Metal optical grayscale mask and manufacturing method thereof

一种灰度掩模、金属的技术,应用在金属-金属氧化物体系光学灰度掩模及其制作领域,能够解决提高HEBS玻璃灰度掩模价格、很难大规模应用、生产成本高等问题,达到节省能源、制作过程快速、稳定性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

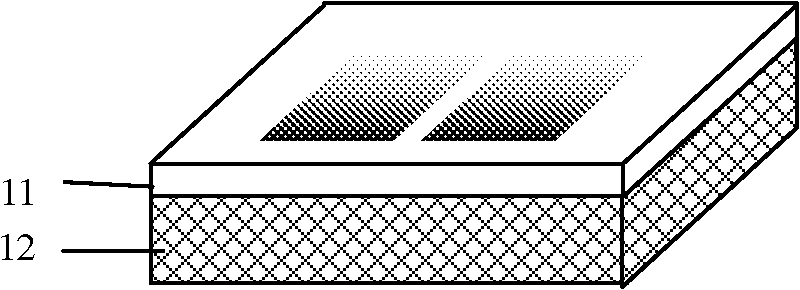

[0056] The metal optical gray scale mask of the present embodiment is made of transparent substrate 12, and on transparent substrate 12 deposits one deck Sn metal thin film 11, and adopts laser direct writing method to make the gray scale of Fig. 1 composition at Sn metal thin film 11 mask; wherein, the transparent substrate 12 is quartz glass. The thickness of Sn metal thin film 11 is 5 or 20 nanometers; The laser power that adopts during laser direct writing is 1-5 milliwatts, and laser pulse width is 230 nanoseconds, and the sample moving step that adopts is 150 nanometers; In this Sn metal thin film 11, laser direct writing or direct writing through the substrate is performed on the surface of the metal thin film to make a metal optical grayscale mask as shown in FIG. 1 .

[0057] refer to Figure 1a ,right Figure 1a The preparation method of the metal optical grayscale mask is described:

[0058] First of all, choose ordinary glass, quartz sheet, crown glass or PC plast...

Embodiment 2

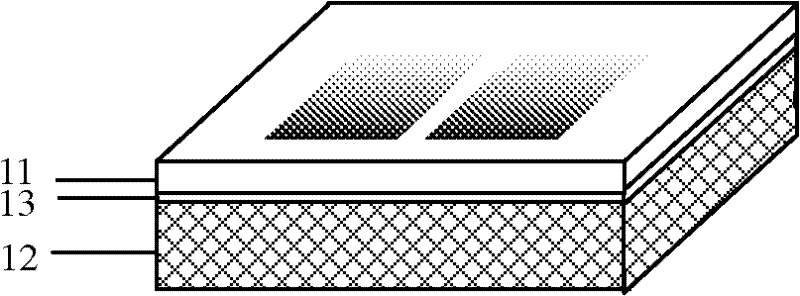

[0071] refer to Figure 2a and Figure 2b , deposit an In metal film 11 on a clean quartz substrate 12 with a DC magnetron sputtering method, for example, with a thickness of 50 nanometers. Then use the above-mentioned laser direct writing device to make a mask, and the laser power range corresponding to the above-mentioned thickness is 0.3-4 milliwatts, 1-10 milliwatts, and 1-70 milliwatts. The pulse width of the laser used is 100 nanoseconds, 1 micron, and 1 millisecond, and the step length of the sample moving stage is 50 nanometers, 200 nanometers, and 300 nanometers. Other specific production methods are the same as in Example 1.

Embodiment 3

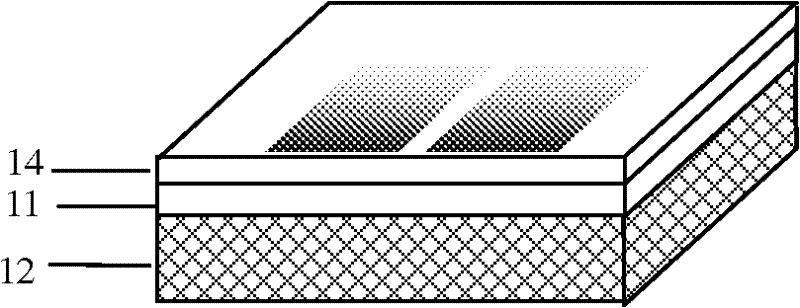

[0073] refer to Figure 2b , on the quartz glass substrate 12, deposit a 2-nanometer thick Cr strengthening film by radio frequency magnetron sputtering, and then deposit a layer of InSn (atomic ratio 1: 1) metal thin film 11, for example, the thickness is 5, 20, 100 Nanometer; in the laser direct writing process, the corresponding laser power for making grayscale masks is 1-5 milliwatts, 1-4 milliwatts, and 1-20 milliwatts. Continuous laser writing is used, with a step size of 350 nanometers between lines. After the laser direct writing is finished, a layer of ZnS-SiO is deposited on the metal film 11 by radio frequency magnetron sputtering. 2 The protection layer 14, the thickness of the protection layer 14 is 100 or 200 nanometers. Other specific production methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com