Double-channel turbine bypass bleeding device

A bleed device and double-channel technology, which is applied to gas turbine devices, machines/engines, internal combustion piston engines, etc., can solve the problem of increased mechanical wear of actuators and transmission mechanisms, instability of turbine inlet pressure and waste gas bypass, and impact on turbines. Supercharger engine working stability and other issues to achieve the effect of improving working stability, avoiding constant changes in valve opening, and avoiding abnormal wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

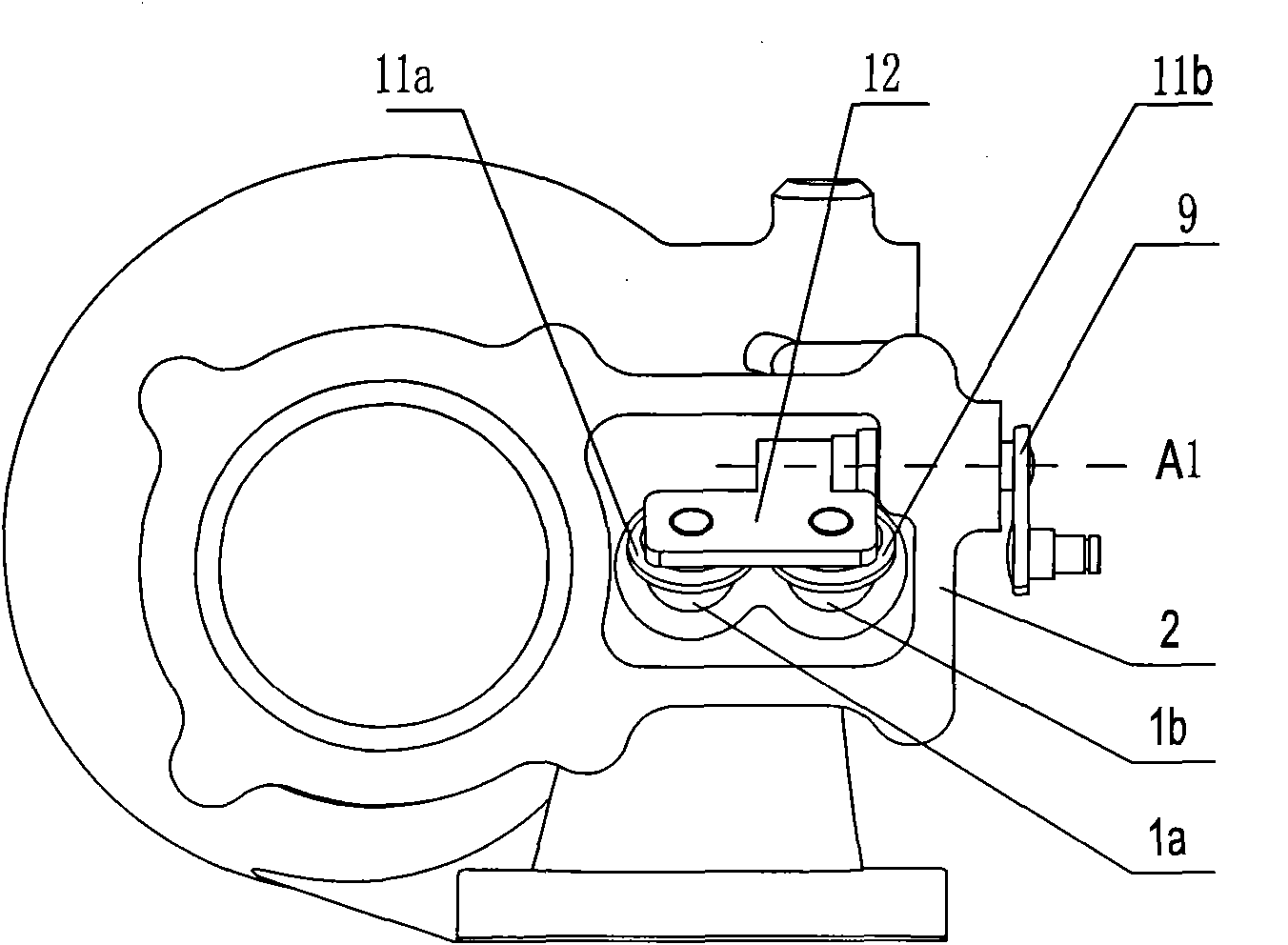

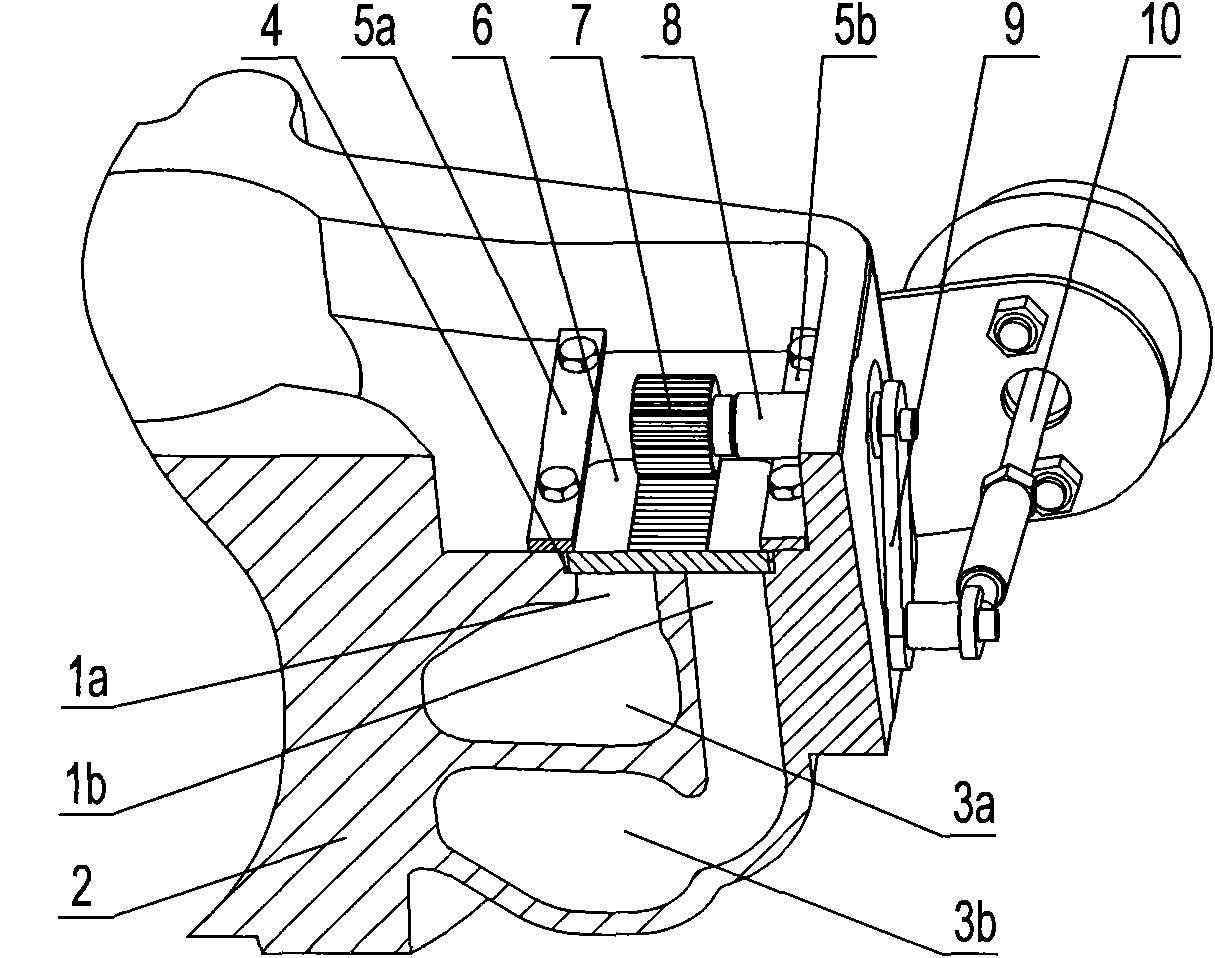

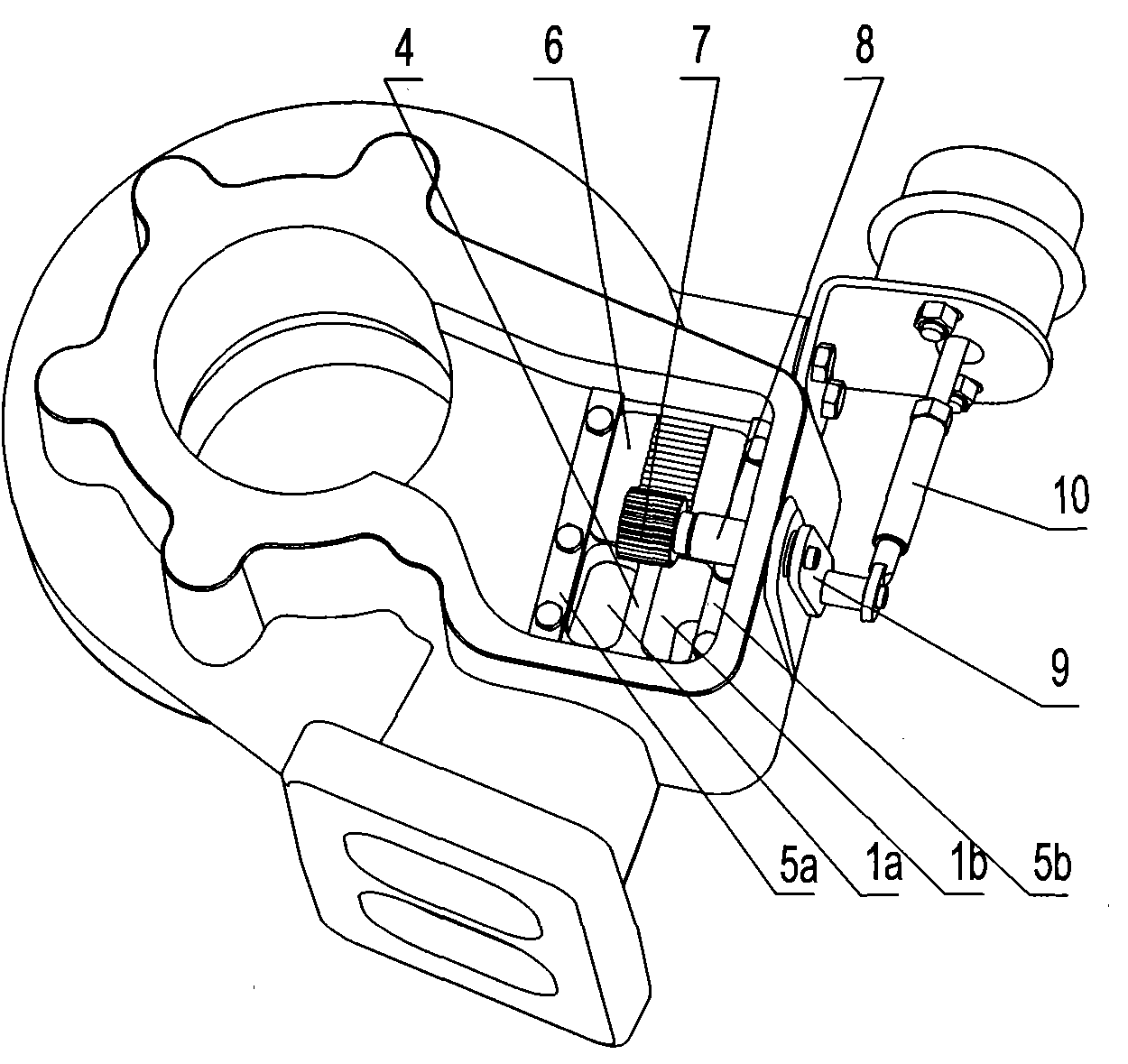

[0032] Examples, as attached figure 2 As shown, a double-channel turbine bypass air-bleed device for a double-channel turbocharger whose valve opening and bypass air-bleed volume can be precisely controlled includes a turbine volute 2, and the turbine volute 2 is provided with The first air intake channel 3a of the volute and the second air intake channel 3b of the volute, the first air intake channel 3a of the volute is communicated with the first air release channel 1a, and the second air intake channel 3b of the volute is communicated with the second air discharge channel 3b. Air channel 1b, the outlet of the first air release channel 1a and the second air release channel 1b is provided with a concave valve seat 4, and a common valve cover 6 is provided on the concave valve seat 4, and the valve cover 6 It is slidingly connected with the concave valve seat 4, and the valve cover 6 is in transmission connection with the power drive device.

[0033] The concave valve seat 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com