Adjustable heat collecting device for rotary kiln body

A collection device and rotary kiln technology, which is applied in rotary drum furnaces, waste heat treatment, lighting and heating equipment, etc., can solve the problems of heat energy not being well utilized, useless heat recovery and efficiency decline, etc., so as to achieve recycling and utilization. The effect of reducing the energy consumption of equipment, short payback period and reducing equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

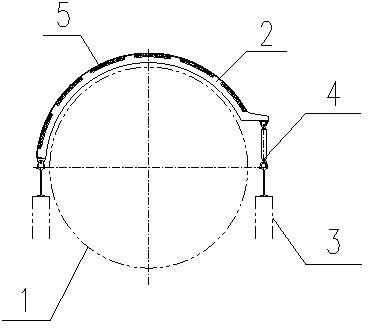

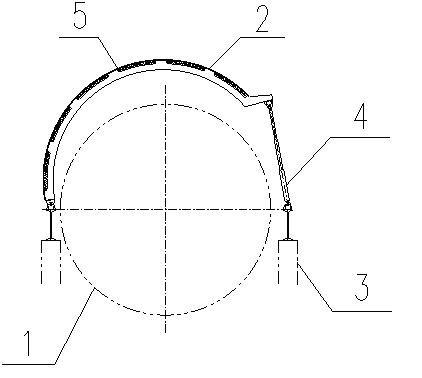

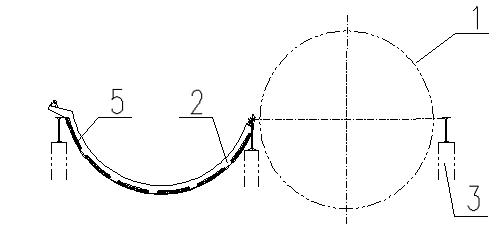

[0014] Such as figure 1 and 2 As shown, the heat collection unit is composed of a heat collection cover 2 , a bracket 3 and a position adjustment system 4 . Two brackets 3 are installed on both sides of the carcass of the rotary kiln 1, one of the brackets 3 is directly connected to the heat collecting cover 2, and the other bracket 3 supports the heat collecting cover 2 through the position adjustment system 4, and the heat collecting cover 2 is controlled by the heating surface 5 , thermal insulation material and fixed material, the change of the heat collected by the heat collecting unit can be realized by adjusting the whole device.

[0015] Among them, the position adjustment system 4 is composed of a support mechanism and an actuator, and the actuator is a telescopic device. The telescopic actuator can be a wire sleeve, that is, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com