Automatic magnetic roller paint spraying equipment

An automatic painting and magnetic roller technology, applied in the direction of spraying devices, etc., can solve the problems of complex operation, low efficiency, and unguaranteed spraying quality, and achieve the effect of simple equipment structure, convenient operation, and reliable spraying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

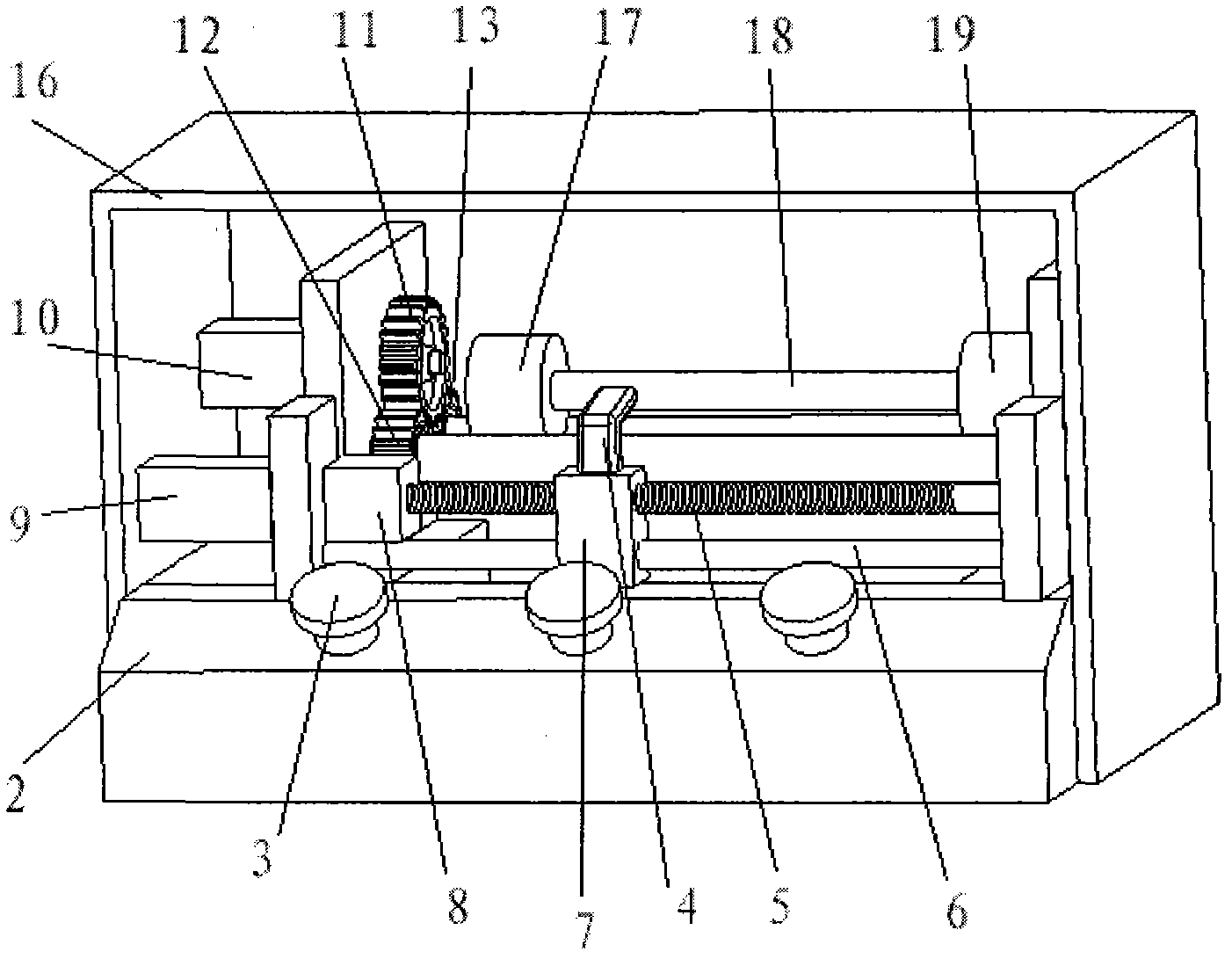

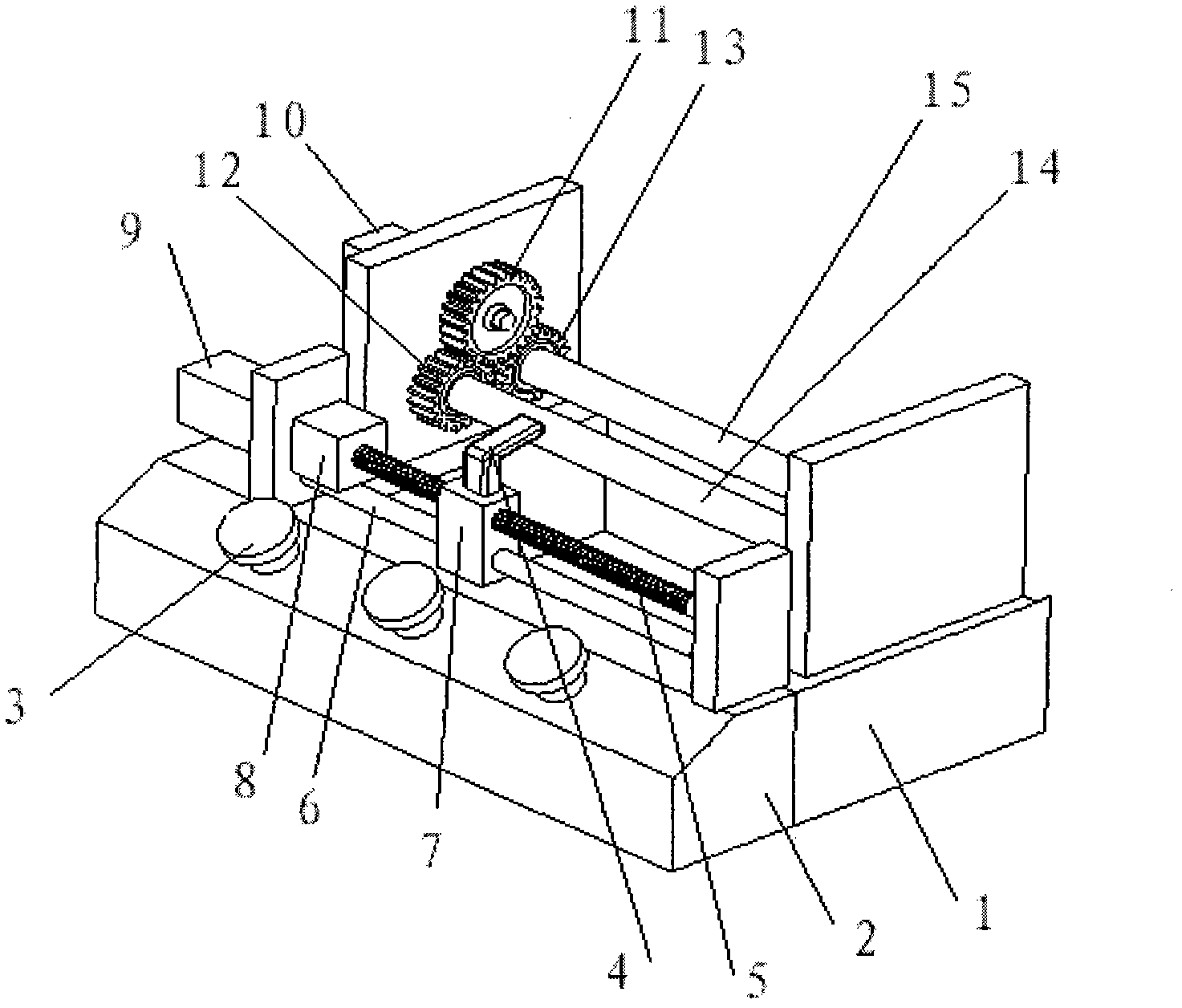

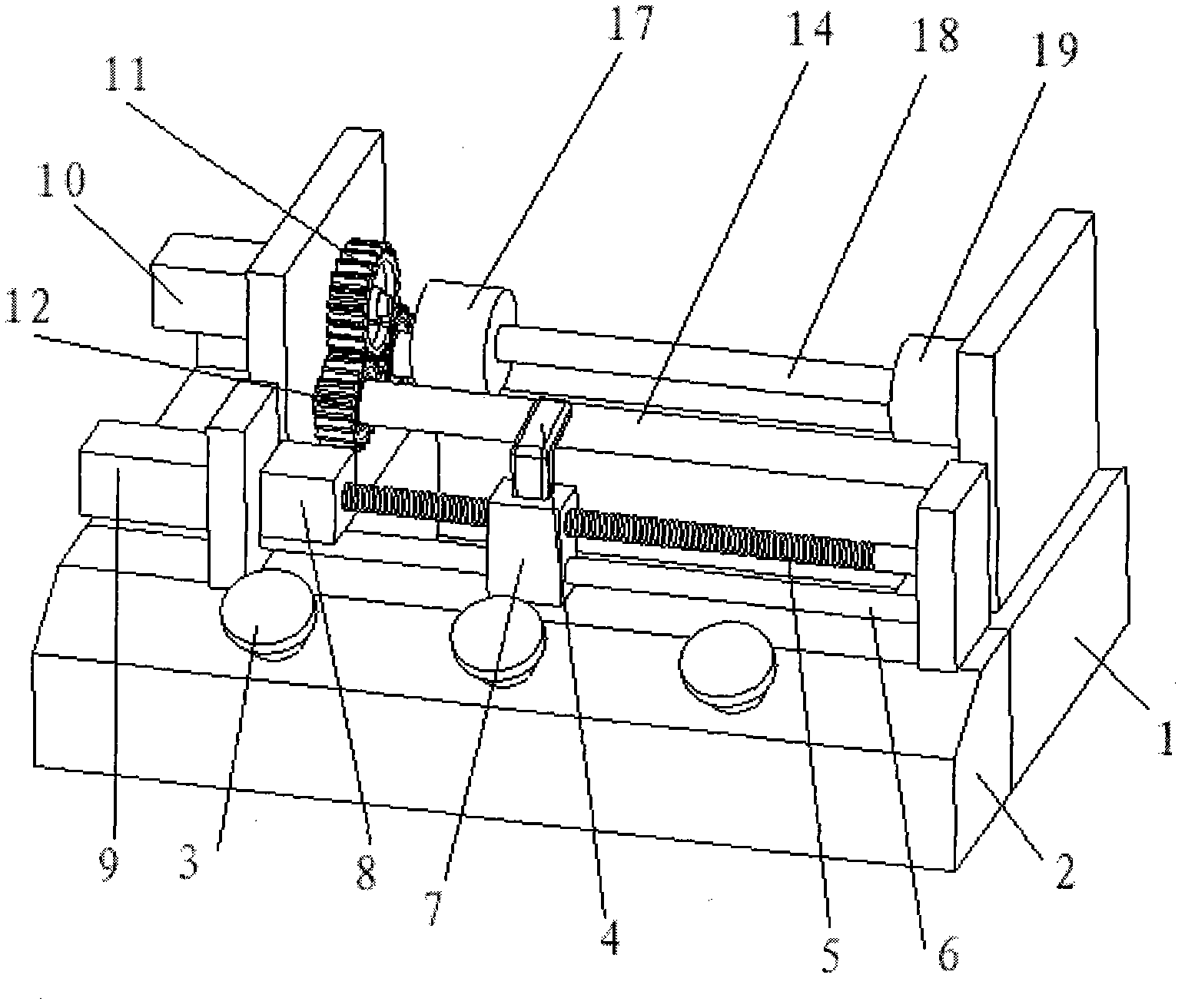

[0014] see figure 1 , 2,3 An automatic inflation device for an inflatable bag, the device consists of a base (1), a water curtain spray cabinet (16), a magnetic roller power transmission system, a spray gun moving device and an electrical control cabinet (2).

[0015] The magnetic roller power transmission system and the spray gun moving device are installed in parallel on the base (1), and are arranged inside the water curtain spraying cabinet (16). The electrical control cabinet (2) is placed in parallel with the spray gun moving device in the water curtain spraying cabinet (16 ) outside; the motor (10) in the magnetic roller power transmission system is installed on the support of the base (1), and the large gear (11) is installed on the motor (10) main shaft, and on the support of the motor (10), the motor ( 10) On both sides of the main shaft, install shaft I (14) and shaft II (15) parallel to the axis of the motor shaft. Two pinion gears I (12) are arranged on shaft I (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com