Valveless piezoelectric pump of elliptical combined pipe

A technology of valveless piezoelectric pumps and combined tubes, which is applied in the direction of pumps, pump components, variable-capacity pump components, etc., and can solve the problems of large-scale confluence tubes and shunt tubes, unfavorable micro-integration, and small positive and negative flow resistance ratios. and other problems, to achieve the effect of easy flow control, remarkable energy saving effect, and small flow eddy current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

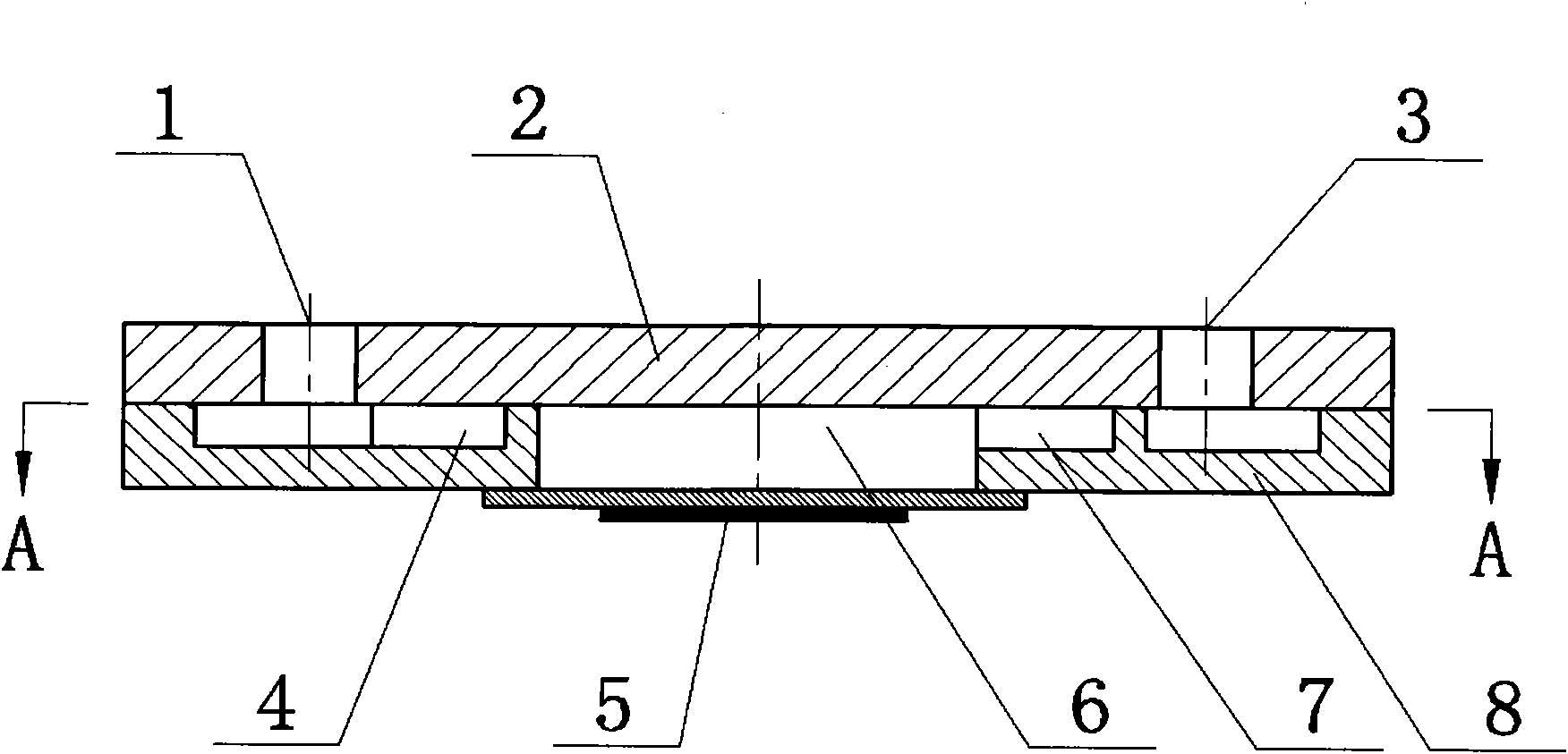

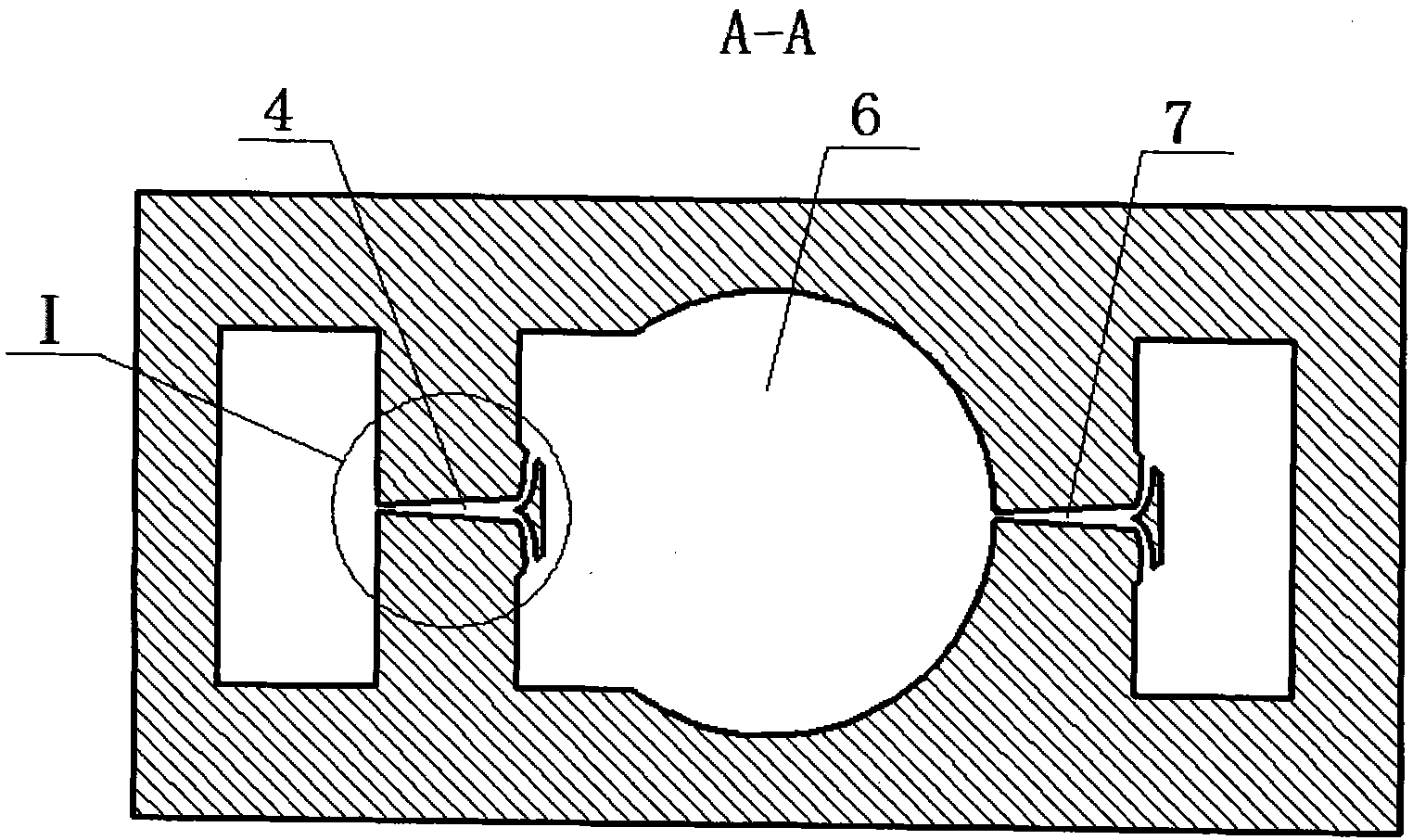

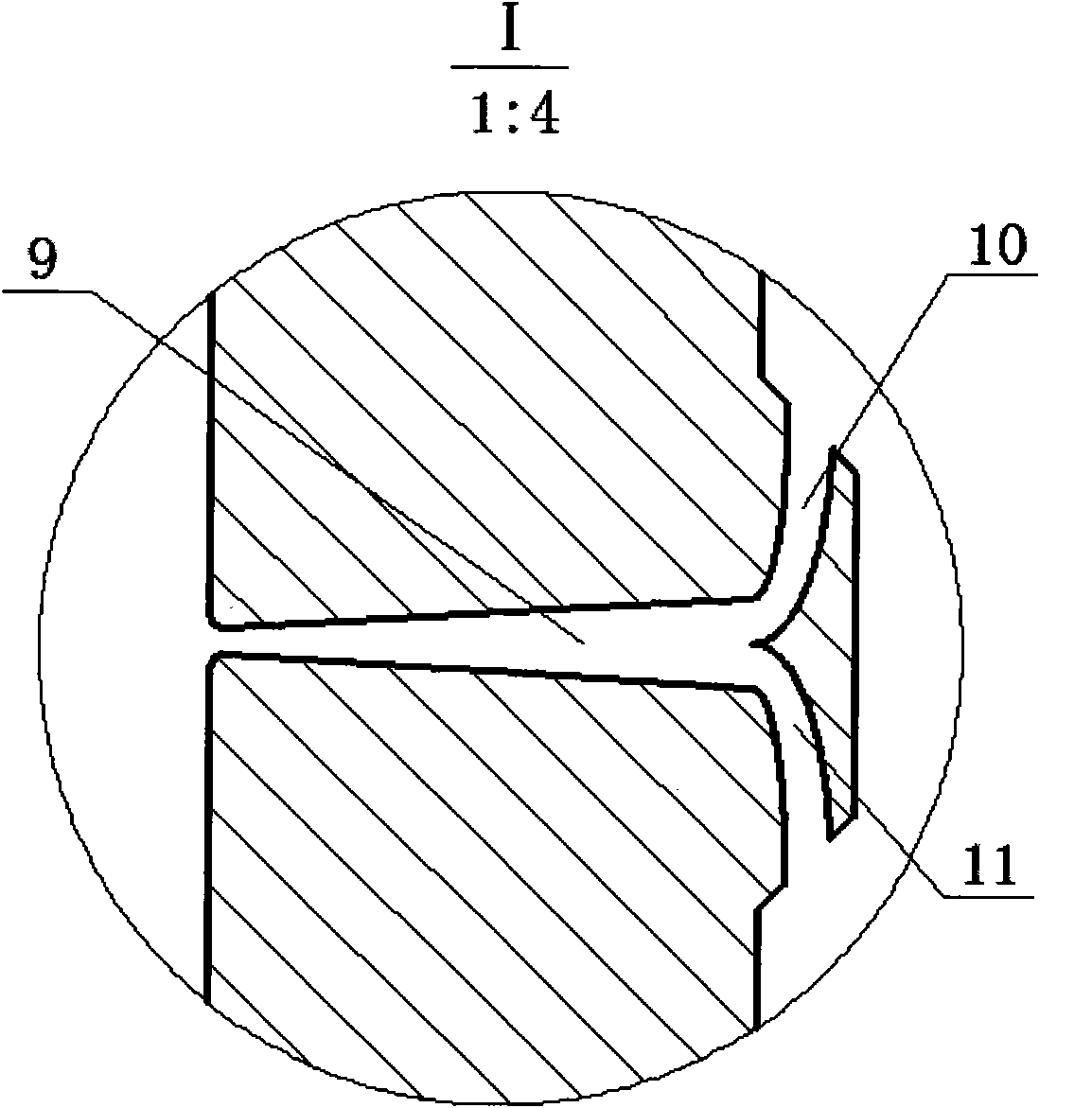

[0013] Such as Figure 1-3 , the present invention includes a pump body 8, a pump cover 2 and a piezoelectric vibrator 5, the pump body 8 and the pump cover 2 are electrostatically bonded together, and the piezoelectric vibrator 5 is fixed at the center of the lower part of the pump body 8 by an adhesive. A pump inlet 1 and a pump outlet 3 are processed on the pump cover 2, and the pump inlet 1 and the pump outlet 3 are externally connected with an inlet pipe and an outlet pipe respectively. Two inlet flow tubes 4, outlet flow tubes 7 and pump cavity 6 of the same structure are processed on the pump body 8 by using MEMS processing technology, wherein the pump cavity 6 is located between the inlet flow tube 4 and the outlet flow tube 7, and the inlet flow tube The pipe 4 and the outlet flow pipe 7 communicate with the pump chamber 6 respectively, and the three communicate with each other. The two inlet flow tubes 4 and outlet flow tubes 7 of the same structure are arranged coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com