Optical filter for display, method for manufacturing the same, and display and plasma display panel equipped with optical filter for display

A technology of optical filter and manufacturing method, applied in the direction of optics, optical components, nonlinear optics, etc., to achieve the effect of easy grounding and suppression of peeling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0197]

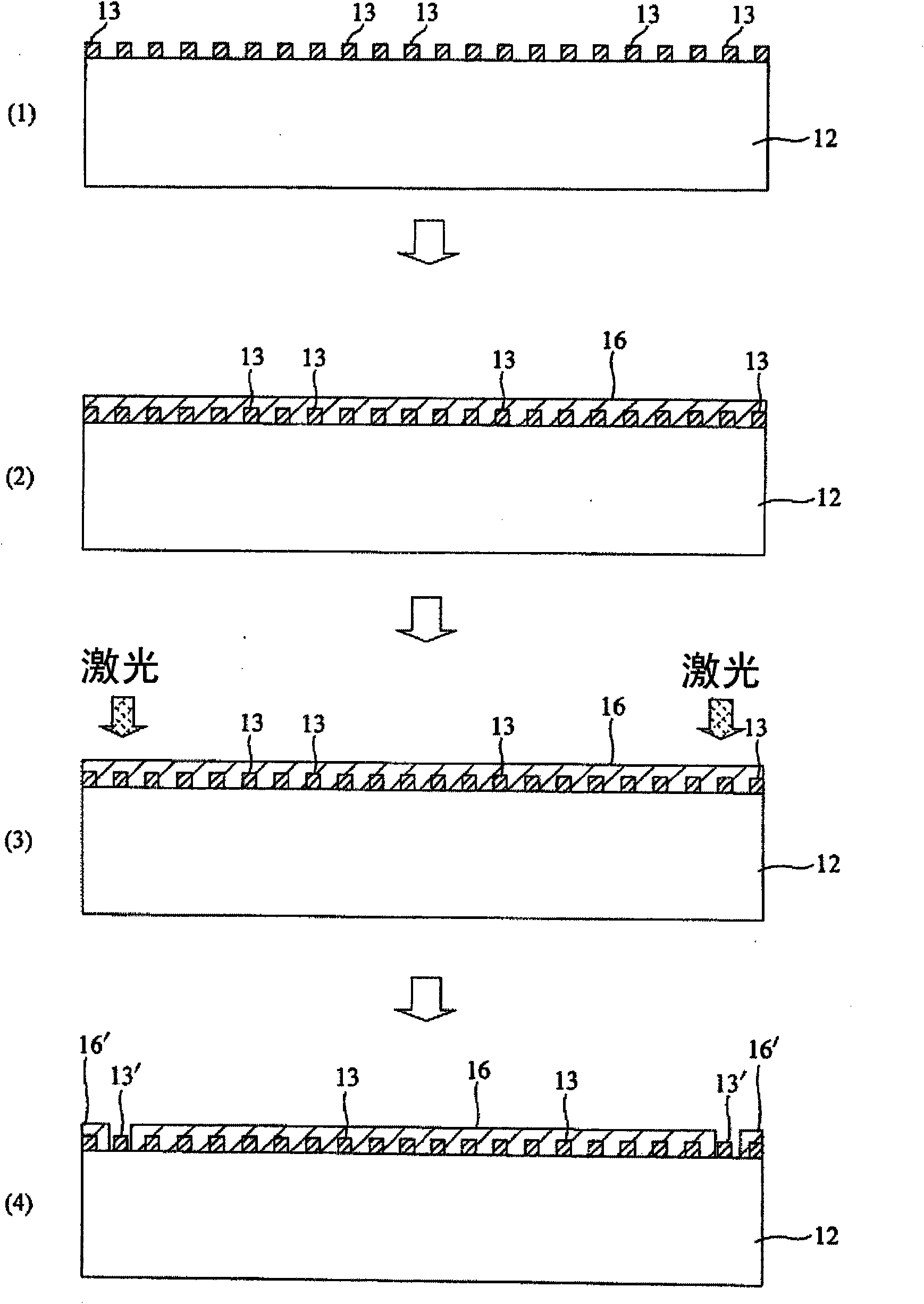

[0198] (1) Formation of mesh metal conductive layer

[0199] Polyethylene terephthalate film (width: 600mm, length 100m) with a 100μm-thick long polyethylene terephthalate film (width: 600mm, length 100m) having an easy-adhesive layer (polyester polyurethane; thickness 20nm) on the surface is printed with dots of polyester 20% aqueous solution of vinyl alcohol. The size of one dot is a square shape with a side length of 234 μm, the interval between dots is 20 μm, and the dots are arranged in a square lattice. The printing thickness was about 5 μm after drying.

[0200] Copper with an average film thickness of 4 μm was vacuum-deposited thereon. Then immerse it in water at normal temperature, wipe it with a sponge, dissolve and remove some of the dots, then wash it with water, and form a mesh conductive layer on the entire surface of the polyethylene film after drying (refer to figure 1 (1)).

[0201] The conductive layer on the surface of the film is a square gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com