Reactor for maglev train

A technology for maglev trains and reactors, which is applied in the directions of signal inductors without magnetic cores, electric vehicles, electric traction, etc., can solve the problems of weakening the electromagnetic radiation inside the car, the electromagnetic environment pollution of the car, and reducing the capacity of the train to carry passengers. , to achieve the effect of saving vehicle suspension energy consumption, improving train passenger capacity, and eliminating life-threatening hidden dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

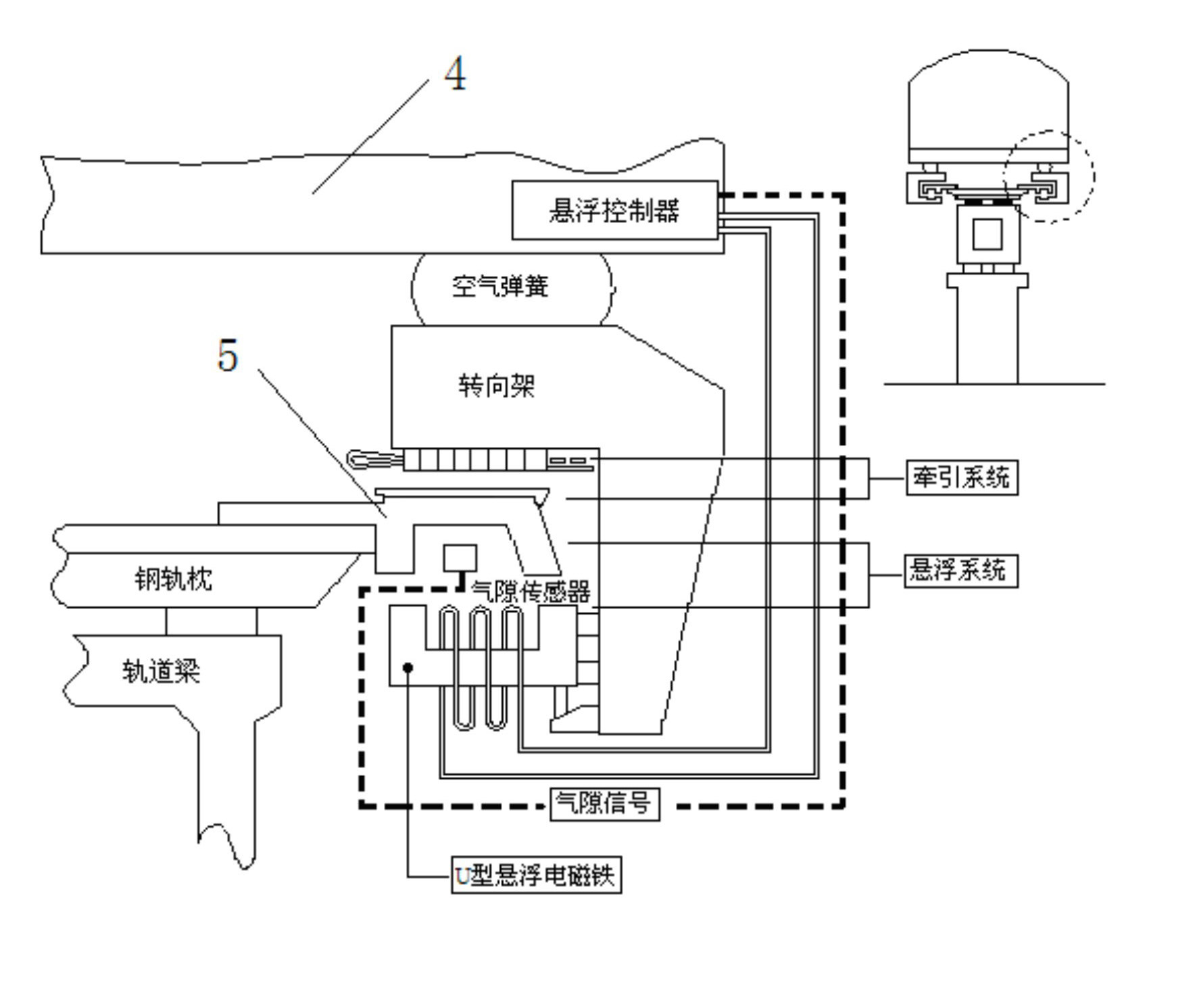

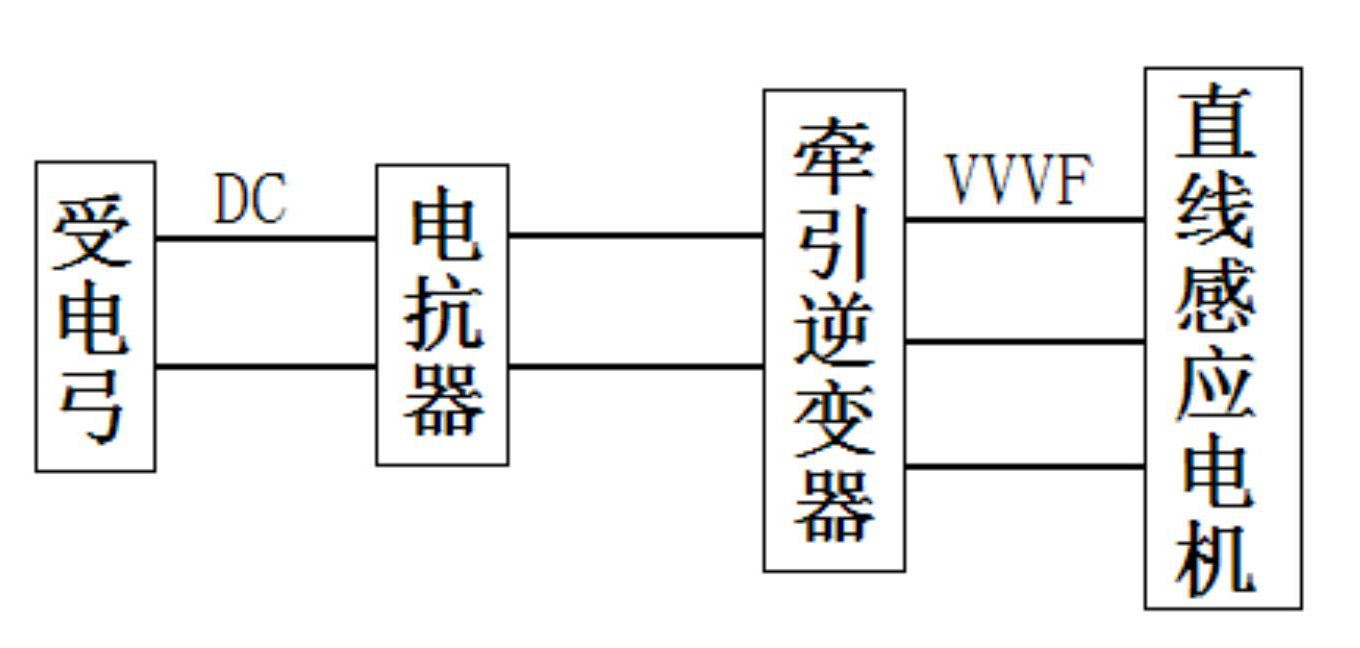

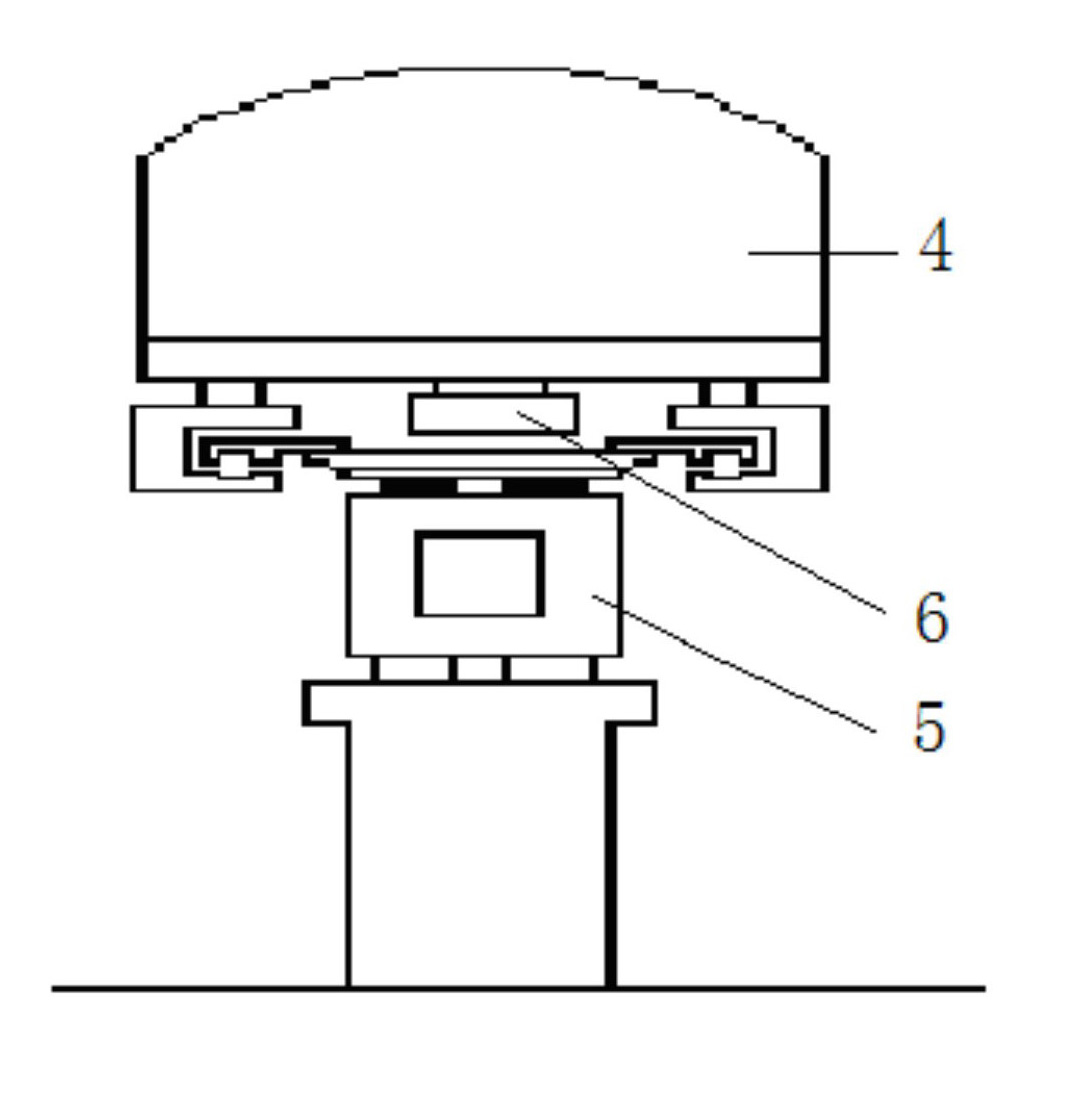

[0025] Maglev vehicles are also called maglev trains, maglev trains, maglev vehicles, maglev transportation, etc.; the reactors referred to below in the present invention are also called filter reactors, filter inductors, etc. Such as Figure 4 , Figure 5 and Figure 6 As shown, the reactor for maglev trains of the present invention includes an air-core coil 1, a shielding assembly is provided above the air-core coil 1 near the bottom plate of the maglev train vehicle 4, and the air-core coil 1 is connected to the shielding assembly through a support member 3. Among them, the air-core coil 1 is a coil without an iron core, and the shielding component is a single-layer high-permeability shielding cap 2, or more than two layers of high-permeability shielding caps 2 with different magnetic permeability characteristics, so as to block the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com