Boarding vehicle

A boarding vehicle and frame technology, which is applied in the field of boarding vehicles, can solve the problems of limited use range, large floor space and low investment utilization rate, and achieves a wide application range, small floor space and high versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

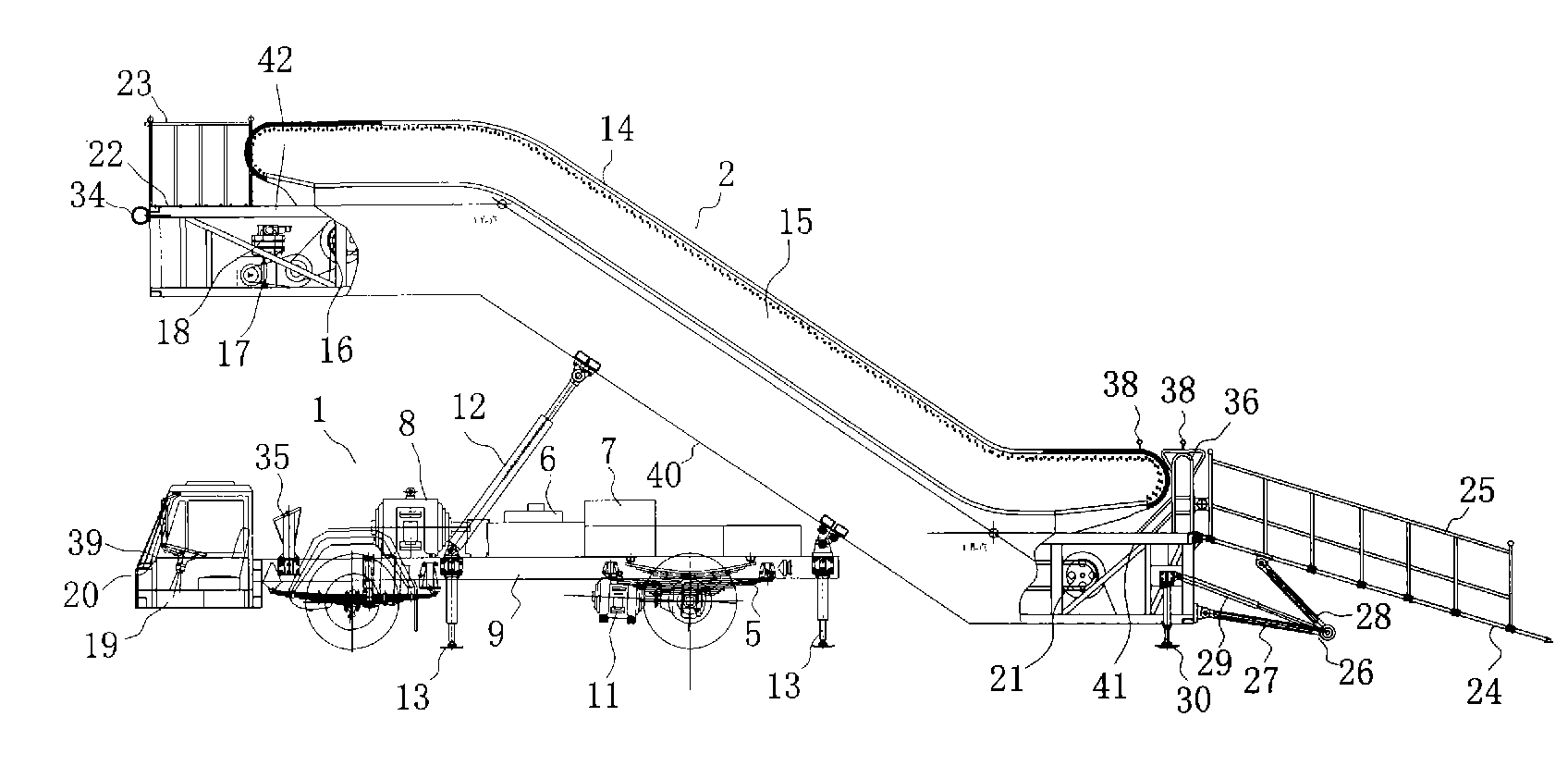

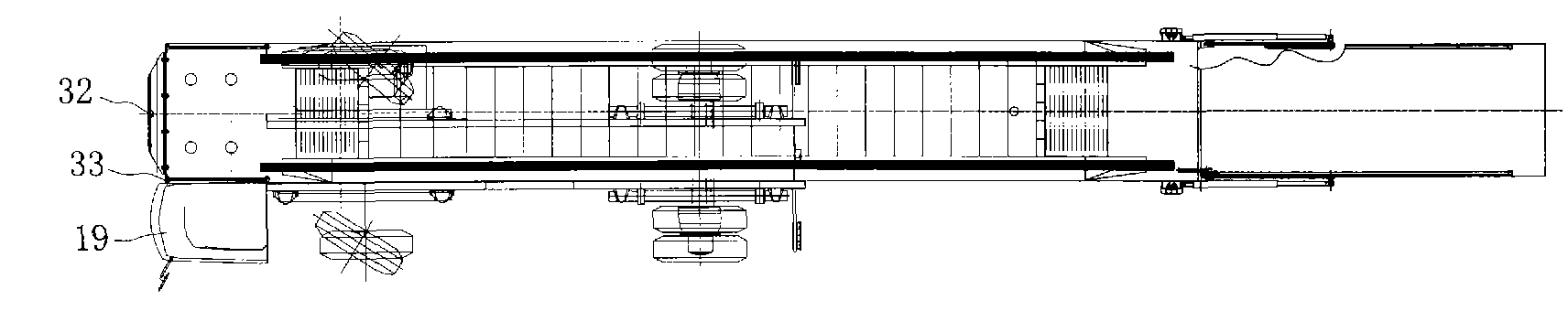

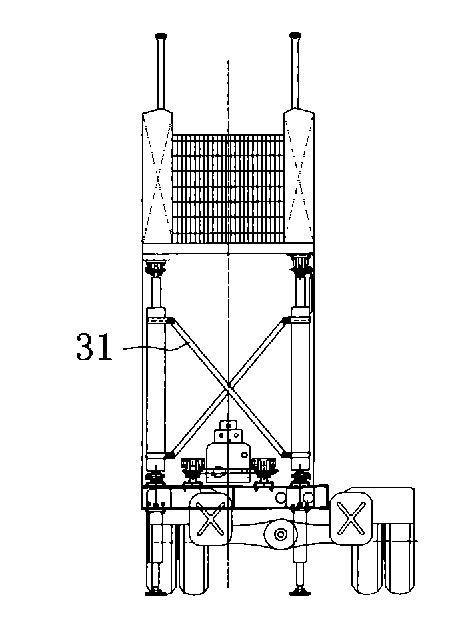

[0021] Such as figure 1 , figure 2 As shown, the boarding car of the present invention is made up of cab 19, electric vehicle chassis assembly 1, automatic boarding escalator assembly 2, electronically controlled hydraulic system and electronic program control system. The automatic boarding escalator assembly 2 is arranged on the upper part of the electric vehicle chassis assembly 1, and the electronic program control system controls the electronically controlled hydraulic system to drive the automatic boarding escalator assembly 2 up and down, and the escalator pedals move.

[0022] The electric vehicle chassis assembly 1 is equipped with a prime mover, which is a brushless permanent magnet synchronous DC motor BSK-1.5-120KW / 3000r / min from Dalian Hengtian Permanent Magnet Motor Co., Ltd. Connected into a group to form a 14.4v / 400A battery pack, a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com