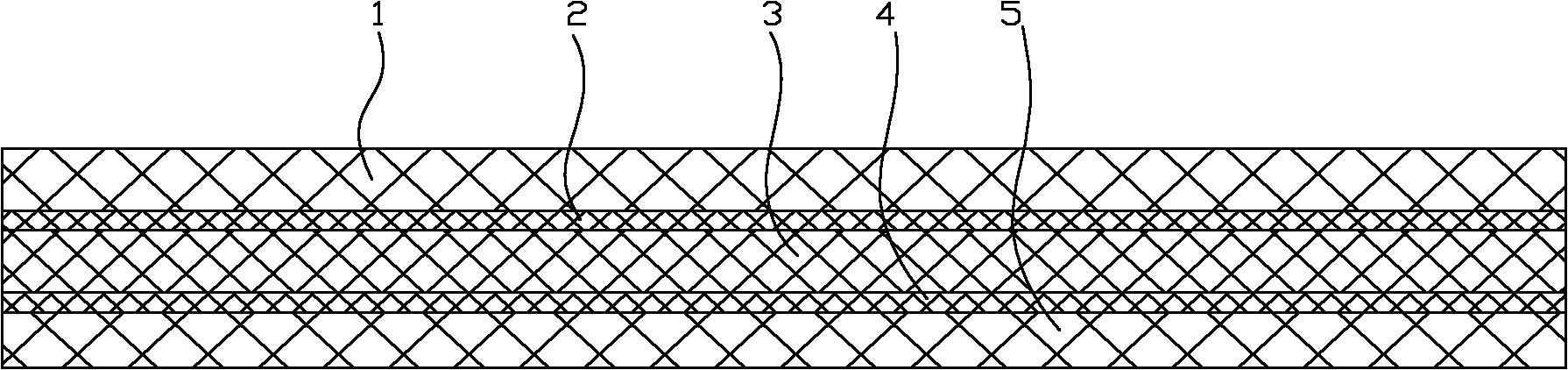

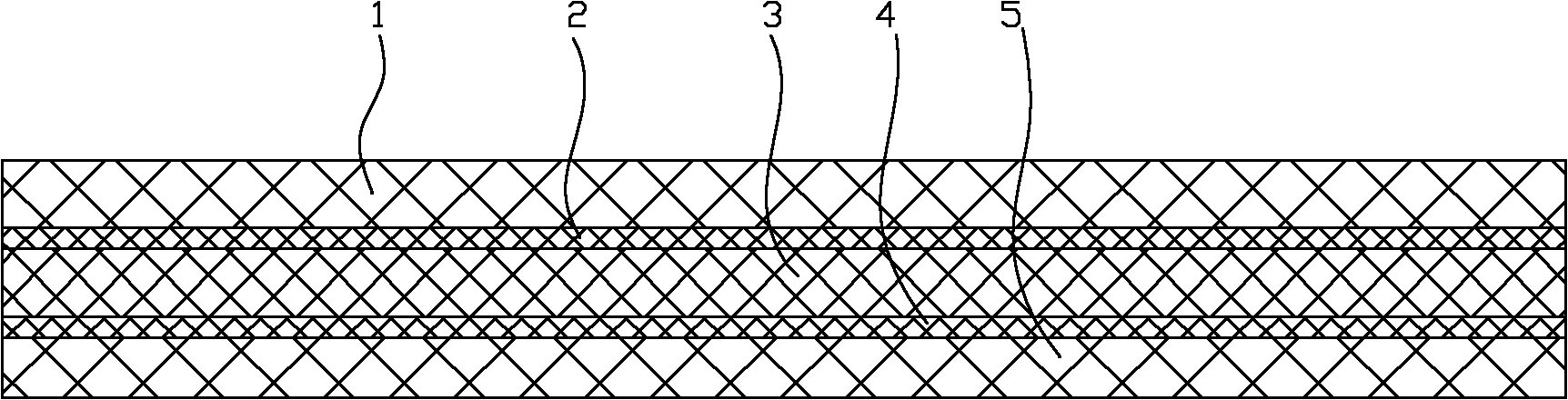

[0007] Structure of the present invention sees figure 1 , its layer structure is the upper paper layer 1, polypropylene and polyethylene fusion bonding layer 2, PET or OPP or PVC or plastic braided cloth reinforcement layer 3, polypropylene and polyethylene fusion bonding layer 4 and the lower paper layer 5.

[0008] The upper paper layer 1 is bonded with PET or OPP or PVC or plastic woven cloth reinforcing layer 3, PET or OPP or PVC or plastic woven cloth reinforcing layer 3 is bonded with lower paper layer 1 through adhesive layers 2 and 4, and the adhesive layer 2 and 4 are composed of polypropylene and polyethylene melt adhesives as bonding materials after being melted at high temperature.

[0009] When the reinforcing layer is PET, the bonding of polypropylene and polyethylene melt adhesive is best at the melting temperature of 380°C-400°C.

[0010] When the reinforcing layer is OPP, the bonding of polypropylene and polyethylene melt adhesive is best when the melting te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com